stainless steel pricelist

Home

Home- · door seal strip 3m exporter

- · thick door seal strip company

- · gasket seal strip exporters

- · ce cetification front door seal strip

- · led neon moon light supplier

- · led neon ribbon light product

- · pvc white board profile service

- · bathtub seal strip pricelist

- · sponge seal service

- · felt window seal strip suppliers

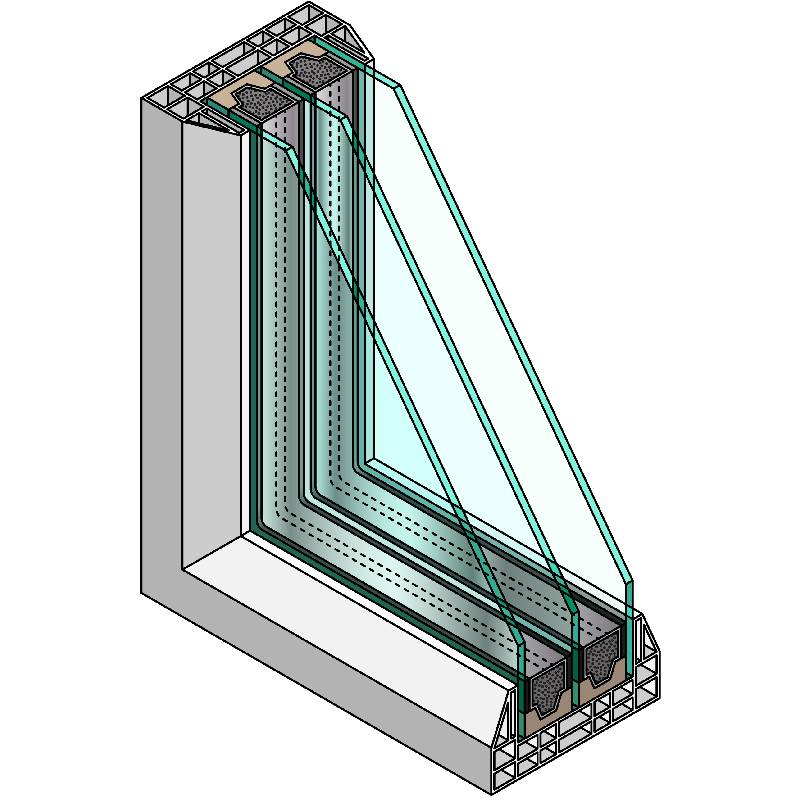

It offers practical benefits such as UV protection and sound insulation, making it a desirable choice for environments that require tranquility amid chaos It offers practical benefits such as UV protection and sound insulation, making it a desirable choice for environments that require tranquility amid chaos

It offers practical benefits such as UV protection and sound insulation, making it a desirable choice for environments that require tranquility amid chaos It offers practical benefits such as UV protection and sound insulation, making it a desirable choice for environments that require tranquility amid chaos The sealed unit is resistant to moisture ingress, preventing fogging or condensation build-up between the panes The sealed unit is resistant to moisture ingress, preventing fogging or condensation build-up between the panes

The sealed unit is resistant to moisture ingress, preventing fogging or condensation build-up between the panes The sealed unit is resistant to moisture ingress, preventing fogging or condensation build-up between the panes

Its high solar reflectance helps in reducing heat absorption, making it an ideal choice for energy-efficient buildings Its high solar reflectance helps in reducing heat absorption, making it an ideal choice for energy-efficient buildings

Its high solar reflectance helps in reducing heat absorption, making it an ideal choice for energy-efficient buildings Its high solar reflectance helps in reducing heat absorption, making it an ideal choice for energy-efficient buildings Unlike some aftermarket screen protectors that can leave a visible film or affect the touch sensitivity of your device, OEM tempered glass provides crystal-clear viewing and responsive touch input Unlike some aftermarket screen protectors that can leave a visible film or affect the touch sensitivity of your device, OEM tempered glass provides crystal-clear viewing and responsive touch input

Unlike some aftermarket screen protectors that can leave a visible film or affect the touch sensitivity of your device, OEM tempered glass provides crystal-clear viewing and responsive touch input Unlike some aftermarket screen protectors that can leave a visible film or affect the touch sensitivity of your device, OEM tempered glass provides crystal-clear viewing and responsive touch input