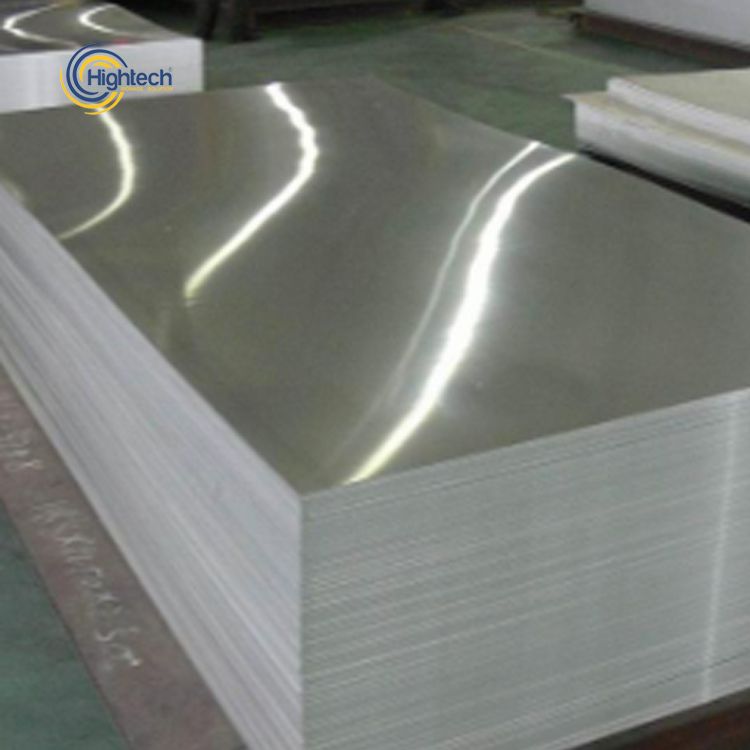

Durable Aluminum Sheet: High-Quality Alloys for Versatile Use

Sep . 12, 2025 08:20 Back to list

Durable Aluminum Sheet: High-Quality Alloys for Versatile Use

In the rapidly evolving landscape of industrial materials, the demand for high-performance, lightweight, and sustainable solutions has never been more critical. At the forefront of this innovation is the Aluminum Sheet, a versatile product essential across numerous B2B sectors. Its unique combination of strength, corrosion resistance, thermal conductivity, and recyclability positions it as a preferred material for engineers and procurement specialists seeking to optimize efficiency and reduce environmental impact. This comprehensive overview delves into the technical intricacies, application diversity, and strategic advantages of this indispensable material.

Industry Trends and Market Dynamics for Aluminum Sheet

The global market for Aluminum Sheet is experiencing significant growth, driven by key industry trends focused on lightweighting, sustainability, and advanced manufacturing. The automotive sector, particularly electric vehicle (EV) production, is a major catalyst, where aluminum sheets are vital for battery enclosures, body panels, and structural components to extend range and improve performance. Similarly, the aerospace industry continues its reliance on high-strength aluminum alloys for aircraft skins and internal structures due to their unparalleled strength-to-weight ratio.

Furthermore, the construction industry is embracing aluminum for facades, roofing, and decorative elements due to its durability, low maintenance, and aesthetic versatility. The increasing emphasis on circular economy principles also bolsters demand, as aluminum is 100% recyclable without degradation of properties, aligning with corporate sustainability goals. Innovations in alloy development, surface treatments, and digital manufacturing (e.g., additive manufacturing integration for tooling) are continuously expanding the application potential of aluminum sheets, making them a cornerstone material for future-proof engineering solutions.

Detailed Manufacturing Process Flow of Aluminum Sheet

The production of high-quality Aluminum Sheet involves a series of meticulously controlled stages, ensuring the final product meets stringent performance and dimensional requirements for various industrial applications.

- 1. Material Selection and Preparation:

- Raw Materials: High-purity aluminum ingots (e.g., 99.7% A00 grade) are selected, often blended with specific alloying elements such as magnesium (Mg), silicon (Si), manganese (Mn), copper (Cu), and zinc (Zn) to achieve desired mechanical and chemical properties for various alloy series (e.g., 1xxx, 3xxx, 5xxx, 6xxx).

- Melting: Ingots and alloy elements are melted in furnaces, typically induction or reverbatory, at temperatures around 700-750°C. Careful control of temperature and atmosphere minimizes impurities and gas absorption.

- Direct Chill (DC) Casting: Molten aluminum is poured into a water-cooled mold, forming large rectangular ingots or "slabs." This rapid cooling ensures a fine, uniform grain structure crucial for subsequent processing and final material performance.

- Heat Treatment: The cast slabs undergo a high-temperature heat treatment (e.g., 500-600°C for several hours). This process homogenizes the alloy structure, dissolving segregations and promoting uniform distribution of alloying elements, which enhances workability and mechanical properties.

- Initial Reduction: Homogenized slabs are heated again and passed through a series of heavy-duty rolling mills. This progressively reduces their thickness (often from 600mm to 6mm or less) while increasing their length. Hot rolling refines the grain structure and improves ductility.

- Precision Thinning: The hot-rolled coils are then transferred to cold rolling mills. This process occurs at room temperature, further reducing thickness to the desired gauge (e.g., 0.2mm to 6mm), improving surface finish, and significantly enhancing mechanical properties such as tensile strength and hardness through work hardening.

- Property Adjustment: Depending on the required temper (e.g., O for soft, H14 for half-hard, T6 for solution heat-treated and artificially aged), the material undergoes specific heat treatments. Annealing softens the material, making it more ductile for subsequent forming, while solution treatment and artificial aging (for heat-treatable alloys) significantly increase strength.

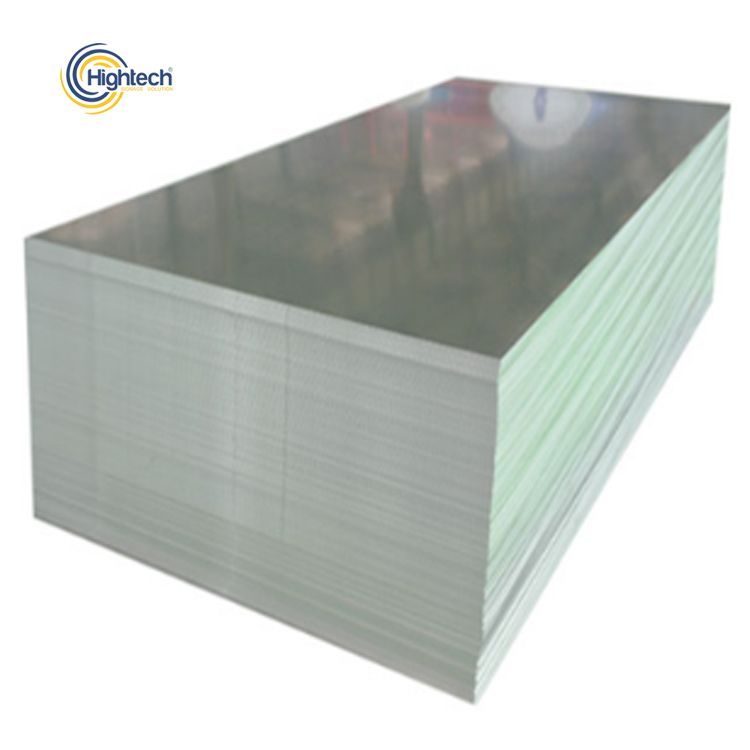

- Slitting and Leveling: The rolled coils are precisely slit to specified widths and cut into sheets of desired lengths. Leveling processes ensure flatness and remove internal stresses.

- Surface Treatment: Options include mill finish, anodizing, brushing, or polishing, depending on the application's aesthetic and protective requirements.

- Testing Standards: Throughout the process, rigorous testing is conducted, adhering to international standards such as ISO 9001, ASTM B209 (Standard Specification for Aluminum and Aluminum-Alloy Sheet and Plate), EN 485 (Aluminium and aluminium alloys - Sheet, strip and plate), and JIS H4000. These tests cover chemical composition, mechanical properties (tensile strength, yield strength, elongation), dimensional tolerances, and surface quality.

Service Life: A properly specified and maintained Aluminum Sheet can offer a service life of several decades, often exceeding 50 years in benign environments, due to its inherent corrosion resistance and robust material properties.

Target Industries & Advantages: Our aluminum sheets find extensive use in industries such as petrochemical, metallurgy, water supply & drainage, automotive, aerospace, construction, and electronics. Key advantages demonstrated in typical application scenarios include:

- Energy Saving: Significant weight reduction in vehicles and aircraft leads to improved fuel efficiency and reduced emissions. In HVAC systems, its high thermal conductivity aids heat exchange efficiency.

- Corrosion Resistance: Formation of a passive oxide layer protects the material from environmental degradation, crucial for marine and outdoor architectural applications.

- Sustainability: High recyclability reduces the environmental footprint and promotes resource efficiency.

Technical Specifications and Material Data

Understanding the precise technical specifications of Aluminum Sheet is paramount for engineers and designers to ensure optimal performance in specific applications. Our product offerings adhere to global standards, providing reliable and consistent material properties.

Table 1: Common Aluminum Sheet Alloys and Their Mechanical Properties

| Alloy | Temper | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) (min) | Hardness (HB) | Main Applications |

|---|---|---|---|---|---|---|

| 1050 | O | 70-100 | 20-40 | 20 | 22 | Chemical equipment, food industry, decorative trim |

| 3003 | H14 | 140-190 | 120-160 | 8 | 40 | Cookware, chemical tanks, pressure vessels |

| 5052 | H32 | 210-260 | 145-215 | 12 | 60 | Marine, automotive, electronics chassis |

| 6061 | T6 | 290-325 | 240-275 | 10 | 95 | Structural components, aerospace, automotive parts |

Table 2: Standard Dimensional Tolerances (per ASTM B209 for Sheet and Plate)

| Nominal Thickness (mm) | Thickness Tolerance (mm) (+/-) | Width Tolerance (mm) (+/-) up to 1500mm | Length Tolerance (mm) (+/-) up to 3000mm | Flatness (mm/m) |

|---|---|---|---|---|

| 0.5 - 1.0 | 0.04 - 0.05 | 1.5 | 3.0 | 2.0 |

| 1.0 - 2.0 | 0.05 - 0.08 | 2.0 | 4.0 | 1.5 |

| 2.0 - 6.0 | 0.08 - 0.15 | 2.5 | 5.0 | 1.0 |

Versatile Application Scenarios

The adaptability of Aluminum Sheet allows for its integration into a remarkably diverse range of industries and critical applications. Its characteristics directly address many modern engineering challenges.

- Automotive Industry: Used extensively for body panels, chassis components, battery enclosures for EVs, heat exchangers, and structural elements. The lightweighting benefits directly translate to improved fuel economy for internal combustion engine vehicles and extended range for electric vehicles, while its excellent thermal management properties are critical for battery performance.

- Aerospace & Aviation: Forming fuselage skins, wing structures, internal components, and fuel tanks. Its high strength-to-weight ratio is indispensable for reducing aircraft mass, thereby increasing payload capacity and fuel efficiency. Specialized alloys like 2xxx and 7xxx series are often used here.

- Construction & Architecture: Applied in roofing, siding, curtain walls, decorative panels, and structural framework. Its superior corrosion resistance, long service life, and aesthetic versatility make it ideal for modern, sustainable building designs, offering resistance to weathering and UV radiation.

- Marine Applications: Employed in shipbuilding for hulls, superstructures, decks, and offshore platform components. Aluminum’s natural resistance to saltwater corrosion and lighter weight compared to steel significantly enhance vessel performance, speed, and fuel efficiency.

- Electronics & Electrical: Critical for heat sinks, electronic casings, EMI shielding, and capacitor foils. Its high electrical and thermal conductivity ensures efficient heat dissipation and protection for sensitive electronic components, preventing overheating and ensuring stable operation.

- Packaging Industry: From beverage cans and food container111s to pharmaceutical foils, aluminum provides an excellent barrier against light, moisture, and oxygen, extending shelf life and ensuring product integrity. Its recyclability is also a major environmental advantage.

Key Technical Advantages

The inherent properties of aluminum, when processed into sheets, offer distinct technical advantages that drive its widespread adoption in demanding B2B applications.

- Exceptional Strength-to-Weight Ratio: Aluminum is approximately one-third the density of steel, yet certain alloys can achieve comparable or even superior strength. This translates to significant weight savings, crucial for mobility applications, reducing energy consumption and increasing payload capacity.

- Superior Corrosion Resistance: Aluminum naturally forms a tenacious, protective oxide layer when exposed to air. This passivation layer acts as a barrier against corrosion, especially in various atmospheric conditions and corrosive environments, making it ideal for outdoor and marine applications. Anodizing can further enhance this protection.

- Excellent Thermal and Electrical Conductivity: Aluminum boasts high thermal conductivity, making it an excellent material for heat sinks, heat exchangers, and other thermal management components. Its good electrical conductivity is advantageous for electrical busbars and transmission lines, offering efficient energy transfer.

- High Formability and Weldability: Aluminum sheets can be easily formed, bent, drawn, and machined into complex shapes using standard manufacturing processes. Many alloys are also readily weldable, allowing for intricate fabrication and assembly, though specific techniques are often required.

- 100% Recyclability: Aluminum is one of the most recyclable materials on the planet, retaining its original properties indefinitely without degradation. Recycling aluminum requires significantly less energy (up to 95%) compared to primary production, underscoring its environmental and economic sustainability.

- Non-Magnetic Properties: Aluminum is non-magnetic, which is a critical advantage in applications sensitive to magnetic fields, such as electronics, medical equipment (e.g., MRI machines), and certain scientific instruments.

Vendor Comparison for Aluminum Sheet Supply

Selecting the right supplier for Aluminum Sheet is a critical decision that impacts project timelines, quality, and overall cost-efficiency. While many suppliers offer standard products, differentiation lies in quality assurance, customization capabilities, and customer support.

Table 3: Comparative Analysis of Aluminum Sheet Suppliers (Illustrative)

| Criteria | Pulongte (Example) | Vendor B (Generic) | Vendor C (Generic) |

|---|---|---|---|

| Quality Certifications | ISO 9001:2015, ASTM, EN, SGS Tested | ISO 9001:2008 | Basic Certifications |

| Customization Capabilities | Extensive: Custom alloys, tempers, sizes, surface finishes, cutting (laser, waterjet) | Limited to standard sizes and common alloys | Minimal, bulk standard orders |

| Typical Lead Time (Standard) | 3-5 business days (ex-stock), 2-4 weeks (production) | 5-7 business days (ex-stock), 3-6 weeks (production) | 7-10 business days (ex-stock), 4-8 weeks (production) |

| Price Competitiveness | Highly competitive for quality & customization | Moderate, varies with volume | Low-cost focus, potentially lower quality |

| Technical Support & Expertise | Dedicated engineering team, material science experts, pre/post-sales support | Standard support, limited technical depth | Basic customer service |

| Global Reach & Logistics | Established global logistics, reliable international shipping | Regional focus with some international shipping | Primarily domestic or limited export |

Customized Solutions for Specific Project Requirements

Recognizing that off-the-shelf solutions may not always meet the precise demands of advanced engineering projects, we specialize in providing highly customized Aluminum Sheet solutions. Our approach involves close collaboration with clients to deliver materials perfectly tailored to their unique specifications and performance criteria.

- Tailored Alloy Selection: Beyond standard 1xxx, 3xxx, 5xxx, and 6xxx series, we assist in selecting or developing specific alloy compositions optimized for characteristics such as enhanced formability, superior strength, improved weldability, or specific corrosion resistance for highly specialized environments.

- Optimized Temper Conditions: Whether an ultra-soft 'O' temper for deep drawing, specific 'H' series tempers for work-hardened requirements, or 'T' series tempers for maximum strength post-heat treatment, we precisely control the thermal processing to achieve the exact mechanical properties needed.

- Precision Dimensions and Cutting: We offer custom thickness, width, and length dimensions, including large-format sheets and ultra-thin foils. Advanced cutting technologies such as laser cutting, waterjet cutting, and CNC machining ensure high precision and minimal material waste for complex geometries.

- Specialized Surface Finishes: From various mill finishes to brushed, polished, anodized (clear, colored, hard coat), or painted surfaces, we provide a range of aesthetic and functional finishes to meet specific design and protective requirements.

- Value-Added Services: Our customization extends to protective film application, specialized packaging for fragile or high-value shipments, and precise tolerance controls for demanding applications like aerospace or semiconductor manufacturing.

Our team of metallurgists and engineers works directly with your design and procurement teams to understand project scope, performance metrics, and environmental conditions, ensuring that every sheet delivered is fit-for-purpose and exceeds expectations.

Real-World Application Case Studies

Our commitment to quality and technical expertise is best illustrated through successful applications of our Aluminum Sheet in demanding industrial projects.

Case Study 1: Advanced Electric Vehicle Battery Enclosure

Client: Leading Global EV Manufacturer

Challenge: The client required a battery enclosure material that could significantly reduce vehicle weight while offering superior thermal management, high structural integrity to protect sensitive battery cells, and excellent resistance to road salt corrosion.

Solution: We supplied customized 6061-T6 Aluminum Sheet with specific dimensions and a proprietary surface treatment. The 6061-T6 alloy was chosen for its excellent strength-to-weight ratio and ability to be extruded and welded into complex, rigid structures. The surface treatment provided enhanced corrosion protection against road contaminants.

Result: The implementation of our specialized aluminum sheets led to a 25% reduction in battery enclosure weight compared to previous designs, contributing to a 5% increase in vehicle range. The high thermal conductivity of the aluminum also improved heat dissipation from the battery pack, extending battery life and enhancing safety. Client feedback highlighted the material's consistent quality and ease of fabrication.

Case Study 2: High-Performance Industrial HVAC Heat Exchanger

Client: Industrial HVAC System Integrator

Challenge: The client needed a material for a large-scale industrial heat exchanger that could efficiently transfer heat, withstand continuous operational temperatures, and resist corrosion in a humid, mildly acidic environment, all while minimizing overall unit weight.

Solution: We provided custom-rolled 3003-H14 Aluminum Sheet, known for its excellent thermal conductivity and good corrosion resistance, particularly against fresh water and mild chemical solutions. The H14 temper offered the required strength and formability for the intricate fin and tube designs of the heat exchanger.

Result: The 3003-H14 aluminum sheets significantly improved the heat exchanger's efficiency by 18% compared to previous designs, leading to substantial energy savings for the end-user. The material's inherent corrosion resistance also extended the service life of the units, reducing maintenance costs. The client praised the material's consistent gauge and surface quality, which facilitated smooth production.

Frequently Asked Questions (FAQ)

Q1: What are the primary advantages of Aluminum Sheet over steel in industrial applications?

A: Aluminum sheet offers a significantly higher strength-to-weight ratio, superior corrosion resistance (especially in marine environments due to its passive oxide layer), excellent thermal and electrical conductivity, and is 100% recyclable, leading to energy savings and reduced environmental impact. While steel is generally stronger, aluminum's specific strength can be comparable or better for many applications, making it ideal for lightweighting.

Q2: Can aluminum sheets be welded, and what methods are recommended?

A: Yes, most aluminum sheets can be welded, though specific techniques are required due to aluminum's high thermal conductivity and propensity to form an oxide layer. Common welding methods include Gas Metal Arc Welding (GMAW/MIG) and Gas Tungsten Arc Welding (GTAW/TIG). Proper filler metal selection, surface preparation (oxide removal), and shielding gas are crucial for strong, defect-free welds.

Q3: How does Pulongte ensure the quality of its aluminum sheet products?

A: Pulongte adheres to a stringent quality management system certified to ISO 9001:2015. Our process includes rigorous testing at every stage, from raw material inspection to final product verification. This involves chemical composition analysis, mechanical property testing (tensile, yield, elongation, hardness), dimensional accuracy checks, and surface quality inspections, all in accordance with international standards like ASTM B209 and EN 485.

Q4: What surface finishes are available for aluminum sheets?

A: We offer a variety of surface finishes to suit different functional and aesthetic requirements. These include standard mill finish, brushed, polished, anodized (clear, colored, or hard coat for increased wear resistance), and pre-painted or powder-coated options. The choice of finish depends on the application's demands for corrosion resistance, appearance, and durability.

Lead Time & Fulfillment Details

Understanding the logistics of material supply is critical for project planning. Our lead times for Aluminum Sheet are structured to support both urgent and long-term procurement needs:

- Standard Stock Items: For commonly requested alloys, tempers, and dimensions, we maintain a robust inventory, allowing for dispatch within 3-5 business days upon order confirmation.

- Custom Orders & Production Runs: For specialized alloys, unique dimensions, or large-volume production, typical lead times range from 2-4 weeks. This duration accounts for specific casting, rolling, heat treatment, and finishing processes tailored to your requirements.

- Express Services: Expedited manufacturing and shipping options are available for critical deadlines, subject to material availability and production scheduling.

We utilize a global network of logistics partners to ensure timely and secure delivery to your facility, whether domestic or international. All shipments are meticulously packaged to prevent damage during transit, with options for customized crating and protective wrapping as needed.

Warranty Commitments

Pulongte stands behind the quality and integrity of every Aluminum Sheet product we supply. Our warranty commitments reflect our confidence in our manufacturing processes and adherence to international quality standards:

- Product Quality Guarantee: All products are guaranteed to meet or exceed the specified alloy composition, mechanical properties, and dimensional tolerances as per relevant ASTM, EN, or JIS standards and your agreed-upon specifications.

- Defect-Free Assurance: We warrant our materials to be free from manufacturing defects in workmanship and material under normal use and service.

- Claims Process: In the unlikely event of a quality issue, our dedicated support team will promptly investigate and resolve the claim in accordance with our transparent warranty policy. This includes material replacement or credit, subject to a thorough technical evaluation.

Our ISO 9001 certified quality management system underpins all our production and supply activities, ensuring traceability and consistent performance for every batch of material delivered.

Dedicated Customer Support & Technical Assistance

At Pulongte, our partnership extends beyond product delivery. We provide comprehensive customer support and expert technical assistance to ensure your projects succeed:

- Pre-Sales Consultation: Our experienced sales and technical teams are available to discuss your project requirements, recommend optimal aluminum alloys and tempers, and assist with specification development.

- Technical Expertise: Access to our metallurgists and engineers for in-depth technical queries, material performance analysis, and problem-solving. We offer guidance on fabrication techniques, surface treatments, and application-specific challenges.

- Dedicated Account Management: Each client is assigned a dedicated account manager, ensuring a single point of contact for streamlined communication and personalized service.

- After-Sales Support: Our commitment continues after delivery, with support for any post-purchase inquiries, feedback, or resolution of potential issues.

Contact Information: For inquiries, technical support, or to request a quote, please visit our website at www.pulongte.com or reach out through our dedicated contact channels. We are committed to being your reliable partner for all your aluminum material needs.

Authoritative References

- ASTM International. Standard Specification for Aluminum and Aluminum-Alloy Sheet and Plate. ASTM B209/B209M.

- European Standard. Aluminium and aluminium alloys - Sheet, strip and plate. EN 485.

- The Aluminum Association. Aluminum Design Manual.

- ASM Handbook, Volume 2: Properties and Selection: Nonferrous Alloys and Special-Purpose Materials. ASM International.

- International Organization for Standardization. Quality management systems — Requirements. ISO 9001:2015.

-

Comprehensive Guide to White PVC Material: Benefits, Applications & Innovations

NewsNov.24,2025

-

Flat Hard Plastic PP Flexible Strips: Durable, Flexible, and Sustainable Solutions for Modern Industry

NewsNov.24,2025

-

Understanding Soft PVC Slip Cover Tuck Grip – Global Uses & Benefits

NewsNov.23,2025

-

Discover the Practical Benefits and Global Use of Square Plastic Tubes

NewsNov.23,2025

-

Understanding Led Lampshade Diffuser PC Covers – Benefits, Trends & Buying Guide

NewsNov.22,2025

-

Durable, Cost-Effective PVC Rectangular Grey Tube for Frame Solutions | Pulongte

NewsNov.22,2025