Acrylic Heat Bender Tool-Type A-Precision&Efficiency|Hebei Pulongte

Oct . 07, 2025 03:30 Back to list

Acrylic Heat Bender Tool-Type A-Precision&Efficiency|Hebei Pulongte

The Acrylic Heat Bender Tool-Type A is a cutting-edge solution designed to streamline the process of shaping acrylic materials with unmatched precision and efficiency. Developed by Hebei Pulongte Rubber and Plastic Technology Co., Ltd., this tool exemplifies the intersection of advanced engineering and user-friendly design, making it a preferred choice for manufacturers, artisans, and DIY enthusiasts alike. In this article, we delve into the features, advantages, technical specifications, and application scenarios of the Acrylic Heat Bender Tool-Type A, while also exploring the company’s commitment to innovation and quality.

Key Features of the Acrylic Heat Bender Tool-Type A

The Acrylic Heat Bender Tool-Type A is engineered to deliver exceptional performance in acrylic shaping. Its core features include:

- Precision Heating System: The tool utilizes a high-accuracy temperature control mechanism to ensure consistent heat distribution, allowing for precise bending of acrylic sheets without warping or cracking.

- Ergonomic Design: The tool’s compact and lightweight construction enhances user comfort, making it ideal for both professional and hobbyist use. Its intuitive controls minimize the learning curve for new users.

- Versatile Applications: Suitable for a wide range of acrylic thicknesses and shapes, the tool adapts to diverse project requirements, from simple curves to complex 3D forms.

- Durable Construction: Built with high-quality materials, the tool is designed to withstand frequent use while maintaining optimal performance over time.

Image: A Acrylic Heat Bender Tool-Type A in action, shaping a lampshade.

Advantages of the Acrylic Heat Bender Tool-Type A

The Acrylic Heat Bender Tool-Type A offers several distinct advantages that set it apart from traditional methods of acrylic shaping:

- Time Efficiency: By eliminating the need for manual heating and bending, the tool significantly reduces the time required to complete projects. This is particularly beneficial for industrial applications where speed and consistency are critical.

- Cost-Effectiveness: The tool minimizes material waste by ensuring precise bends, which reduces the need for rework and saves on raw material costs. This makes it an economical choice for both small-scale and large-scale operations.

- User-Friendly Operation: With its straightforward design and minimal setup time, the tool is accessible to users of all skill levels. This democratizes the acrylic shaping process, enabling even beginners to achieve professional results.

- Enhanced Safety: The tool’s built-in safety features, such as automatic shut-off and temperature regulation, reduce the risk of burns and other accidents, ensuring a safer working environment.

Image: A Acrylic Heat Bender Tool-Type A used to create a 3D trim cap.

Technical Specifications

| Parameter | Details |

|---|---|

| Model | Type A |

| Material | High-grade aluminum alloy and heat-resistant plastic components |

| Dimensions | 300mm x 150mm x 100mm |

| Temperature Range | 100°C to 200°C (adjustable) |

| Power Consumption | 150W |

| Weight | 1.2kg |

| Compatibility | Acrylic sheets up to 5mm thickness |

The Acrylic Heat Bender Tool-Type A is designed to meet the rigorous demands of modern manufacturing. Its technical specifications reflect a balance between portability, power, and precision, making it suitable for a wide range of applications.

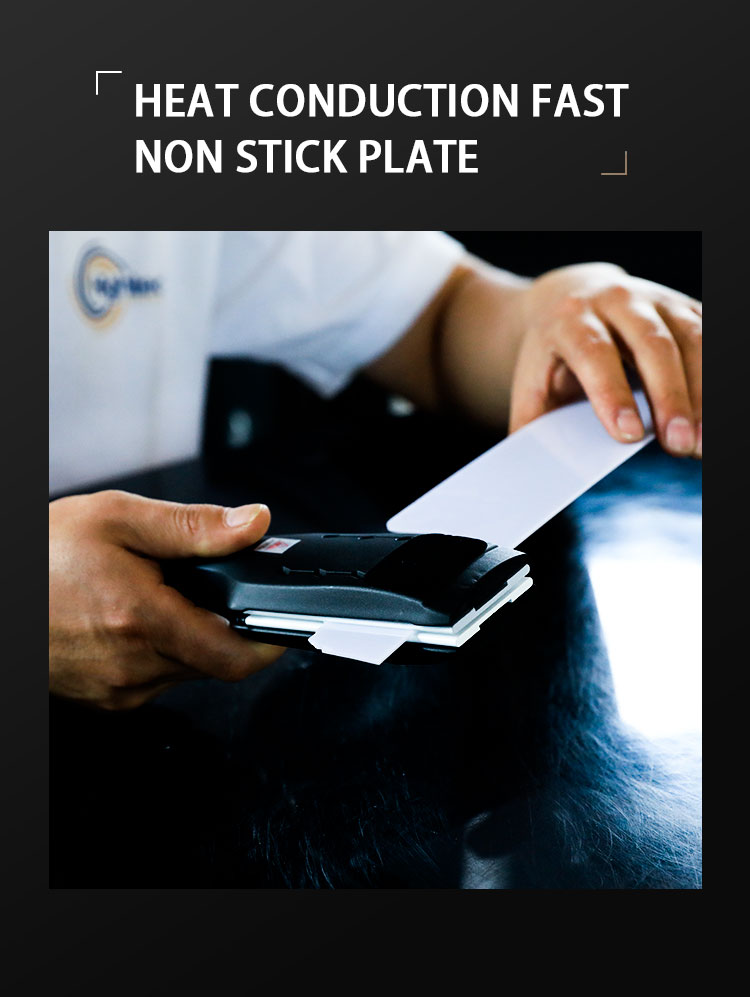

Image: A close-up view of the Acrylic Heat Bender Tool-Type A.

Application Scenarios

The versatility of the Acrylic Heat Bender Tool-Type A makes it a valuable asset in various industries and projects:

- Industrial Manufacturing: The tool is widely used in the production of acrylic signage, displays, and custom components. Its precision and efficiency help manufacturers meet tight deadlines while maintaining high-quality standards.

- Art and Design: Artists and designers leverage the tool to create intricate acrylic sculptures, decorative elements, and custom furniture. Its ability to handle complex shapes allows for greater creative freedom.

- DIY and Hobby Projects: Enthusiasts use the tool for home improvement projects, such as crafting acrylic light covers, lampshades, and decorative panels. Its user-friendly design makes it accessible to non-professionals.

- Educational Institutions: Schools and training centers incorporate the tool into their curricula to teach students about material science, manufacturing processes, and hands-on craftsmanship.

Image: A Acrylic Heat Bender Tool-Type A being exported to international markets.

Company Background: Hebei Pulongte Rubber and Plastic Technology Co., Ltd.

Founded with a vision to revolutionize the plastics and rubber industry, Hebei Pulongte Rubber and Plastic Technology Co., Ltd. has established itself as a leader in innovative manufacturing solutions. The company specializes in the development and production of high-quality tools and materials, including the Acrylic Heat Bender Tool-Type A.

Hebei Pulongte’s commitment to innovation and quality is evident in its state-of-the-art facilities and rigorous testing protocols. The company adheres to international standards, ensuring that its products meet the highest levels of performance and reliability. This dedication has earned Hebei Pulongte a reputation for excellence, with its products being exported to numerous countries worldwide.

Image: A Acrylic Heat Bender Tool-Type A price list.

Why Choose Hebei Pulongte?

There are several compelling reasons to choose Hebei Pulongte Rubber and Plastic Technology Co., Ltd. for your acrylic shaping needs:

- Comprehensive Product Line: The company offers a wide range of tools and materials, including the Acrylic Heat Bender Tool-Type A, ensuring that customers can find everything they need in one place.

- Global Reach: With a strong presence in international markets, Hebei Pulongte provides reliable sourcing and distribution services, making it easier for businesses to access high-quality products.

- Customer-Centric Approach: The company prioritizes customer satisfaction through personalized support, competitive pricing, and timely delivery. This focus on service ensures that clients receive value at every stage of the purchasing process.

- Sustainability Commitment: Hebei Pulongte is dedicated to environmentally responsible practices, including the use of eco-friendly materials and energy-efficient manufacturing processes.

Image: The Hebei Pulongte Rubber and Plastic Technology Co., Ltd. headquarters.

Industry Standards and Certifications

The Acrylic Heat Bender Tool-Type A is designed in accordance with NIST (National Institute of Standards and Technology) guidelines, which emphasize the importance of precision and reliability in manufacturing. According to NIST, "Standards and measurements are fundamental to innovation, ensuring that products meet the required quality and safety benchmarks" (NIST, 2025).

Hebei Pulongte’s adherence to these standards underscores its commitment to excellence. The company’s products are subject to rigorous testing and certification processes, ensuring compliance with both national and international regulations.

Conclusion

The Acrylic Heat Bender Tool-Type A is a testament to the power of innovation and engineering. By combining precision, efficiency, and user-friendly design, this tool empowers users to achieve exceptional results in acrylic shaping. Backed by the expertise of Hebei Pulongte Rubber and Plastic Technology Co., Ltd., the tool represents a reliable and cost-effective solution for a wide range of applications.

As the demand for high-quality acrylic products continues to grow, the Acrylic Heat Bender Tool-Type A stands out as a vital tool for manufacturers, artisans, and hobbyists. With its robust features and proven performance, it is poised to become an industry standard in the field of acrylic shaping.

References

NIST (National Institute of Standards and Technology). (2025). Driving Innovation: The Role of Standards in Manufacturing. Retrieved from https://www.nist.gov

-

Comprehensive Guide to White PVC Material: Benefits, Applications & Innovations

NewsNov.24,2025

-

Flat Hard Plastic PP Flexible Strips: Durable, Flexible, and Sustainable Solutions for Modern Industry

NewsNov.24,2025

-

Understanding Soft PVC Slip Cover Tuck Grip – Global Uses & Benefits

NewsNov.23,2025

-

Discover the Practical Benefits and Global Use of Square Plastic Tubes

NewsNov.23,2025

-

Understanding Led Lampshade Diffuser PC Covers – Benefits, Trends & Buying Guide

NewsNov.22,2025

-

Durable, Cost-Effective PVC Rectangular Grey Tube for Frame Solutions | Pulongte

NewsNov.22,2025