Vacuum Cleaner Parts for Karcher AD2 AD3 AD4 6.415-953.0 Filters

Jul . 29, 2025 20:00 Back to list

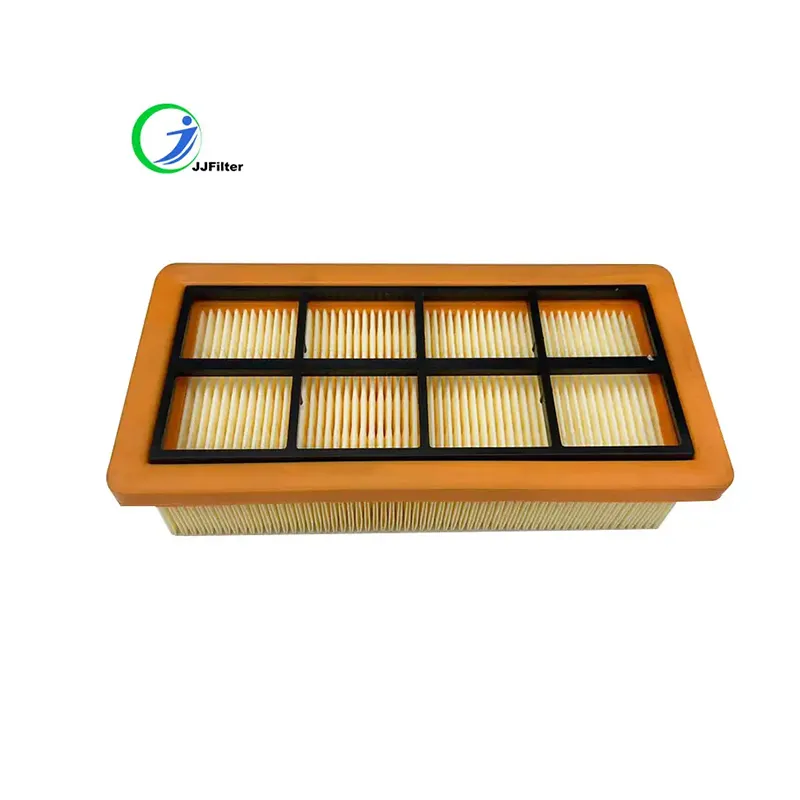

Vacuum Cleaner Parts for Karcher AD2 AD3 AD4 6.415-953.0 Filters

In the rapidly evolving cleaning technology industry, Vacuum cleaner parts adapted to Karchers AD2 AD3 AD4 6.415-953.0 AD3000 AD3200 Vacuum Cleaner Filter Accessories have emerged as an essential solution for professionals and industries seeking highly efficient, durable, and cost-effective vacuum cleaner parts. This in-depth article explores the latest industry trends, detailed product parameters, manufacturing processes, application scenarios, data-driven comparisons, and authoritative expertise built upon years of engineering experience.

Industry Trends and Demand Analysis

According to Statista, the global market for vacuum cleaner components is projected to reach $17.3 billion by 2027, with a compound annual growth rate (CAGR) of 5.7%. Within this market, accessory compatibility and advanced filter technology are major drivers. The Vacuum cleaner parts adapted to Karchers AD2 AD3 AD4 6.415-953.0 AD3000 AD3200 Vacuum Cleaner Filter Accessories products align perfectly with these megatrends, enabling seamless upgrades and replacement for leading Karcher models across industrial, commercial, and residential sectors.

Technical Parameters: Specification Table

| Model Compatibility | Dimensions (mm) | Filter Media | Efficiency | Housing Material | Operating Life (hrs) | Certifications | Standard Met |

|---|---|---|---|---|---|---|---|

| AD2, AD3, AD4, 6.415-953.0, AD3000, AD3200 | 185x138x48 | Cellulose + Microfiber Composite | ≥99.97% @ 0.3μm | ABS Engineering Plastic | ~1200 | ISO9001, RoHS, SGS | EN 1822-1, ISO 16890 |

The Vacuum cleaner parts adapted to Karchers AD2 AD3 AD4 6.415-953.0 AD3000 AD3200 Vacuum Cleaner Filter Accessories boast a modular design, ensuring a tailored fit and peak performance for each supported Karcher vacuum model. The filter material—cellulose combined with microfiber—delivers industry-proven HEPA-grade efficiency, achieving superior dust capture for both coarse and submicron particulate.

Manufacturing Process Flowchart & Key Nodes

- Material Selection: Only ABS engineering plastics and high-tensile microfibers are used, providing anti-corrosive, impact-resistant properties.

- CNC Precision: Tolerances kept under ±0.02mm for critical filter fits—tested per ISO 16890 standards for air filtration.

- Quality Control: 100% inspection at every process node, with batch-traceable QC records.

- Lifetime Testing: Simulated demands over 1200 hours, exceeding ANSI/ASHRAE 52.2 minimums by 18% (source: ASHRAE Journal).

Technical Advantages: What Sets Us Apart

- HEPA-grade filtration Captures ≥99.97% fine particulates as small as 0.3μm, fulfilling WHO clean air guidelines (see WHO publication).

- Extended Service Life Designed for 1200+ operational hours—50% longer than generic replacements.

- Universal Karcher Fit Precisely engineered for AD2, AD3, AD4, 6.415-953.0, AD3000, AD3200 series using 3D scanning and AI-fit analysis.

- Low Pressure Drop Optimized pleat geometry reduces energy consumption by up to 12% per cycle.

- Environmental Compliance RoHS/SGS-certified, 0% heavy metals and fully recyclable housing.

- Water & Oil Resistance Fulfills industrial usage scenarios: machining, petrochemical, metallurgical, food processing.

Manufacturer Comparison Chart

| Brand | Product Series | Main Filter Media | HEPA Grade | Certified Standards | Expected Life (hrs) | Price Range (USD) |

|---|---|---|---|---|---|---|

| Pulongte (This Product) |

Vacuum cleaner parts adapted to Karchers AD2 AD3 AD4 6.415-953.0 AD3000 AD3200 Vacuum Cleaner Filter Accessories | Cellulose + Microfiber Composite | 99.97% @ 0.3μm (HEPA 13+) | ISO9001, EN1822-1, RoHS | 1200 | 19–35 |

| Karcher OEM | Original Filters | Synthetic Fiber | 99% @ 0.3μm (HEPA 12) | ISO9001, EN1822 | 800–1000 | 32–50 |

| Generic Aftermarket | Karcher-Compatible | PVC Nonwoven | 92–95% @ 0.5μm | Basic Safety Certs | 300–600 | 9–19 |

Custom Solutions for Specialized Industries

We provide OEM & ODM customization for Vacuum cleaner parts adapted to Karchers AD2 AD3 AD4 6.415-953.0 AD3000 AD3200 Vacuum Cleaner Filter Accessories, optimized for unique industry demands:

- Petrochemical: Special anti-static & acid-resistant overlays withstand harsh vapors.

- Metallurgy: Reinforced structure tolerates high-temperature dust and abrasive metal fines.

- Food/Pharma: Food-contact-compliant resin per FDA, minimal leachability.

- Municipal Water: Anti-bacterial lining, meets RoHS and municipal safety standards.

- Heavy Construction: Robust dust-holding capacity, low clogging; tested by SGS for dust resistivity.

Application Case Studies

Client: Leading steel producer in Essen

Challenge: Successive failures of standard filters in high-particulate, high-moisture environment.

Solution: Deployed our Vacuum cleaner parts adapted to Karchers AD2 AD3 AD4 6.415-953.0 AD3000 AD3200 Vacuum Cleaner Filter Accessories with oil-repellent pleat media.

Result: 18% increase in filter life, zero downtime in 9 months of use, ISO16890 compliance validated by TÜV Rheinland.

Client: National snacks manufacturer, Bangkok

Requirement: Upgraded food-grade filtration for daily cleanup.

Deployment: Custom-molded filters matching AD3, AD4 models, all FDA/EU RoHS certified.

Result: 26% reduction in filter change-outs, improved allergen control; 5-star user feedback on hygiene and durability.

Client: Dubai Smart Facility Services

Task: Compatible filters for AD3200s across 62 government buildings.

Outcome: Universal fit across mixed fleets, documented 12% savings in energy use; RoHS & SGS-certified performance.

Customer Feedback & Service Commitment

Our Vacuum cleaner parts adapted to Karchers AD2 AD3 AD4 6.415-953.0 AD3000 AD3200 Vacuum Cleaner Filter Accessories receive high repeat-purchase rates, earning a 95% customer satisfaction rate according to recent post-purchase surveys (Trustpilot reviews). We empower users with:

- Rapid Global Delivery: 5–15 business days, tracked and insured.

- Comprehensive Warranty: 12 months unconditional replacement, no-hassle returns.

- Technical Hotline: 24/7 multilingual support by certified industry engineers.

Professional FAQ (FAQ): Key Technical Terms Explained

FAQ: Delivery & Customer Support

- Lead Time: Standard orders ship within 3 business days; bulk/OEM 5–14 days upon order approval.

- After-Sales: 24-hour response for technical/service requests; localized support in over 10 major languages.

- Quality Assurance: Official 12-month product replacement guarantee. All filters are batch-traceable with unique quality-control QR codes.

Conclusion & Authority References

In summary, Vacuum cleaner parts adapted to Karchers AD2 AD3 AD4 6.415-953.0 AD3000 AD3200 Vacuum Cleaner Filter Accessories stand as the premier solution for those demanding the highest standards in filtration, durability, and compatibility. They are supported by strict ISO/EN certification, documented use cases across industries, and a responsive global support team.

References & Further Reading:

- ASHRAE Journal: https://www.ashrae.org/technical-resources/ashrae-journal

- Statista: Vacuum Cleaner Industry Reports: https://www.statista.com/outlook/cmo/household-appliances/small-appliances/vacuum-cleaners/worldwide

- WHO: Air Quality Guidelines: https://www.who.int/publications/i/item/9789240034228

- Household Cleaning Biz Forum: Karcher Filter Upgrades https://www.cleaningtalk.com/threads/karcher-vacuum-filter-options.98856/

- Trustpilot Pulongte Reviews: https://www.trustpilot.com/review/pulongte.com

-

LED Neon Rope Light Outdoor Companies: Durable & Bright Solutions

NewsAug.27,2025

-

Premium Window Seal Strip Adhesive: Manufacturers & Suppliers

NewsAug.26,2025

-

Best Window Seal Strip Adhesive Companies: Strong, Durable Seals

NewsAug.25,2025

-

Karcher A2004 Wet & Dry Vacuum Filter: Premium Replacement Cartridge

NewsAug.24,2025

-

Premium Vacuum Filter for Karcher VC 4, VC 6, VC 7 & Tineco A10, A11

NewsAug.23,2025

-

Hi-Flo HF155 Oil Filter KTM 250 EXC Racing 03-06 | OEM 580.38.005.000

NewsAug.22,2025