stainless steel pricelist

Home

Home- · door seal strip 3m exporter

- · thick door seal strip company

- · gasket seal strip exporters

- · ce cetification front door seal strip

- · led neon moon light supplier

- · led neon ribbon light product

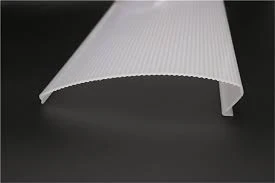

- · pvc white board profile service

- · bathtub seal strip pricelist

- · sponge seal service

- · felt window seal strip suppliers

Workers navigating through construction sites laden with debris and potential sharp objects appreciate the peace of mind that comes with wearing footwear that offers both mobility and protection Workers navigating through construction sites laden with debris and potential sharp objects appreciate the peace of mind that comes with wearing footwear that offers both mobility and protection

Workers navigating through construction sites laden with debris and potential sharp objects appreciate the peace of mind that comes with wearing footwear that offers both mobility and protection Workers navigating through construction sites laden with debris and potential sharp objects appreciate the peace of mind that comes with wearing footwear that offers both mobility and protection