stainless steel pricelist

Home

Home- · kitchen plinth sealing strip factory

- · shower frame seal strip exporter

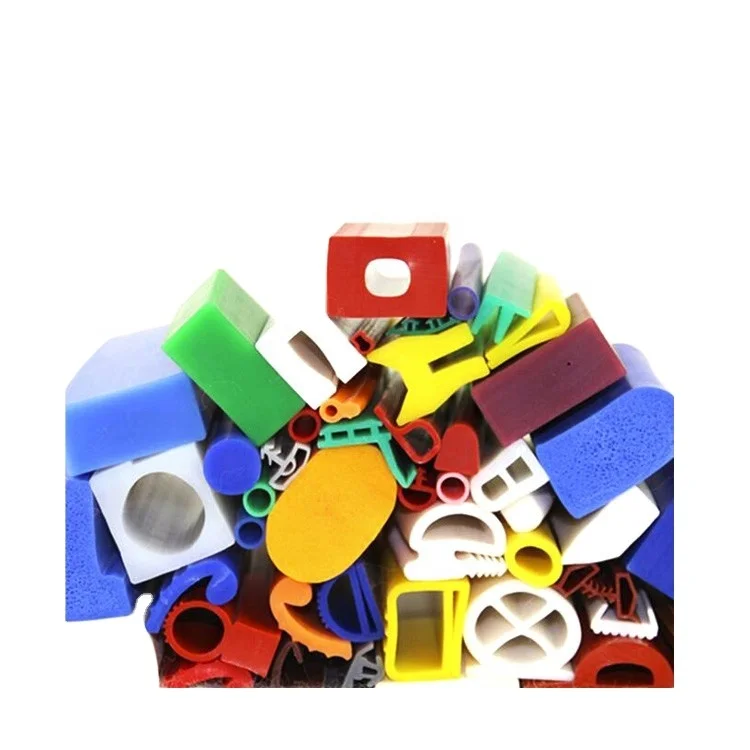

- · sealing strip products

- · d shaped rubber seal strip product

- · oem window rubber seal strip

- · door bottom threshold seal strip pricelist

- · sponge seal tape companies

- · oem door rubber seal strip

- · corner shower door seal strip pricelist

- · silicone rubber plastic strip exporters

It does not react with other ingredients in the food and does not impart any taste or odor It does not react with other ingredients in the food and does not impart any taste or odor

It does not react with other ingredients in the food and does not impart any taste or odor It does not react with other ingredients in the food and does not impart any taste or odor