In conclusion, the intersection of handmade craftsmanship and CE certification in ABS strips represents a remarkable blend of creativity, safety, and sustainability. As consumers continue to seek meaningful products that embody artistry and compliance with safety standards, handmade ABS strips are poised to occupy a special place in both the marketplace and the hearts of those who cherish unique, responsibly made items. This emerging trend not only celebrates artisanship but also advocates for a more conscientious approach to consumption in the modern world.

Home

Home

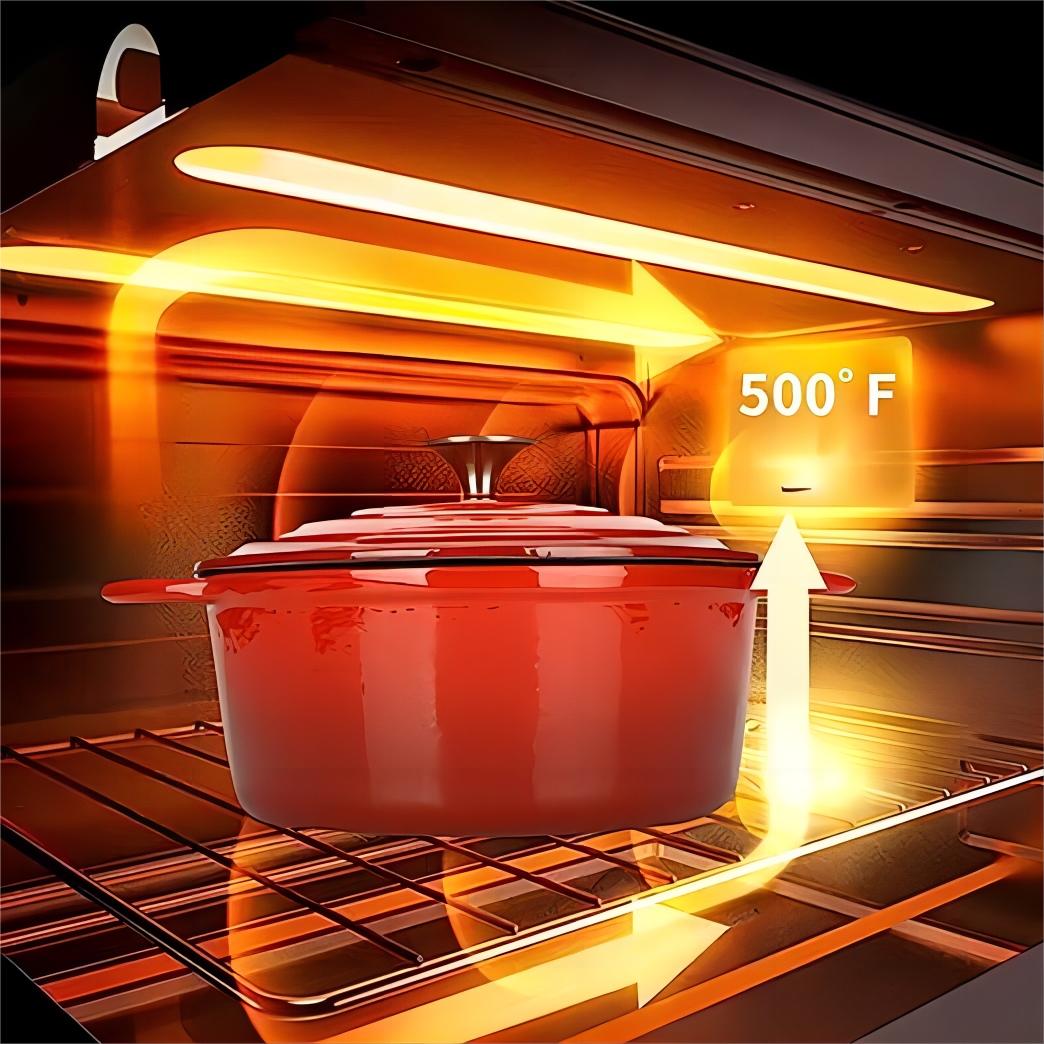

Once heated, it stays hot for extended periods, which is particularly beneficial for slow-cooking recipes or maintaining a consistent temperature during a busy cooking session Once heated, it stays hot for extended periods, which is particularly beneficial for slow-cooking recipes or maintaining a consistent temperature during a busy cooking session

Once heated, it stays hot for extended periods, which is particularly beneficial for slow-cooking recipes or maintaining a consistent temperature during a busy cooking session Once heated, it stays hot for extended periods, which is particularly beneficial for slow-cooking recipes or maintaining a consistent temperature during a busy cooking session