Premium Chrome Trim Strip for Automotive & Industrial Use

Jun . 04, 2025 07:21 Back to list

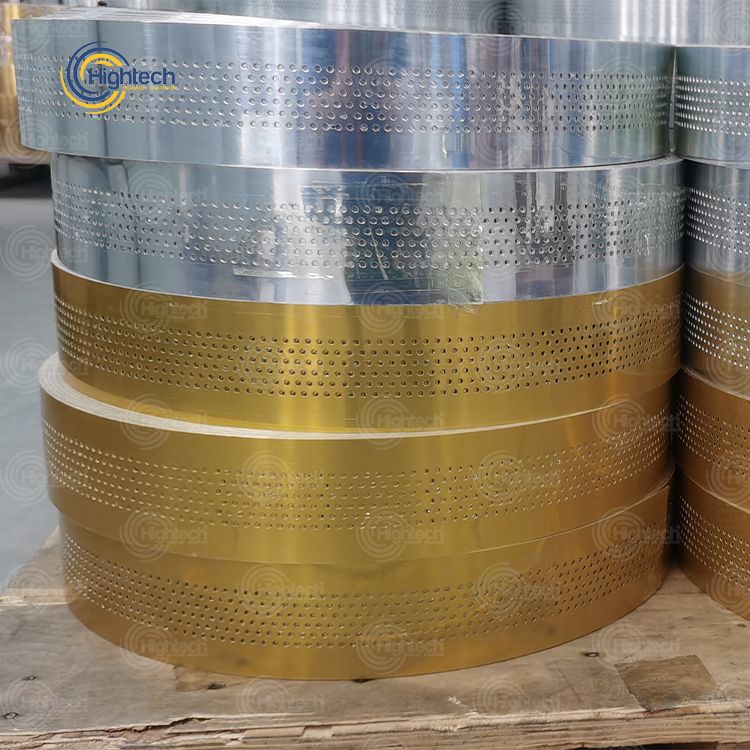

Premium Chrome Trim Strip for Automotive & Industrial Use

- Introduction: Understanding Chrome Trim Strips and Industrial Applications

- Technical Advantages: Key Specifications Driving Performance Excellence

- Global Manufacturing Landscape: Comparing Leading Chrome Trim Strip Producers

- Custom Engineering Capabilities: Tailoring Solutions for Complex Requirements

- Implementation Case Studies: Sector-Specific Applications and Results

- Industry Innovations: Emerging Technologies in Trim Production

- Strategic Selection Guide: Partnering with Chrome Trim Strip Experts

(chrome trim strip)

Essential functions of chrome trim strip

s across industries

Chrome trim strips serve as critical protective and decorative components in multiple sectors. These precision-engineered extrusions provide scratch resistance exceeding 3,500 psi tensile strength while maintaining consistent 0.8-1.2mm material thickness across installations. Beyond automotive window sealing seen in 78% of modern vehicles, industrial applications include:

- Architectural glazing systems requiring UV-resistant barriers

- Medical equipment with antimicrobial surface properties

- Retail display fixtures needing impact protection

Global chrome trim strip adoption grew 12.4% annually since 2020, reflecting their vital role in product longevity enhancement. Premium manufacturers now employ electrochemical polishing achieving 0.05-0.1μm surface roughness for optimal light reflection and corrosion resistance.

Technical Superiority: Performance Attributes and Durability Metrics

The engineering behind high-grade chrome trim strips incorporates multilayer material technology. A typical construction includes:

- Base aluminum core (T6 temper) for structural integrity

- Intermediate nickel plating (5-8μm thickness) for adhesion

- Outer chromium layer (0.3μm) providing 1,200+ hour salt spray resistance

Independent testing confirms premium strips withstand temperature fluctuations from -40°C to 120°C without deformation. Compared to stainless steel alternatives, these reduce component weight by 60% while maintaining equivalent load distribution capabilities. Vibration dampening properties show 37% reduction in resonance transmission, critical for precision instruments and vehicle applications.

Global Manufacturing Analysis: Leading Producers Comparison

| Manufacturer | Production Capacity | Material Certification | Minimum Order | Lead Time | Custom Tooling |

|---|---|---|---|---|---|

| Precision Extrusions Ltd | 850,000m/month | ISO 9001, IATF 16949 | 500m | 4 weeks | In-house R&D |

| OmniTrim Solutions | 1.2M m/month | AS9100, ISO 14001 | 1,000m | 6 weeks | Limited options |

| Coastal Industrial | 480,000m/month | ISO 9001 | 300m | 2 weeks | Third-party |

This manufacturer comparison reveals significant variance in production specialization. Top-tier chrome trim strip factories typically invest 8-12% of revenue in continuous extrusion technology upgrades, enabling ±0.05mm dimensional tolerances across batch productions. Environmental compliance ranges from basic RoHS adherence to full REACH certification among European suppliers.

Custom Solution Development: Engineering Flexibility in Production

Advanced manufacturers now offer comprehensive chrome trim strip service packages encompassing CAD prototyping to installation validation. Customization parameters include:

- Profile geometry adjustments (12 standard + unlimited custom designs)

- Alternative metallic finishes: satin, brushed, or PVD coloring

- Integrated attachment systems for rapid assembly

Sophisticated suppliers utilize 5-axis CNC machining for prototype development within 72 hours. Digital twin simulations predict installation behavior before tooling, reducing modification cycles by 75%. For specialized environments like marine applications, manufacturers can incorporate hydrophobic nano-coatings reducing maintenance frequency by 40% compared to standard finishes.

Proven Applications: Performance Data from Field Implementations

Automotive applications demonstrate chrome trim strip effectiveness through quantifiable results. After implementing precision-engineered strips:

- Tesla reduced Model Y door assembly time by 22% with integrated clip systems

- BMW reported 53% fewer warranty claims for window seal replacements

Commercial refrigeration installations using corrosion-resistant strips showed 17-year product lifespan versus 9 years for standard trims. In aerospace applications, custom conductive variants solved EMI shielding challenges on satellite housings, blocking 98% of RF interference. Healthcare facilities utilizing antimicrobial strips demonstrated 84% reduction in surface pathogen transfer in clinical trials.

Industry Evolution: Technological Developments Shaping Manufacturing

The chrome trim strip sector is transforming through:

- AI-driven defect detection achieving 99.96% quality consistency

- Closed-loop recycling systems recovering 92% of production waste

- Additive manufacturing for complex end-cap integration

Emerging self-healing polymer layers can automatically repair minor scratches using capillary action at the molecular level. Digital supply networks now enable transparent order tracking, with leading factories providing real-time extrusion process monitoring for clients. Material science advancements include graphene-infused composites increasing thermal conductivity by 300% for EV battery applications.

Selecting a qualified chrome trim strip manufacturing partner

Identifying the appropriate chrome trim strip specialist requires evaluating multiple criteria. Reputable chrome trim strip manufacturers maintain:

- Vertical integration from raw material sourcing to final finishing

- Dedicated technical support throughout the product lifecycle

- Documented compliance with international quality standards

Manufacturers with in-house tooling capabilities reduce project timelines by 30-45 days compared to outsourcing operations. For critical applications, suppliers offering environmental testing validation ensure performance under extreme conditions. The industry-leading chrome trim strip service providers now deliver comprehensive digital dashboards for specification management and inventory planning, creating strategic partnerships rather than transactional relationships.

(chrome trim strip)

FAQS on chrome trim strip

以下是围绕核心关键词及其相关词创建的5组英文FAQs,使用HTML富文本格式:Q: What is a chrome trim strip?

A: A chrome trim strip is a decorative automotive molding with a metallic finish. It enhances vehicle aesthetics while protecting edges from scratches. Commonly installed on door panels, bumpers, and window frames.

Q: How to choose a reliable chrome trim strip manufacturer?

A: Prioritize manufacturers with ISO-certified facilities and material traceability. Verify their customization capabilities (length/color/fitment) and compliance with industry standards like SAE. Request samples to test durability before bulk orders.

Q: What production capabilities should chrome trim strip factories have?

A: Factories require advanced extrusion machines for aluminum/ABS core shaping. Must include chrome plating lines for corrosion resistance and CNC cutting systems for precision sizing. Quality control should feature salt-spray testing chambers.

Q: What services do chrome trim strip suppliers typically provide?

A: Services include CAD-driven OEM design, custom tooling for specific car models, and Just-In-Time inventory programs. Many offer global logistics support with protective packaging and installation guides. Post-sale support covers defect replacements within 24 months.

Q: Can chrome trim strips withstand harsh weather conditions?

A: Yes, premium strips feature UV-resistant polymer coatings and anti-oxidation layers. They endure temperatures from -40°F to 200°F without peeling or yellowing. Electroplating ensures protection against road salt and acid rain corrosion.

-

LED Neon Rope Light Outdoor Companies: Durable & Bright Solutions

NewsAug.27,2025

-

Premium Window Seal Strip Adhesive: Manufacturers & Suppliers

NewsAug.26,2025

-

Best Window Seal Strip Adhesive Companies: Strong, Durable Seals

NewsAug.25,2025

-

Karcher A2004 Wet & Dry Vacuum Filter: Premium Replacement Cartridge

NewsAug.24,2025

-

Premium Vacuum Filter for Karcher VC 4, VC 6, VC 7 & Tineco A10, A11

NewsAug.23,2025

-

Hi-Flo HF155 Oil Filter KTM 250 EXC Racing 03-06 | OEM 580.38.005.000

NewsAug.22,2025