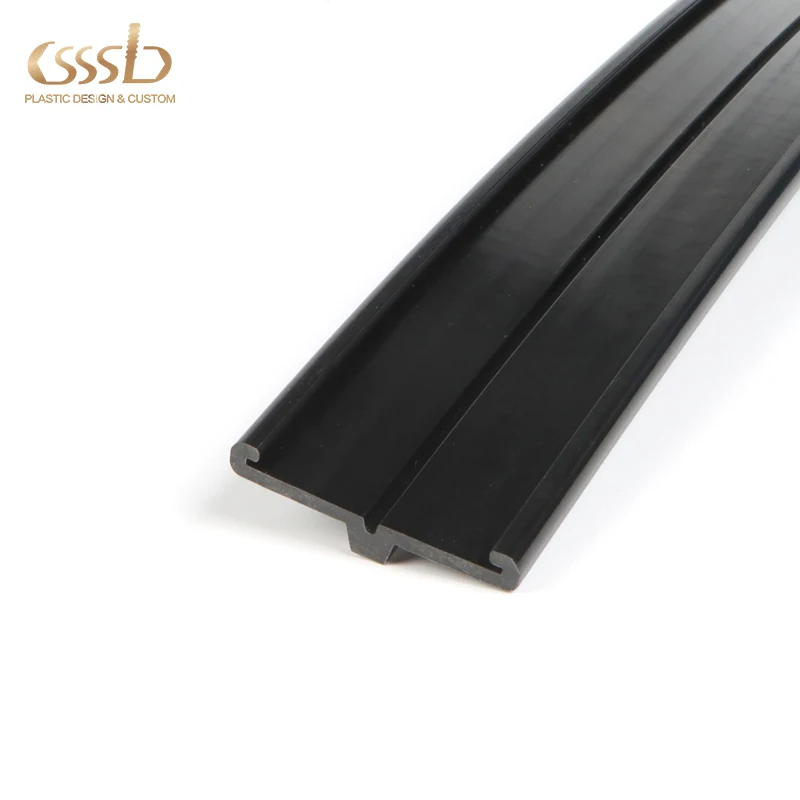

SEG, or Silicone Edge Graphic, silicone strips are specialized materials used primarily in the display and signage industry. These strips are made of high-quality silicone, which gives them excellent elasticity, flexibility, and weather resistance. SEG silicone strips are primarily designed to hold fabric graphics taut within a frame, ensuring a smooth and visually appealing presentation. The edge of the fabric is sewn to a silicone beading, which fits snugly into a groove in the frame, allowing for easy installation and replacement.

Home

Home