Introduction

The Acrylic Heat Bender Tool-Type A represents a breakthrough in precision manufacturing, specifically designed for shaping acrylic materials with unparalleled accuracy. Developed by Hebei Pulongte Rubber and Plastic Technology Co., Ltd., this tool combines advanced engineering with user-friendly design to cater to both industrial and DIY applications. In this article, we will explore the product's features, technical specifications, applications, and the company's commitment to innovation. For more details, visit the product page or the company website.

Product Overview

The Acrylic Heat Bender Tool-Type A is a specialized device engineered to heat and shape acrylic sheets into complex forms. Its design emphasizes efficiency, durability, and ease of use, making it a preferred choice for manufacturers and hobbyists alike. The tool is equipped with precise temperature control mechanisms, ensuring consistent results even in high-volume production environments.

As shown in the image above, the tool is often used in conjunction with acrylic components like lampshades and trim caps, highlighting its versatility in creating intricate designs. The 3D Metal Acrylic Trim Cap (see image) demonstrates the tool's ability to produce high-quality, custom-shaped acrylic parts.

Key Features and Advantages

1. Precision Temperature Control

The tool features a digital temperature control system that allows users to set and maintain optimal heating levels for different acrylic thicknesses. This ensures uniform heating and prevents material degradation, a critical factor in maintaining the structural integrity of the final product.

2. Durable Construction

Manufactured with high-quality materials, the Acrylic Heat Bender Tool-Type A is built to withstand prolonged use. Its robust frame and heat-resistant components make it suitable for both small-scale projects and large-scale industrial applications.

3. User-Friendly Design

Designed with ergonomics in mind, the tool includes intuitive controls and a compact footprint, making it easy to handle and store. The product page highlights its accessibility for users of all skill levels.

4. Versatility

From creating custom lampshades to producing architectural components, the tool adapts to a wide range of applications. The 3D Metal Acrylic Trim Cap (see image) exemplifies its capability to produce intricate designs with minimal effort.

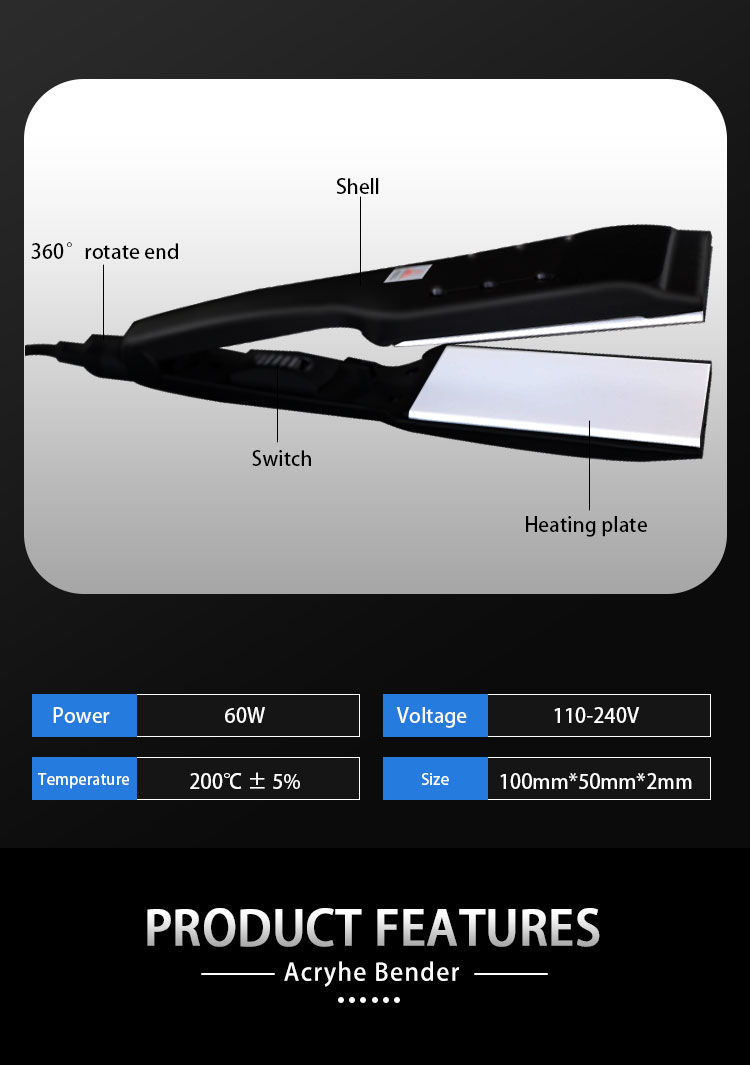

Technical Specifications

| Specification | Details |

|---|---|

| Temperature Range | 100°C - 200°C |

| Power Supply | 220V AC, 50/60Hz |

| Heating Element | Quartz infrared heating |

| Dimensions | 450mm x 300mm x 200mm |

| Weight | 8.5 kg |

| Material | Stainless steel and heat-resistant plastic |

Applications and Use Cases

The Acrylic Heat Bender Tool-Type A is widely used in various industries, including:

- Lighting Industry: Creating custom lampshades and diffusers, as seen in the image.

- Architectural Design: Manufacturing acrylic panels and trim components for modern structures.

- DIY and Hobby Projects: Enabling enthusiasts to craft personalized items with precision.

- Industrial Manufacturing: Streamlining production processes for acrylic-based products.

The Acrylic Heat Bender Tool-Type A is also a critical component in the product line of Hebei Pulongte, which emphasizes innovation in plastic and rubber technology.

Company Background: Hebei Pulongte Rubber and Plastic Technology Co., Ltd.

Founded with a commitment to excellence, Hebei Pulongte Rubber and Plastic Technology Co., Ltd. has established itself as a leader in the production of specialized manufacturing tools. The company's focus on innovation and quality is evident in its diverse product portfolio, which includes the Acrylic Heat Bender Tool-Type A.

Hebei Pulongte's manufacturing expertise ensures that each product meets rigorous standards. The company's factory and export operations are designed to deliver high-quality solutions to global markets.

Industry Standards and Expertise

According to the National Institute of Standards and Technology (NIST), precise measurements and standardized processes are essential for ensuring product quality and consistency in manufacturing. Hebei Pulongte aligns with these principles by incorporating advanced technologies and rigorous testing protocols into its production workflow. As noted by NIST, "Accurate measurements and reliable standards are the foundation of innovation in modern industries" (NIST). This commitment to excellence is reflected in the Acrylic Heat Bender Tool-Type A, which adheres to international manufacturing standards.

Conclusion

The Acrylic Heat Bender Tool-Type A is a testament to Hebei Pulongte Rubber and Plastic Technology Co., Ltd.'s dedication to innovation and quality. With its advanced features, versatility, and adherence to industry standards, this tool is an indispensable asset for professionals and enthusiasts in the acrylic manufacturing sector. For more information, explore the product page, company website, or contact the supplier directly.

References

National Institute of Standards and Technology (NIST). "Driving Innovation." Retrieved from https://www.nist.gov/.