stainless steel pricelist

Home

Home- · kitchen plinth sealing strip factory

- · shower frame seal strip exporter

- · sealing strip products

- · d shaped rubber seal strip product

- · oem window rubber seal strip

- · door bottom threshold seal strip pricelist

- · sponge seal tape companies

- · oem door rubber seal strip

- · corner shower door seal strip pricelist

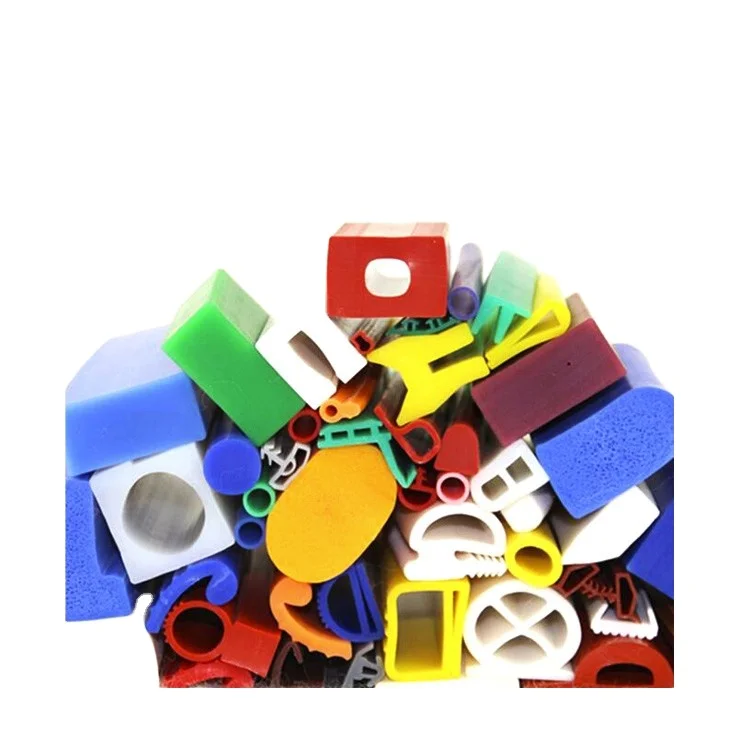

- · silicone rubber plastic strip exporters

. Speed rating, on the other hand, indicates the maximum rotational speed the bearing can withstand. The clearance, or the small gap between the inner and outer rings, affects the bearing's running accuracy and temperature rise during operation.

. Speed rating, on the other hand, indicates the maximum rotational speed the bearing can withstand. The clearance, or the small gap between the inner and outer rings, affects the bearing's running accuracy and temperature rise during operation.

For instance, in wind turbines, where the rotor blades generate significant thrust during operation, these bearings ensure stable rotation and prevent potential damage to the turbine assembly For instance, in wind turbines, where the rotor blades generate significant thrust during operation, these bearings ensure stable rotation and prevent potential damage to the turbine assembly

For instance, in wind turbines, where the rotor blades generate significant thrust during operation, these bearings ensure stable rotation and prevent potential damage to the turbine assembly For instance, in wind turbines, where the rotor blades generate significant thrust during operation, these bearings ensure stable rotation and prevent potential damage to the turbine assembly