stainless steel pricelist

Home

Home- · door seal strip 3m exporter

- · thick door seal strip company

- · gasket seal strip exporters

- · ce cetification front door seal strip

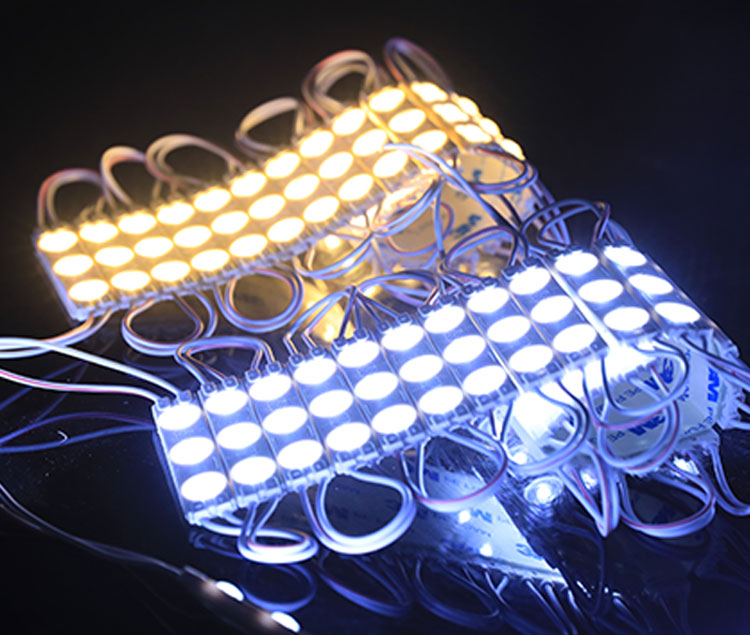

- · led neon moon light supplier

- · led neon ribbon light product

- · pvc white board profile service

- · bathtub seal strip pricelist

- · sponge seal service

- · felt window seal strip suppliers

.

. Its strength and durability ensure passenger safety while maintaining visibility Its strength and durability ensure passenger safety while maintaining visibility

Its strength and durability ensure passenger safety while maintaining visibility Its strength and durability ensure passenger safety while maintaining visibility Frosted glass cabinets with black accents can add a touch of elegance to a kitchen, while a black frosted glass shower door can create a luxurious spa-like atmosphere in a bathroom Frosted glass cabinets with black accents can add a touch of elegance to a kitchen, while a black frosted glass shower door can create a luxurious spa-like atmosphere in a bathroom

Frosted glass cabinets with black accents can add a touch of elegance to a kitchen, while a black frosted glass shower door can create a luxurious spa-like atmosphere in a bathroom Frosted glass cabinets with black accents can add a touch of elegance to a kitchen, while a black frosted glass shower door can create a luxurious spa-like atmosphere in a bathroom