stainless steel pricelist

Home

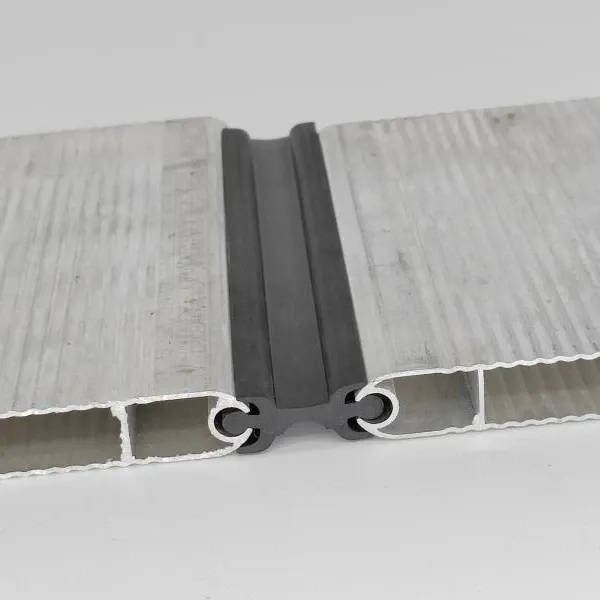

Home- · door seal strip 3m exporter

- · thick door seal strip company

- · gasket seal strip exporters

- · ce cetification front door seal strip

- · led neon moon light supplier

- · led neon ribbon light product

- · pvc white board profile service

- · bathtub seal strip pricelist

- · sponge seal service

- · felt window seal strip suppliers

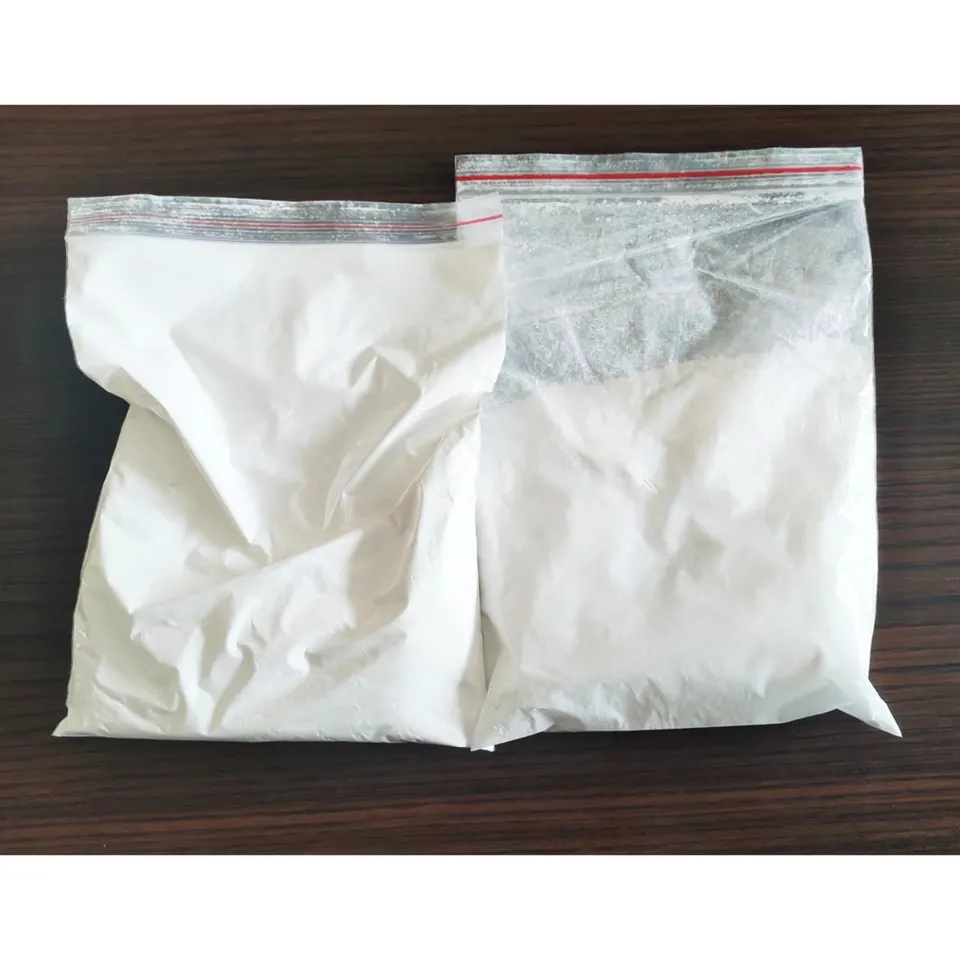

By incorporating titanium dioxide into dyes, manufacturers can achieve a wider range of colors and shades, as well as ensure that the colors remain bright and fade-resistant even after repeated washing or exposure to sunlight By incorporating titanium dioxide into dyes, manufacturers can achieve a wider range of colors and shades, as well as ensure that the colors remain bright and fade-resistant even after repeated washing or exposure to sunlight

By incorporating titanium dioxide into dyes, manufacturers can achieve a wider range of colors and shades, as well as ensure that the colors remain bright and fade-resistant even after repeated washing or exposure to sunlight By incorporating titanium dioxide into dyes, manufacturers can achieve a wider range of colors and shades, as well as ensure that the colors remain bright and fade-resistant even after repeated washing or exposure to sunlight Conductive titanium dioxide may be sourced from specialized manufacturers across the globe Conductive titanium dioxide may be sourced from specialized manufacturers across the globe

Conductive titanium dioxide may be sourced from specialized manufacturers across the globe Conductive titanium dioxide may be sourced from specialized manufacturers across the globe