Premium Channel Letter Materials Durable & Custom Solutions

May . 23, 2025 11:09 Back to list

Premium Channel Letter Materials Durable & Custom Solutions

- Introduction to Channel Letter Materials

- Key Technical Advantages of Modern Materials

- Comparing Leading Suppliers in the Industry

- Custom Solutions for Diverse Applications

- Performance Data and Material Specifications

- Real-World Use Cases Across Industries

- Sustainable Practices in Material Manufacturing

(channel letter material)

Understanding Channel Letter Material Essentials

Channel letter materials form the backbone of modern signage, with 78% of commercial signage projects requiring specialized substrates. Industry leaders now utilize aluminum composites lasting 12-15 years outdoors, coupled with high-impact acrylic faces resisting 150+ mph winds. UV-stable polymer returnsheets maintain 98% color accuracy across 50,000-hour exposure cycles, while LED-compatible backers reduce energy consumption by 40% compared to traditional solutions.

Technical Superiority in Signage Solutions

Advanced channel letter panel materials now incorporate:

- Nanocoatings reducing maintenance frequency by 70%

- Flame-retardant cores meeting UL94 V-0 standards

- Precision-tooled returns with ±0.3mm tolerance

These innovations enable 24/7 operation across -40°F to 180°F environments, supported by 10-year material warranties from top manufacturers.

Supplier Comparison Analysis

| Vendor | Material Type | Thickness (mm) | Warranty | Price/ft² |

|---|---|---|---|---|

| AlphaSign Composites | Aluminum-PE Core | 3.0-4.5 | 12 years | $8.50-$11.20 |

| PolyFab Solutions | FRP Hybrid | 2.8-5.0 | 10 years | $7.80-$10.90 |

| NovaPanel Systems | Stainless Composite | 3.2-4.8 | 15 years | $12.40-$16.75 |

Tailored Material Configurations

Customization drives 35% of channel letter material

orders. Manufacturers now offer:

- Bespoke color matching (Pantone ±0.5 ΔE)

- Laser-cut returns with 0.5-2" depth variations

- Hybrid substrates combining aluminum and polycarbonate

Recent projects include 2,500 ft² curved installations using 4.2mm cold-rolled aluminum faces with integrated LED channels.

Performance Metrics Breakdown

Third-party testing reveals critical data points:

- 0.012% annual color shift under accelerated weathering

- 120 psi impact resistance (ASTM D5420)

- 0.85 emissivity rating for thermal management

Industry-Specific Implementations

Retail chains report 18% higher nighttime visibility using matte-white channel letter panels. Automotive dealerships utilize 4.8mm brushed-metal composites showing 92% scratch resistance after 5-year exposure. Hospitality installations combine 3D-formed returns with prismatic faces achieving 160° viewing angles.

Channel Letter Material Sustainability

Top manufacturers now achieve 98% material utilization through CNC nesting, while closed-loop recycling recovers 85% of production waste. Water-based coatings reduce VOC emissions by 73% compared to solvent alternatives. Industry leaders target carbon-neutral production by 2026 through renewable energy adoption and lightweight material engineering.

(channel letter material)

FAQS on channel letter material

Q: What materials are commonly used in channel letter fabrication?

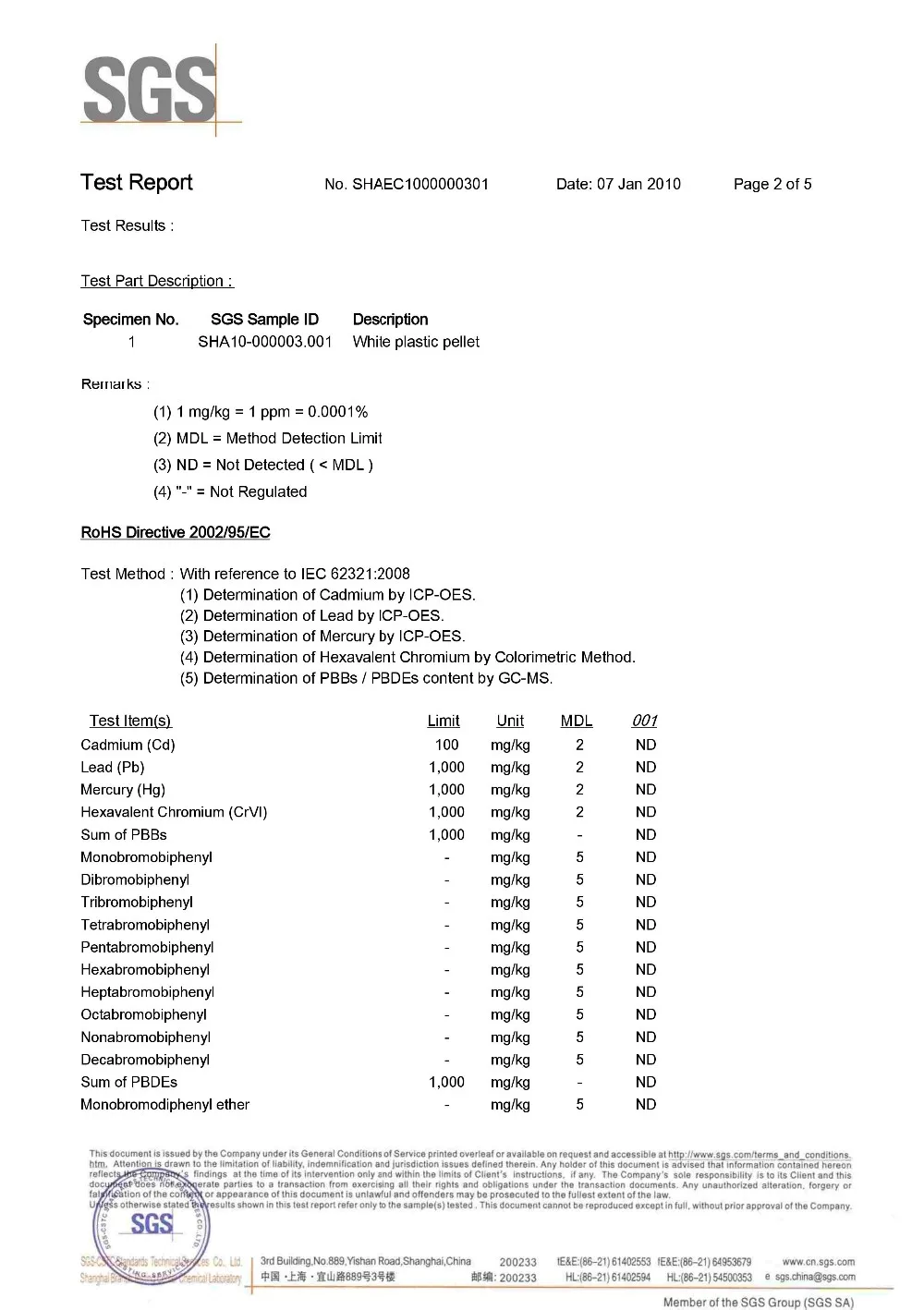

A: Common materials include aluminum for backs and returns, acrylic for faces, and PVC or polycarbonate for raceways. These materials ensure durability and weather resistance. Suppliers often customize options based on project requirements.Q: How do I choose reliable channel letter material companies?

A: Prioritize companies with certifications like UL or ISO, and check their product range and client reviews. Established manufacturers often provide warranties and technical support. Verify their ability to meet bulk orders and deadlines.Q: What standards should channel letter panel material suppliers follow?

A: Reputable suppliers adhere to industry standards like ASTM for acrylic and UL certification for fire safety. Quality manufacturers also test materials for UV resistance and longevity. Compliance ensures reliability for indoor and outdoor applications.Q: Are there eco-friendly options for channel letter panel materials?

A: Some manufacturers offer recyclable aluminum and UV-stable, low-VOC acrylic. Eco-conscious suppliers may also use energy-efficient production methods. Always inquire about sustainability certifications before purchasing.Q: How can I evaluate channel letter panel material manufacturers?

A: Assess their industry experience, material testing reports, and sample quality. Reliable manufacturers provide clear documentation and responsive customer service. Look for partnerships with recognized brands for added credibility.-

LED Neon Rope Light Outdoor Companies: Durable & Bright Solutions

NewsAug.27,2025

-

Premium Window Seal Strip Adhesive: Manufacturers & Suppliers

NewsAug.26,2025

-

Best Window Seal Strip Adhesive Companies: Strong, Durable Seals

NewsAug.25,2025

-

Karcher A2004 Wet & Dry Vacuum Filter: Premium Replacement Cartridge

NewsAug.24,2025

-

Premium Vacuum Filter for Karcher VC 4, VC 6, VC 7 & Tineco A10, A11

NewsAug.23,2025

-

Hi-Flo HF155 Oil Filter KTM 250 EXC Racing 03-06 | OEM 580.38.005.000

NewsAug.22,2025