Acrylic Heat Bender Tool-Type A-Hebei Pulongte Rubber and Plastic Technology Co., Ltd.|Precision Acrylic Bending, Industrial Innovation

Sep . 19, 2025 21:05 Back to list

Acrylic Heat Bender Tool-Type A-Hebei Pulongte Rubber and Plastic Technology Co., Ltd.|Precision Acrylic Bending, Industrial Innovation

Acrylic materials have become indispensable in modern manufacturing, finding applications in lighting, signage, automotive components, and architectural design. However, shaping acrylic into complex forms requires specialized tools that balance precision, efficiency, and durability. The Acrylic Heat Bender Tool-Type A emerges as a revolutionary solution, designed to meet the demands of both industrial and artisanal applications. This article explores the tool’s features, technical specifications, use cases, and the company behind its innovation—Hebei Pulongte Rubber and Plastic Technology Co., Ltd..

Product Overview

The Acrylic Heat Bender Tool-Type A is a high-precision device engineered to bend acrylic sheets with minimal effort and maximum accuracy. Unlike traditional methods that rely on manual heating and bending, this tool integrates advanced thermal control and ergonomic design to streamline the process. The tool’s versatility allows it to handle a wide range of acrylic thicknesses, making it a preferred choice for manufacturers and hobbyists alike.

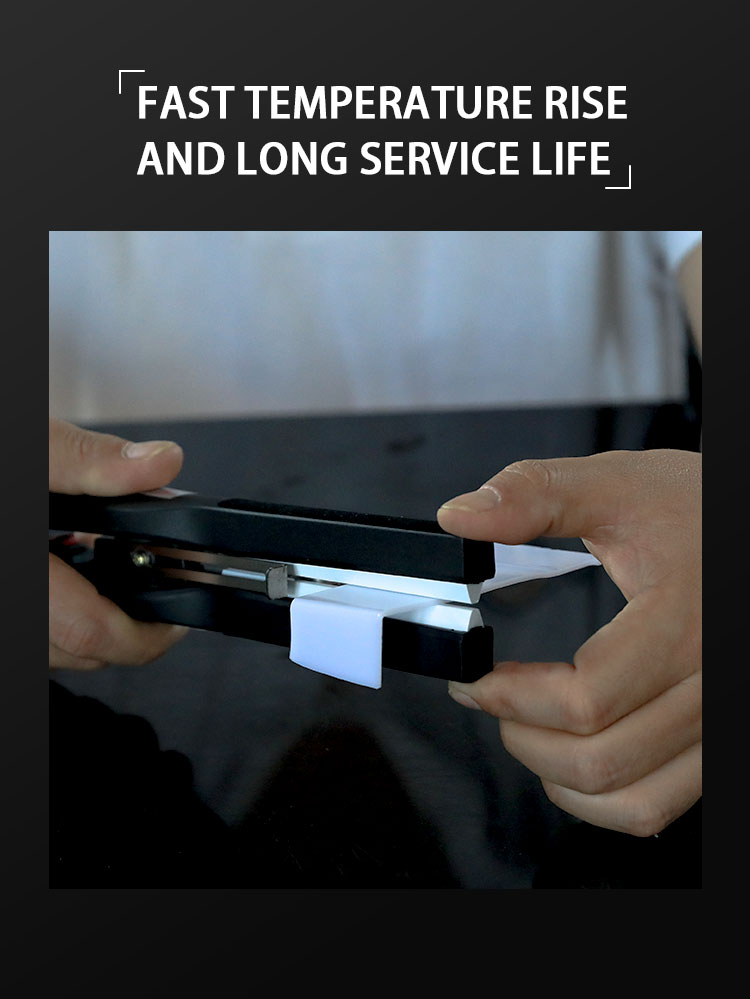

Figure 1: Acrylic Heat Bender Tool-Type A in action

Key Features and Advantages

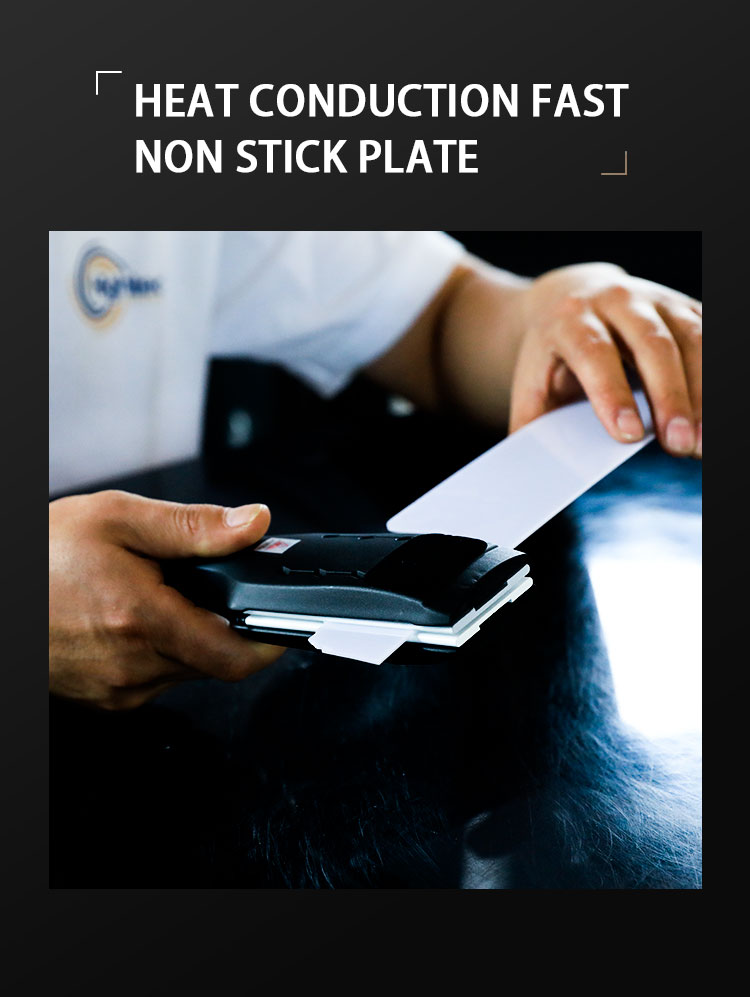

The Acrylic Heat Bender Tool-Type A distinguishes itself through several innovative features:

- Advanced Thermal Control: The tool employs a precision temperature regulation system, ensuring consistent heat distribution to prevent warping or cracking of the acrylic material.

- Ergonomic Design: Its lightweight and contoured handle reduce user fatigue, making it ideal for extended use in industrial settings or DIY projects.

- Multi-Thickness Compatibility: The tool can handle acrylic sheets ranging from 1mm to 10mm in thickness, catering to diverse manufacturing needs.

- Quick Heating and Cooling: Rapid heat-up times and efficient cooling mechanisms enhance productivity and minimize downtime.

- Durable Construction: Built with high-quality materials, the tool is resistant to wear and tear, ensuring long-term reliability.

Technical Specifications

| Parameter | Specification |

|---|---|

| Maximum Acrylic Thickness | 10mm |

| Operating Temperature Range | 150°C - 250°C |

| Power Supply | 110V/220V AC |

| Weight | 1.2kg |

| Dimensions | 300mm x 150mm x 100mm |

| Material of Construction | Aluminum Alloy and Heat-Resistant Plastic |

Applications in Industry and Beyond

The Acrylic Heat Bender Tool-Type A is a versatile tool with applications across multiple industries:

1. Lighting and Interior Design

Acrylic is widely used in creating lampshades, light covers, and decorative panels. The tool enables the production of intricate shapes, such as the Light Cover Acrylic Lampshade shown in the image below, which combines aesthetic appeal with functional lighting.

Figure 2: Light Cover Acrylic Lampshade

2. Automotive and Aerospace

In the automotive industry, acrylic is used for dashboards, windows, and signage. The tool’s precision ensures that components meet stringent quality standards. Similarly, in aerospace, it aids in manufacturing lightweight, durable parts.

3. Signage and Advertising

Custom-shaped acrylic signs and displays require precise bending. The Acrylic Heat Bender Tool-Type A allows for the creation of curved or angled signs, enhancing visual impact and brand visibility.

4. Art and Craft

Artisans and hobbyists benefit from the tool’s user-friendly design, enabling them to create unique acrylic sculptures, jewelry, and decorative items without specialized training.

Company Background: Hebei Pulongte Rubber and Plastic Technology Co., Ltd.

Founded with a commitment to innovation and quality, Hebei Pulongte Rubber and Plastic Technology Co., Ltd. has established itself as a leader in the production of industrial tools and materials. The company specializes in manufacturing high-performance products for the plastics and rubber industries, with a focus on customer-centric solutions.

Figure 3: Hebei Pulongte Rubber and Plastic Technology Co., Ltd.

Hebei Pulongte’s dedication to research and development ensures that its products, like the Acrylic Heat Bender Tool-Type A, meet global standards. The company adheres to rigorous quality control measures, as highlighted by the National Institute of Standards and Technology (NIST)’s guidelines on industrial manufacturing processes. According to NIST, "Precision in tooling and material handling is critical to maintaining product integrity and reducing waste in production workflows" (NIST, 2023). Hebei Pulongte’s tools exemplify this principle, offering reliable performance and consistency.

Why Choose the Acrylic Heat Bender Tool-Type A?

Several factors make the Acrylic Heat Bender Tool-Type A a standout choice:

- Cost-Effectiveness: By reducing material waste and labor time, the tool lowers overall production costs.

- Time Efficiency: Its rapid heating and cooling cycles significantly shorten the bending process.

- Consistency: The tool ensures uniform bends, minimizing the need for rework.

- Scalability: Suitable for both small-scale projects and large-scale manufacturing.

Conclusion

The Acrylic Heat Bender Tool-Type A represents a significant advancement in acrylic fabrication technology. Its combination of precision, durability, and ease of use makes it an essential tool for professionals and enthusiasts alike. Backed by the expertise of Hebei Pulongte Rubber and Plastic Technology Co., Ltd., this tool sets a new benchmark for efficiency in the plastics industry. As highlighted by NIST’s research on industrial standards, "Innovative tools like the Acrylic Heat Bender Tool-Type A play a vital role in enhancing productivity and quality in manufacturing sectors" (NIST, 2023). Whether you are producing lighting fixtures, automotive components, or artistic pieces, this tool offers the versatility and reliability needed to succeed.

References

National Institute of Standards and Technology (NIST). (2023). Industrial Manufacturing Standards and Best Practices. Retrieved from https://www.nist.gov

Figure 4: 3D Metal Acrylic Trim Cap

Figure 5: 3D Metal Acrylic Trim Cap

Figure 6: 3D Metal Acrylic Trim Cap

Figure 7: Acrylic Heat Bender Tool-Type A Supplier

Figure 8: Acrylic Heat Bender Tool-Type A Factory

Figure 9: Acrylic Heat Bender Tool-Type A Exporter

Figure 10: Acrylic Heat Bender Tool-Type A Pricelist

-

Comprehensive Guide to White PVC Material: Benefits, Applications & Innovations

NewsNov.24,2025

-

Flat Hard Plastic PP Flexible Strips: Durable, Flexible, and Sustainable Solutions for Modern Industry

NewsNov.24,2025

-

Understanding Soft PVC Slip Cover Tuck Grip – Global Uses & Benefits

NewsNov.23,2025

-

Discover the Practical Benefits and Global Use of Square Plastic Tubes

NewsNov.23,2025

-

Understanding Led Lampshade Diffuser PC Covers – Benefits, Trends & Buying Guide

NewsNov.22,2025

-

Durable, Cost-Effective PVC Rectangular Grey Tube for Frame Solutions | Pulongte

NewsNov.22,2025