J Type & Arrow Type Channel Letter Companies | OEM LED Signs

Oct . 16, 2025 14:35 Back to list

J Type & Arrow Type Channel Letter Companies | OEM LED Signs

How j type and arrow type channel letter companies are quietly winning with better sealing

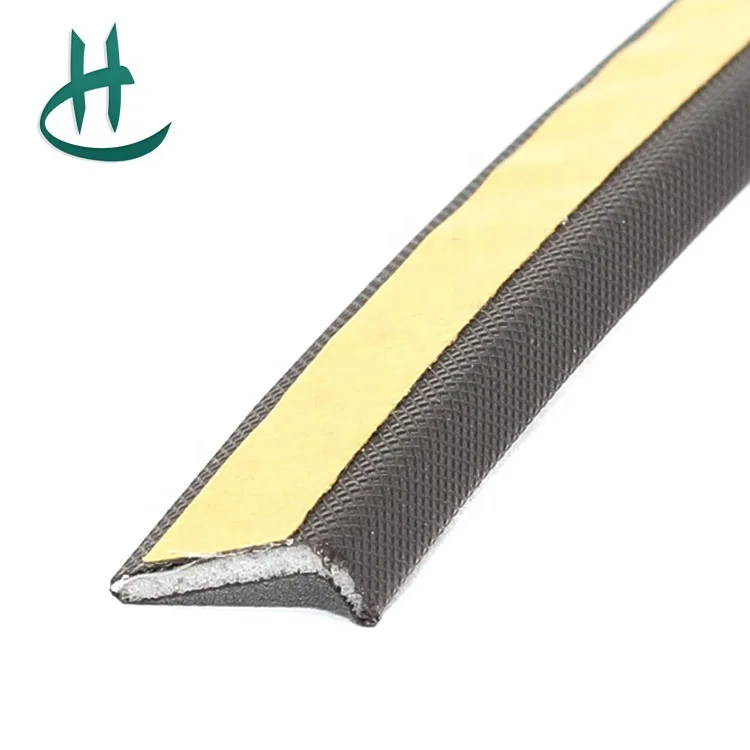

If you’ve spent nights chasing micro-leaks in a backer plate, you know: great channel letters live and die by their gaskets. Lately, I’ve seen j type and arrow type channel letter companies move from “good enough foam” to engineered elastomers—most often neoprene—because field failures are expensive. Actually, a simple upgrade like a precision-cut neoprene rubber gasket (the long name: “neoprene rubber gasket with customized size and color sealing water and rubber flange gasket”) can turn IP worries into a non-issue.

Why neoprene for channel letters?

Neoprene (CR) balances oil resistance, weatherability, and compressibility. For j-type and arrow-type returns, it cushions acrylic faces, seals raceway penetrations, and keeps LED drivers dry. Many customers say it “just seats better” than commodity foams. To be honest, the fewer callbacks, the better the margins.

Typical specs (real-world use may vary)

| Parameter | Typical value | Notes |

|---|---|---|

| Material | Neoprene (CR), ASTM D2000 BC/BE | Sign industry standard blend |

| Hardness | 60 ±5 Shore A | ASTM D2240 |

| Thickness range | 1–20 mm | CNC/waterjet/die-cut |

| Tensile strength | ≥8 MPa | ISO 37 |

| Elongation @ break | ≥250% | ISO 37 |

| Compression set | ≤25% (22h @70°C) | ISO 815-1 |

| Temp range | ≈ -30 to +100°C (short +120°C) | Sign cabinets, outdoor |

| Sealing level | Up to IP65–IP66 | With proper design, IEC 60529 |

| Color options | Black standard; custom RAL | Brand matching |

| Adhesive | PSA backing optional | 3M-type tapes available |

Where it fits in the build

- Face-to-return seals on j-type and arrow-type letters

- Backer plate interfaces; raceway and wall penetrations

- Grommet-style isolation for LED wiring and power supplies

For compliance-minded shops (think UL 48), consistent compression and repeatable thickness matter more than people admit. I guess that’s why j type and arrow type channel letter companies care about test data now.

Process flow, testing, and service life

Material selection (CR per ASTM D2000) → sheet calendering → CNC/waterjet/die-cutting → deburring → optional PSA lamination → dimensional check → hardness, tensile and elongation tests (ASTM D2240, ISO 37) → compression set (ISO 815) → fit check on your letter profile. Field results typically show 5–10 years outdoor life, depending on UV and cleaners used. Origin: Xiangjiang Street South, Jinggangshan Road west, Qinghe County, Xingtai City, Hebei Province.

| Vendor | Customization | MOQ | Lead time | Testing/Certs | Warranty |

|---|---|---|---|---|---|

| Pulongte (CR gaskets) | Sizes/colors, CNC/waterjet | ≈100 pcs | 7–12 days | ASTM/ISO, RoHS/REACH | 12 months |

| Vendor A (importer) | Limited thickness only | ≈500 pcs | 3–5 weeks | Basic hardness check | 6 months |

| Vendor B (reseller) | Stock only | ≈50 pcs | 2–3 days | None stated | 0–3 months |

Field notes and mini case studies

Coastal QSR retrofit: After storms kept wicking water into arrow-type returns, a Florida installer switched to 3 mm CR gaskets with PSA. Result: IP66 pass on-site splash tests and zero LED driver failures for 14 months.

Stadium letters: Large-format j-type letters used 5 mm closed-profile CR strip, die-cut corners, and rivnut compression. Techs report faster face re-seating and fewer “mystery drips.” Surprisingly simple fix.

Trends to watch

- Higher IP ratings on spec sheets (UL 48 inspections take note).

- Brand-color gaskets for visible seams—small detail, big perception.

- Cleaner adhesives; RoHS/REACH documentation requested more often.

- Some shift to EPDM in high-UV regions, but j type and arrow type channel letter companies still favor neoprene for balance of properties.

Bottom line: if you’re speccing new letters or retrofitting, a properly tested neoprene gasket is a small line item that protects the entire installation. In fact, it’s one of those low-drama upgrades that keeps your phone from ringing.

Authoritative citations

- UL 48: Standard for Electric Signs — https://standardscatalog.ul.com/standards/en/standard_48

- IEC 60529: IP Code — https://www.iec.ch/ip-ratings

- ASTM D2000: Classification for Rubber Products — https://www.astm.org/d2000

- ISO 37: Rubber, Determination of tensile stress-strain — https://www.iso.org/standard/77802.html

- ISO 815-1: Compression set of rubber — https://www.iso.org/standard/67402.html

- ASTM D2240: Standard Test Method for Rubber Hardness — https://www.astm.org/d2240

-

Comprehensive Guide to White PVC Material: Benefits, Applications & Innovations

NewsNov.24,2025

-

Flat Hard Plastic PP Flexible Strips: Durable, Flexible, and Sustainable Solutions for Modern Industry

NewsNov.24,2025

-

Understanding Soft PVC Slip Cover Tuck Grip – Global Uses & Benefits

NewsNov.23,2025

-

Discover the Practical Benefits and Global Use of Square Plastic Tubes

NewsNov.23,2025

-

Understanding Led Lampshade Diffuser PC Covers – Benefits, Trends & Buying Guide

NewsNov.22,2025

-

Durable, Cost-Effective PVC Rectangular Grey Tube for Frame Solutions | Pulongte

NewsNov.22,2025