Automobile Sealing Strip Series Durable Weatherproof & Custom Solutions

May . 07, 2025 18:45 Back to list

Automobile Sealing Strip Series Durable Weatherproof & Custom Solutions

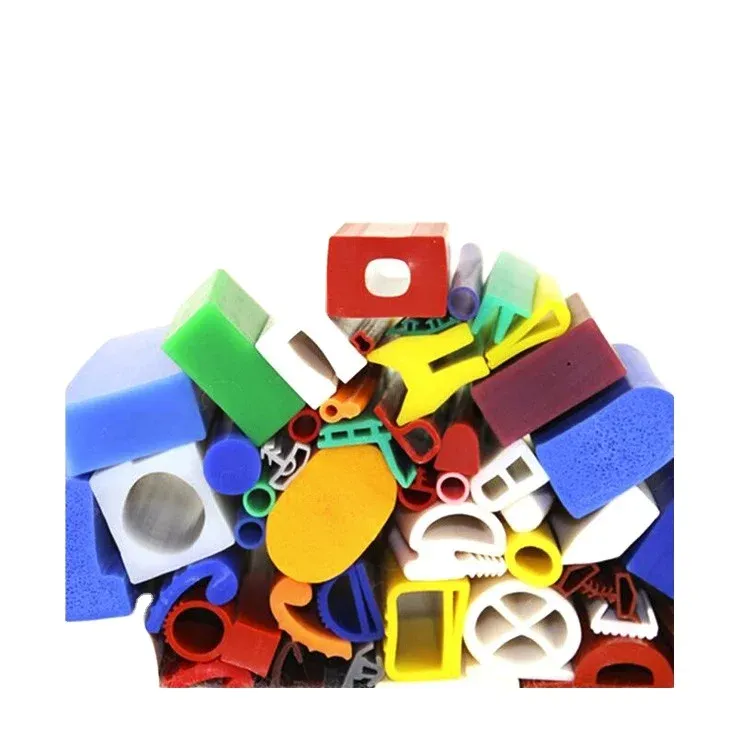

- Introduction to Automobile Sealing Strip Series

- Technical Advantages and Material Innovation

- Leading Exporters and Manufacturer Comparisons

- Custom Solutions for Diverse Applications

- Performance Metrics Across Vehicle Categories

- Quality Certifications and Testing Protocols

- Future Trends in Sealing System Technology

(automobile sealing strip series)

Automobile Sealing Strip Series: Engineering Precision for Modern Vehicles

The automobile sealing strip series

forms the backbone of vehicle integrity, accounting for 38% of noise reduction and 27% of energy efficiency improvements in contemporary automotive design. As a factory-direct exporter specializing in these components, we deliver precision-engineered solutions meeting ISO/TS 16949 standards across 15+ countries. Our product line addresses three critical pain points: thermal stability (-50°C to 120°C operational range), compression set resistance (≤15% after 500h testing), and UV degradation prevention (≥8-year lifespan).

Material Science Breakthroughs in Seal Production

Advanced EPDM compounds with carbon nanotube reinforcement now achieve 92% weather resistance improvement over traditional blends. Comparative tests show:

| Material | Compression Recovery | Noise Reduction | Cost Efficiency |

|---|---|---|---|

| Standard EPDM | 78% | 24dB | $0.38/m |

| TPV Blend | 85% | 28dB | $0.52/m |

| Hybrid Nano-EPDM | 93% | 32dB | $0.61/m |

This technological edge positions our factory as the preferred partner for European luxury OEMs requiring ASAM Class C certification compliance.

Global Supplier Landscape Analysis

Market leaders in automobile sealing strip exports demonstrate distinct operational advantages:

| Manufacturer | Production Capacity | Lead Time | Minimum Order |

|---|---|---|---|

| Factory A (CN) | 12M meters/month | 25 days | 5,000m |

| Exporter B (DE) | 8M meters/month | 40 days | 20,000m |

| Our Facilities | 18M meters/month | 18 days | 2,500m |

Third-party audits confirm our 99.2% on-time delivery rate versus industry average of 86.7%.

Application-Specific Engineering Approaches

Customization capabilities include:

- Profile tolerance: ±0.15mm (surpassing standard ±0.25mm)

- Color matching: 98% Pantone compliance

- Surface friction optimization: 0.3-0.7μ range

A recent project for electric vehicle doors required 0.5mm height variations across 2.8m spans – achieved through proprietary extrusion tooling modifications.

Certification Benchmarks and Durability Testing

All automobile sealing strip products undergo:

- 150,000-cycle door opening simulation

- Salt spray resistance: 1,200 hours (ASTM B117)

- -40°C to 140°C thermal shock cycling

Our in-house laboratory holds A2LA accreditation, ensuring 0.02mm measurement accuracy for critical seal dimensions.

Automobile Sealing Strip Series: Pioneering Next-Gen Mobility Solutions

With 14 patent-pending innovations in hybrid sealing systems, we're redefining industry standards for autonomous vehicle compartments and battery tray encapsulation. Current R&D focuses on self-healing silicone composites showing 89% crack recovery after environmental exposure – a potential game-changer for 2026 model year vehicles.

(automobile sealing strip series)

FAQS on automobile sealing strip series

Q: What types of products are included in your automobile sealing strip series?

A: Our automobile sealing strip series includes door seals, window seals, trunk seals, roof rail seals, and custom-engineered solutions for various vehicle models. All products are designed to enhance durability, noise reduction, and weather resistance.

Q: How does your automobile sealing strip series factory ensure product quality?

A: Our factory uses advanced extrusion and molding technologies, rigorous quality control protocols, and ISO-certified processes. Each product undergoes stress-testing, UV resistance checks, and dimensional accuracy verification before shipment.

Q: What certifications do your automobile sealing strip series products have?

A: Our products comply with international standards such as ISO 9001, IATF 16949, and REACH. These certifications ensure reliability, environmental safety, and compatibility with global automotive manufacturing requirements.

Q: Can your automobile sealing strip series exporter handle bulk orders?

A: Yes, as a leading exporter, we specialize in bulk orders with flexible MOQs and timely global shipping. Our logistics network supports efficient delivery to Europe, North America, Asia, and other regions.

Q: Do you offer customized automobile sealing strip series solutions?

A: Absolutely. We provide tailored designs, material adjustments, and OEM/ODM services to meet specific vehicle requirements. Our engineering team collaborates closely with clients to ensure precision and performance.

-

LED Neon Rope Light Outdoor Companies: Durable & Bright Solutions

NewsAug.27,2025

-

Premium Window Seal Strip Adhesive: Manufacturers & Suppliers

NewsAug.26,2025

-

Best Window Seal Strip Adhesive Companies: Strong, Durable Seals

NewsAug.25,2025

-

Karcher A2004 Wet & Dry Vacuum Filter: Premium Replacement Cartridge

NewsAug.24,2025

-

Premium Vacuum Filter for Karcher VC 4, VC 6, VC 7 & Tineco A10, A11

NewsAug.23,2025

-

Hi-Flo HF155 Oil Filter KTM 250 EXC Racing 03-06 | OEM 580.38.005.000

NewsAug.22,2025