Top Window Seal Strip Adhesive Companies: Durable & Efficient

Sep . 01, 2025 02:00 Back to list

Top Window Seal Strip Adhesive Companies: Durable & Efficient

The Critical Role of Industrial Window Seal Strip Adhesive Manufacturers

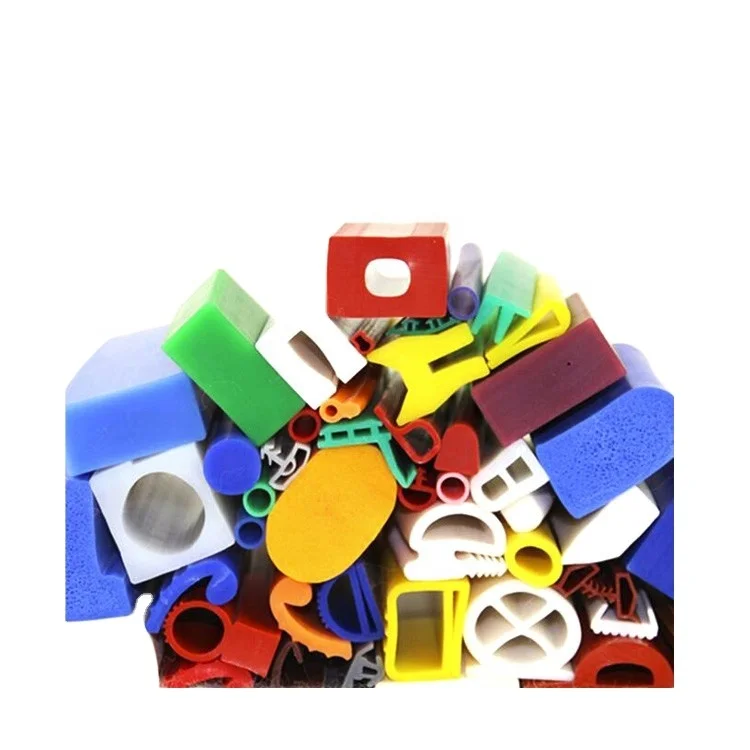

In diverse industrial sectors, the integrity and performance of sealing solutions are paramount. From maintaining thermal efficiency in high-temperature ovens to ensuring environmental isolation in sensitive electronic enclosures, the demand for robust, reliable sealing materials is constant. This is where specialized window seal strip adhesive companies play a pivotal role. These entities are at the forefront of designing, manufacturing, and supplying advanced sealing solutions, often incorporating high-performance materials like silicone rubber, to meet stringent industry requirements. This comprehensive overview delves into the landscape of such companies, examining industry trends, technical specifications, application versatility, and the critical factors that define their excellence.

Industry Trends and Market Dynamics for Sealing Solutions

The market for industrial sealing solutions is characterized by continuous innovation, driven by evolving regulatory standards, demand for energy efficiency, and advancements in material science. Key trends influencing the operations of a typical window seal strip adhesive company include:

- Emphasis on High-Performance Materials: There's a growing shift towards materials like silicone rubber, which offers superior resistance to extreme temperatures, UV radiation, ozone, and various chemicals compared to conventional elastomers. This is particularly crucial for applications demanding long service life under harsh conditions.

- Customization and Specialty Profiles: Standard off-the-shelf solutions are often insufficient. Clients increasingly require custom-engineered profiles, specific durometer hardness, and tailored adhesive backing to ensure optimal fit and performance in their unique applications. This necessitates adaptable window seal strip adhesive manufacturers.

- Sustainability and Environmental Compliance: With increasing global awareness, manufacturers are under pressure to develop environmentally friendly products, including those that are RoHS, REACH, and FDA compliant where applicable, while minimizing waste in production.

- Smart Manufacturing and Automation: Adoption of advanced manufacturing techniques, including robotics and real-time quality control, enhances precision, reduces defects, and improves production efficiency, positioning leading window seal strip adhesive factories at the cutting edge.

- Global Supply Chain Resilience: Geopolitical shifts and global events highlight the importance of diversified and resilient supply chains. Reputable window seal strip adhesive exporters are building robust networks to ensure consistent material sourcing and timely delivery.

Technical Specifications and Material Science

The core of any high-performance seal lies in its material composition and meticulous engineering. For products such as the "High temperature resistant E P shaped silicone rubber sealing strip rubber gasket for oven door," the choice of silicone rubber is critical. Silicone elastomers are renowned for their exceptional thermal stability, maintaining flexibility and sealing properties across a wide temperature range, typically from -60°C to +250°C, and even higher for specific formulations.

Key Material Properties of Silicone Rubber:

- Temperature Resistance: Outstanding resistance to both extreme heat and cold, crucial for oven doors and HVAC systems.

- Chemical Inertness: Resistance to a wide array of chemicals, oils, and solvents, ensuring longevity in diverse industrial environments.

- UV and Ozone Resistance: Excellent outdoor weathering capabilities, preventing degradation from environmental exposure.

- Compression Set Resistance: The ability to return to its original shape after prolonged compression, vital for maintaining a consistent seal over time.

- Electrical Insulation Properties: Useful in electronic enclosures and equipment.

- Bio-compatibility: Certain grades are suitable for food-contact and medical applications (e.g., FDA approved).

Typical Product Specifications (Example: E/P Shaped Silicone Seal Strip):

| Parameter | Typical Value / Range | Testing Standard |

|---|---|---|

| Material | High-Grade Silicone Rubber (VMQ) | ASTM D2000, ISO 1629 |

| Hardness (Durometer A) | 40-70 Shore A | ASTM D2240 |

| Tensile Strength | > 5.0 MPa | ASTM D412 |

| Elongation at Break | > 200% | ASTM D412 |

| Temperature Range | -60°C to +250°C (continuous) | ASTM D2000 |

| Compression Set (22h @ 175°C) | < 20% | ASTM D395 Method B |

| Adhesive Type (Optional) | High-temperature acrylic/silicone PSA | Manufacturer Specific |

Manufacturing Process Flow for Silicone Seal Strips

The production of high-quality silicone seal strips by window seal strip adhesive companies involves a series of precision-controlled steps, ensuring material integrity and dimensional accuracy. The typical process includes:

Schematic Process Steps:

- Material Preparation (Compounding): Raw silicone polymers are mixed with various additives such as curing agents (peroxides), reinforcing fillers (silica), pigments, and heat stabilizers. This compounding is critical to achieve desired physical properties (hardness, tensile strength, temperature resistance).

- Extrusion: The compounded silicone material is fed into an extruder. Under heat and pressure, the silicone is pushed through a die, which is precisely shaped to form the desired profile (e.g., E-shape, P-shape, D-shape). This is a continuous process.

- Curing (Vulcanization): The extruded profile is then subjected to heat in an oven (often a hot-air vulcanization tunnel or steam vulcanization) to initiate cross-linking of the polymer chains. This process transforms the soft, pliable silicone into a durable, elastic rubber.

- Cooling & Sizing: After curing, the strip is cooled and then precisely cut to specified lengths. In-line measurement systems ensure dimensional consistency.

- Adhesive Application (Optional): If an adhesive backing is required, a high-temperature resistant pressure-sensitive adhesive (PSA) is applied to one side of the cured silicone strip. This often involves a lamination process with a release liner.

- Post-Curing (Optional): For specific high-performance applications, especially those requiring FDA compliance or minimal volatile organic compounds (VOCs), a secondary, longer-duration heat treatment (post-curing) might be performed.

- Quality Control & Inspection: Each batch undergoes rigorous quality checks, including dimensional checks, durometer testing, tensile strength testing, compression set analysis, and visual inspection, against standards like ISO 9001 and specific ASTM/DIN norms.

- Packaging: Finished products are carefully packaged to prevent damage during transit, ready for distribution by window seal strip adhesive exporters.

The materials used, particularly the silicone grades, are selected based on target industry requirements. For instance, in petrochemical and metallurgy industries, seals often need enhanced chemical resistance, while in water supply & drainage, non-toxic and ozone-resistant properties are paramount. Advantages in typical application scenarios include enhanced energy saving through superior thermal insulation, and prolonged service life due to excellent corrosion resistance and material stability.

Application Scenarios and Target Industries

The versatility of high-performance silicone seal strips makes them indispensable across a multitude of industries. Window seal strip adhesive products are engineered to perform in environments where conventional rubber materials would fail.

Key Application Areas:

- Oven & Furnace Manufacturing: Essential for sealing oven doors in industrial ovens, commercial baking ovens, and high-temperature processing equipment, preventing heat loss and ensuring precise temperature control.

- HVAC & Refrigeration: Used in air handling units, industrial freezers, and cold storage facilities to maintain temperature and seal against air leakage.

- Automotive & Transportation: Sealing components in engine compartments, lighting systems, and body panels where resistance to heat, oil, and environmental factors is critical.

- Electronics & Enclosures: Providing dust, moisture, and EMI/RFI shielding for sensitive electronic components and outdoor electrical enclosures.

- Medical & Pharmaceutical: Specific FDA-compliant grades are used in medical devices, sterilizers, and cleanroom equipment where hygiene and inertness are paramount.

- Food Processing Equipment: Sealing gaskets for commercial food processing machinery, complying with food-grade regulations.

- Construction & Architecture: Weather sealing for specialized window systems and structural glazing, offering long-term resilience against elements.

In these scenarios, the E or P shape profile, for example, is specifically designed to create an effective compression seal, compensating for potential gaps and irregularities, thereby optimizing insulation and protection.

Technical Advantages and Performance Metrics

The adoption of silicone-based seal strips from reputable window seal strip adhesive suppliers delivers significant technical advantages over traditional rubber gaskets, translating into tangible benefits for industrial operations.

Key Advantages:

- Superior Thermal Management: Critical for high-temperature applications, preventing heat transfer and maintaining stable internal temperatures, directly contributing to energy savings.

- Extended Service Life: Silicone's inherent resistance to aging, weathering, and chemical degradation leads to a significantly longer operational lifespan, reducing maintenance and replacement costs.

- Enhanced Sealing Integrity: Excellent compression set resistance ensures that the seal maintains its shape and effectiveness even after prolonged compression, preventing leaks and infiltration.

- Chemical & Environmental Robustness: Ability to withstand exposure to ozone, UV light, water, and various industrial chemicals without compromising performance.

- Design Flexibility: Ease of customization into complex profiles and shapes allows for precision sealing in intricate designs.

- Safety and Compliance: Many silicone compounds are non-toxic, odorless, and can be formulated to meet specific regulatory requirements (e.g., UL 94-V0 for flame retardancy, FDA for food contact).

Vendor Comparison and Selection Criteria for Window Seal Strip Adhesive Companies

Choosing the right partner among the numerous window seal strip adhesive companies, window seal strip adhesive exporters, or window seal strip adhesive factories is a strategic decision for B2B procurement. Key factors for vendor evaluation include:

- Material Expertise: A deep understanding of silicone chemistry, compounding, and the ability to recommend the optimal material for specific applications.

- Manufacturing Capabilities: State-of-the-art extrusion and curing facilities, precision tooling, and the capacity for both high-volume and custom low-volume production.

- Quality Assurance & Certifications: Adherence to international standards such as ISO 9001, and product-specific certifications (e.g., RoHS, REACH, FDA, UL).

- Customization & R&D: Ability to develop custom profiles, formulate specialty silicone compounds, and provide engineering support for unique design challenges.

- Lead Time & Logistics: Efficient order processing, reliable lead times, and robust global logistics capabilities, especially for window seal strip adhesive exporters.

- Technical Support & After-Sales Service: Availability of expert technical assistance, sample provision, and responsive customer support.

- Cost-Effectiveness: Competitive pricing without compromising on material quality or performance. Obtaining detailed window seal strip adhesive quotes is crucial for comparison.

Comparative Analysis: Standard vs. High-Performance Silicone Seals

| Feature/Parameter | Standard Silicone Seal | High-Performance Silicone Seal (e.g., for Oven Doors) |

|---|---|---|

| Temperature Range | -50°C to +200°C | -60°C to +250°C (up to +300°C for short bursts) |

| Compression Set | 25-35% @ 150°C | < 20% @ 175°C |

| Chemical Resistance | Good (limited for strong acids/bases) | Excellent (broader resistance to various industrial chemicals) |

| Service Life | Moderate (3-5 years typical) | Extended (5-10+ years, depending on application) |

| Certifications (e.g.) | ISO 9001 | ISO 9001, FDA, RoHS, UL 94-V0 |

Customized Solutions and Design Considerations

For many B2B clients, standard sealing solutions are inadequate. This is where specialized window seal strip adhesive factories excel, offering customized solutions tailored to precise application requirements. Customization often involves:

- Custom Profiles & Dimensions: Developing unique extrusion dies for specific cross-sectional shapes (e.g., intricate E, P, D, or bulb profiles) and exact dimensions to ensure a perfect fit for a specific enclosure or door.

- Material Formulations: Adjusting silicone compounds to enhance specific properties, such as higher temperature resistance, increased tear strength, improved chemical compatibility, or specific color matching.

- Adhesive Backing Options: Offering a variety of adhesive types (e.g., high-tack acrylic, silicone-based PSA) and thicknesses, alongside different release liners, to suit diverse surface types and environmental conditions.

- Assembly & Finishing: Providing value-added services such as corner vulcanization, splicing, or specific packaging for ease of integration into the client's assembly line.

- Prototyping & Testing: Collaborative engineering and rapid prototyping services to validate designs and perform application-specific testing before full-scale production.

This bespoke approach ensures optimal performance, reduces design constraints, and ultimately leads to more efficient and durable end-products for the client.

Real-world Application Case Studies

The practical impact of high-quality silicone seal strips is best illustrated through real-world applications:

Case Study 1: Industrial Bakery Oven

A leading industrial bakery faced frequent heat loss and inconsistent baking temperatures due to the degradation of their existing oven door seals, which were made from conventional EPDM rubber. The seals deteriorated rapidly under continuous exposure to 200°C, requiring replacement every 6 months. A specialized window seal strip adhesive manufacturer engineered a custom E-shaped high-temperature resistant silicone seal with a service life optimized for 250°C. Post-implementation, the bakery reported a 15% reduction in energy consumption due to improved thermal insulation, a 50% decrease in seal replacement frequency, and consistently uniform baking results, demonstrating significant operational savings and product quality improvement.

Case Study 2: Outdoor Telecommunications Enclosures

A major telecommunications provider required robust sealing for outdoor cabinets housing sensitive electronic equipment. These enclosures were exposed to extreme UV radiation, wide temperature swings (-40°C to +60°C), and heavy rainfall. Standard neoprene seals failed prematurely, leading to moisture ingress and equipment damage. A window seal strip adhesive company provided a custom P-shaped silicone gasket with enhanced UV and ozone resistance, coupled with a high-tack acrylic adhesive for secure attachment. This solution drastically reduced field maintenance calls related to seal failure, extended equipment lifespan, and ensured uninterrupted service, highlighting the long-term reliability of silicone seals in harsh outdoor environments.

Quality Assurance and Certifications

The credibility and trustworthiness of window seal strip adhesive companies are underpinned by their commitment to stringent quality assurance and adherence to international certifications. These certifications are not merely badges but reflect rigorous processes, material integrity, and consistent product performance.

Key Certifications and Standards:

- ISO 9001: Certifies a robust Quality Management System, ensuring consistent quality in design, development, production, installation, and service.

- RoHS (Restriction of Hazardous Substances): Guarantees that the product does not contain hazardous materials like lead, mercury, cadmium, etc., crucial for environmental and health safety.

- REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals): European Union regulation addressing the production and use of chemical substances and their potential impacts on human health and the environment.

- FDA (Food and Drug Administration) Compliance: For silicone materials intended for food contact or medical device applications, ensuring non-toxicity and safety.

- UL 94-V0 (Underwriters Laboratories): A flammability standard indicating that a material stops burning within 10 seconds on a vertical part and does not drip flaming particles, essential for fire safety in many industrial applications.

- ASTM & DIN Standards: Adherence to specific material testing standards (e.g., ASTM D2240 for hardness, ASTM D412 for tensile strength) validates the physical and mechanical properties of the silicone.

These benchmarks provide B2B clients with the assurance that they are procuring reliable, safe, and high-performance window seal strip adhesive products that meet the most demanding industry specifications.

Trustworthiness & Support: Your Partner in Sealing Solutions

Beyond product quality, the reliability of a supplier is defined by its commitment to customer support, transparent operations, and long-term partnership. For B2B buyers seeking window seal strip adhesive quotes, these aspects are paramount.

Frequently Asked Questions (FAQ)

- Q1: What is the typical lead time for custom silicone seal strips?

- A1: Lead times vary based on complexity and order volume. For standard profiles, production can be 2-3 weeks. Custom profiles or specific material formulations may require 4-6 weeks for tooling and initial production runs. We always provide a detailed production schedule upon order confirmation.

- Q2: Can your silicone seals withstand harsh chemical environments?

- A2: Yes, silicone rubber exhibits excellent resistance to many chemicals, including acids, bases, and solvents. However, for specific aggressive chemicals, we recommend specialized grades of silicone or fluorosilicone (FVMQ) for enhanced chemical compatibility. Please consult our technical team with your specific chemical exposure details for material recommendation.

- Q3: Do you offer samples for testing before bulk orders?

- A3: Absolutely. We understand the importance of validating product performance in your specific application. Samples of standard profiles are generally available, and for custom designs, prototypes can be produced for rigorous testing and approval before proceeding with mass production.

- Q4: What is the expected service life of your high-temperature silicone seals?

- A4: Under recommended operating conditions (within specified temperature limits and chemical exposure), our high-temperature silicone seals are designed for extended service life, typically ranging from 5 to 10+ years, significantly outperforming conventional elastomers. Actual lifespan can vary based on the specific application's severity.

Lead Time & Fulfillment

Efficient supply chain management is crucial. We maintain a streamlined manufacturing process and robust inventory of raw materials to ensure timely fulfillment. Our lead times are transparently communicated at the quotation stage, with provisions for expedited services where feasible for urgent requirements. Global logistics partnerships ensure reliable delivery to any destination, positioning us as reliable window seal strip adhesive exporters.

Warranty Commitments & After-Sales Support

Our products are backed by a comprehensive warranty, covering manufacturing defects and material integrity. Our commitment extends beyond delivery, with dedicated after-sales support to address any application queries, performance issues, or technical assistance required post-purchase. We believe in building lasting partnerships through consistent quality and unparalleled service.

Conclusion

The landscape of industrial sealing is complex, demanding precision engineering, advanced material science, and unwavering quality. Specialized window seal strip adhesive companies are not just manufacturers; they are critical partners in ensuring the operational efficiency, safety, and longevity of industrial equipment across myriad sectors. By leveraging high-performance silicone rubber and adhering to rigorous manufacturing and quality standards, these companies provide indispensable solutions that power modern industry. For B2B decision-makers and engineers, selecting a partner with proven expertise, robust capabilities, and a commitment to customer success is paramount for achieving optimal sealing performance and long-term value.

References

- American Society for Testing and Materials (ASTM) International. (Various Standards on Rubber and Rubber Products).

- International Organization for Standardization (ISO). (ISO 9001, ISO 1629).

- U.S. Food & Drug Administration (FDA). (Code of Federal Regulations, Title 21 - Food and Drugs).

- Underwriters Laboratories (UL). (UL 94 Standard for Safety of Flammability of Plastic Materials for Parts in Devices and Appliances Testing).

- European Chemicals Agency (ECHA). (REACH Regulation Guidance).

-

Comprehensive Guide to White PVC Material: Benefits, Applications & Innovations

NewsNov.24,2025

-

Flat Hard Plastic PP Flexible Strips: Durable, Flexible, and Sustainable Solutions for Modern Industry

NewsNov.24,2025

-

Understanding Soft PVC Slip Cover Tuck Grip – Global Uses & Benefits

NewsNov.23,2025

-

Discover the Practical Benefits and Global Use of Square Plastic Tubes

NewsNov.23,2025

-

Understanding Led Lampshade Diffuser PC Covers – Benefits, Trends & Buying Guide

NewsNov.22,2025

-

Durable, Cost-Effective PVC Rectangular Grey Tube for Frame Solutions | Pulongte

NewsNov.22,2025