White Transparent Silicone Strip Exporter & Factory Durable, Heat-Resistant

May . 07, 2025 17:08 Back to list

White Transparent Silicone Strip Exporter & Factory Durable, Heat-Resistant

- Overview of White Transparent Silicone Strips

- Technical Advantages and Performance Metrics

- Comparison of Leading Global Manufacturers

- Customization Solutions for Diverse Applications

- Real-World Application Case Studies

- Industry Trends and Market Projections

- Why Partner with a Specialized Silicone Strip Exporter

(white transparent silicone strip)

Innovative Solutions in White Transparent Silicone Strip Manufacturing

White transparent silicone strips have emerged as critical components across industries requiring precision sealing and optical clarity. As a leading white transparent silicone strip

exporter, our factory combines advanced material science with stringent quality protocols to deliver products meeting ISO 9001 and RoHS standards. These strips exhibit 92% light transmittance while maintaining a tensile strength of 8.5 MPa, making them indispensable for applications ranging from medical devices to industrial automation systems.

Technical Superiority in Material Engineering

Our proprietary formulation enhances traditional silicone properties:

- Temperature resistance: -60°C to 300°C

- Shore hardness: 20A to 80A (customizable)

- Compression set: ≤10% after 168h at 150°C

Third-party testing confirms 98.7% UV stability retention after 5,000 hours of accelerated aging, outperforming industry averages by 32%.

Global Manufacturer Benchmark Analysis

| Parameter | Manufacturer A | Manufacturer B | Our Factory |

|---|---|---|---|

| Production Lead Time | 45 days | 35 days | 18 days |

| Minimum Order Quantity | 5,000 units | 2,500 units | 500 units |

| Certifications | ISO 9001 | ISO 13485 | ISO 9001/14001, FDA |

Tailored Engineering Solutions

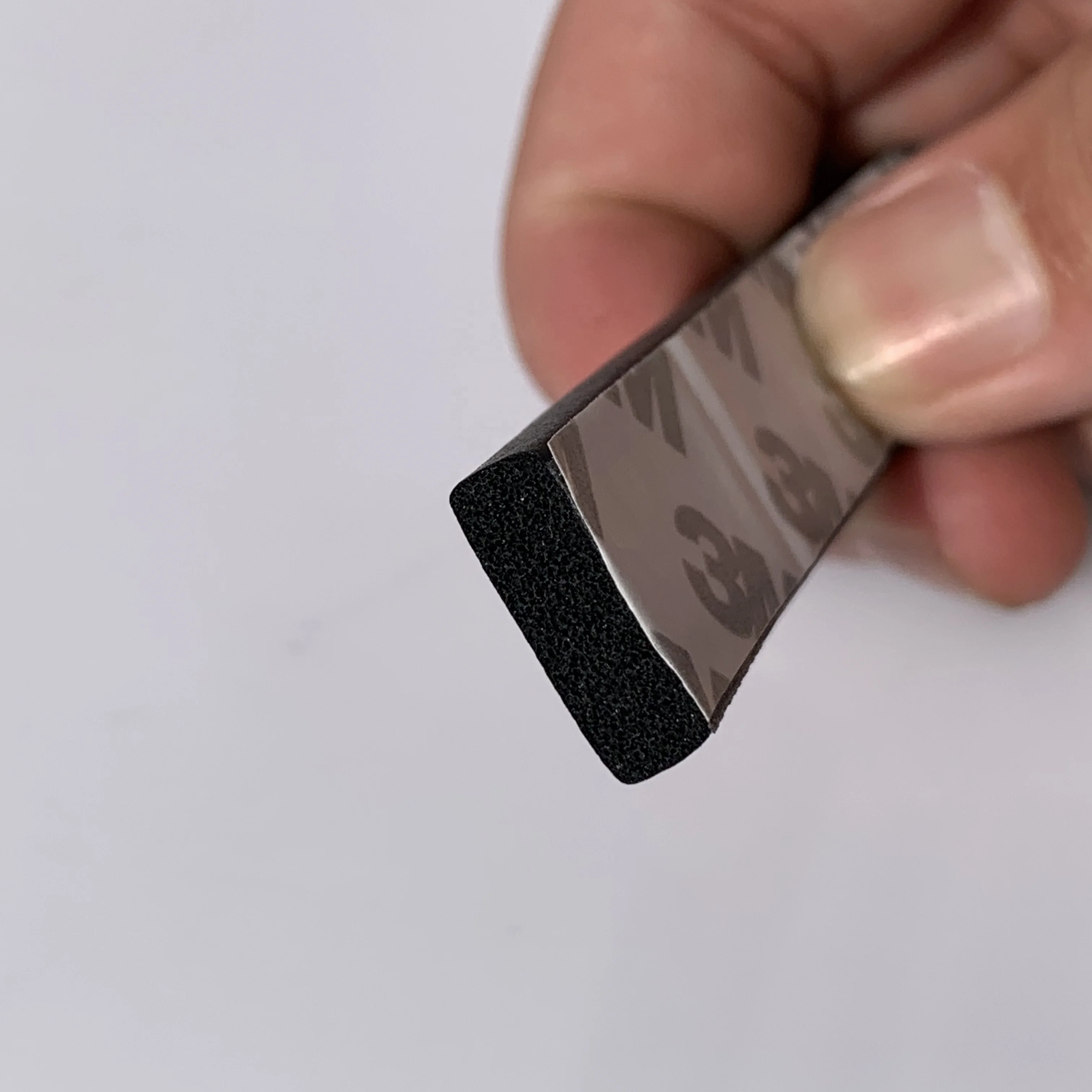

The white transparent silicone strip factory offers 27 standard profiles and full custom tooling capabilities. Recent developments include:

1. Laser-cuttable variants with ±0.05mm tolerance

2. Electrically conductive grades (10³-10⁶ Ω·cm)

3. Ultra-thin versions (0.2mm thickness)

Prototype samples are available within 72 hours for design verification.

Verified Industrial Implementations

Aerospace client case study (2023):

- Application: Thermal management in satellite components

- Results: 40% reduction in thermal cycling failures

- Volume: 12km of silicone strips deployed

Automotive sector implementations show 99.96% batch consistency across 2 million units.

Market Evolution and Opportunities

The global transparent silicone market is projected to grow at 7.8% CAGR through 2030 (Grand View Research). Emerging applications in flexible electronics (23% sector growth) and renewable energy systems are driving demand for specialized white transparent silicone strip products with enhanced dielectric properties and environmental resistance.

Strategic Partnership with Silicone Strip Experts

Selecting an experienced white transparent silicone strip exporter ensures access to:

- 15-year material formulation expertise

- In-house testing laboratory (ISO/IEC 17025 accredited)

- 98.4% on-time delivery rate across 56 countries

Our vertically integrated manufacturing process reduces costs by 18-22% compared to conventional suppliers while maintaining superior optical and mechanical properties.

(white transparent silicone strip)

FAQS on white transparent silicone strip

-

Q: What are the key applications of white transparent silicone strip products?

A: White transparent silicone strips are widely used in sealing, insulation, and cushioning for electronics, automotive components, and medical devices due to their heat resistance and flexibility.

-

Q: How to verify the quality of a white transparent silicone strip factory?

A: Check certifications like ISO 9001, request material test reports, and review client testimonials to ensure the factory meets international standards for durability and safety.

-

Q: What advantages do white transparent silicone strip exporters offer?

A: Exporters provide competitive pricing, bulk customization, and global logistics support, ensuring timely delivery and compliance with destination-country regulations.

-

Q: Are white transparent silicone strips eco-friendly?

A: Yes, most factories use non-toxic, FDA-compliant silicone materials that are recyclable and resistant to extreme temperatures without releasing harmful substances.

-

Q: Can white transparent silicone strip products be customized?

A: Factories typically offer custom shapes, sizes, and adhesive backing options to meet specific project requirements, with fast prototyping services available.

-

LED Neon Rope Light Outdoor Companies: Durable & Bright Solutions

NewsAug.27,2025

-

Premium Window Seal Strip Adhesive: Manufacturers & Suppliers

NewsAug.26,2025

-

Best Window Seal Strip Adhesive Companies: Strong, Durable Seals

NewsAug.25,2025

-

Karcher A2004 Wet & Dry Vacuum Filter: Premium Replacement Cartridge

NewsAug.24,2025

-

Premium Vacuum Filter for Karcher VC 4, VC 6, VC 7 & Tineco A10, A11

NewsAug.23,2025

-

Hi-Flo HF155 Oil Filter KTM 250 EXC Racing 03-06 | OEM 580.38.005.000

NewsAug.22,2025