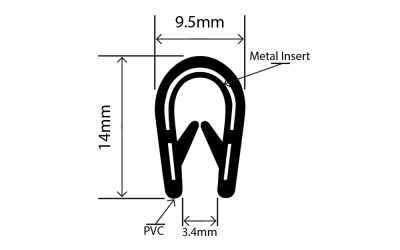

Vertical shower seal strip manufacturers are integral to the design and functionality of modern bathrooms. Their commitment to quality, customization, sustainability, and innovation ensures that consumers have access to the best products on the market. As homeowners continue to prioritize bathrooms as personal sanctuaries, the importance of effective, appealing, and durable shower seal strips cannot be overstated. Choosing the right manufacturer can make all the difference in achieving a leak-free, beautiful, and comfortable bathroom space.

Home

Home