Leading Window Seal Strip Adhesive Companies | Durable & Weatherproof

Aug . 28, 2025 02:00 Back to list

Leading Window Seal Strip Adhesive Companies | Durable & Weatherproof

The Crucial Role of Advanced Sealing Solutions in Modern Industries

In the intricate landscape of industrial and commercial applications, the integrity of sealing solutions is paramount. From maintaining thermal efficiency in high-temperature ovens to ensuring environmental protection in critical infrastructure, the demand for robust and reliable sealing components is consistently growing. This article delves into the specialized domain of window seal strip adhesive companies, exploring their indispensable contributions to various sectors. These entities are not merely manufacturers; they are innovators providing essential components that uphold operational safety, energy efficiency, and regulatory compliance across a multitude of applications.

We will explore the technical nuances, market trends, and strategic advantages offered by leading window seal strip adhesive companies, emphasizing how their specialized products address complex engineering challenges and contribute significantly to the longevity and performance of industrial equipment and infrastructure.

Current Industry Trends and Market Dynamics for Sealing Solutions

The market for window seal strip adhesive products is experiencing dynamic growth, driven by several key factors including stringent environmental regulations, increasing demand for energy-efficient solutions, and advancements in material science. The global industrial seals market size was valued at USD 12.8 billion in 2022 and is projected to reach USD 17.5 billion by 2030, growing at a CAGR of 4.0% from 2023 to 2030 (Source: Grand View Research). This expansion highlights the critical importance of reliable sealing components.

- Emphasis on Sustainability: There is a growing preference for eco-friendly materials and manufacturing processes. Window seal strip adhesive factories are increasingly focusing on recyclable materials and production methods that minimize waste and energy consumption.

- High-Performance Materials: The demand for seals capable of withstanding extreme temperatures, aggressive chemicals, and high pressures is escalating, particularly in sectors like aerospace, automotive, and petrochemicals. Silicone, EPDM, and fluorocarbon elastomers are gaining traction due to their superior properties.

- Customization and Precision Engineering: As applications become more specialized, the need for custom-designed window seal strip adhesive products has intensified. Window seal strip adhesive manufacturers leverage advanced CAD/CAM systems and rapid prototyping to meet bespoke client requirements.

- Digitization in Manufacturing: Industry 4.0 principles, including automation, IoT, and data analytics, are being integrated into the production processes of leading window seal strip adhesive companies to enhance efficiency, reduce costs, and improve product quality.

These trends underscore the evolving landscape where innovation, quality, and adaptability are crucial for any successful window seal strip adhesive supplier or window seal strip adhesive exporter.

The Manufacturing Process: A Deep Dive into Window Seal Strip Production

The production of high-performance window seal strips, such as silicone rubber gaskets for oven door window seals, involves a meticulously controlled multi-stage process. This ensures the final product meets rigorous industry standards for durability, thermal resistance, and sealing effectiveness. A typical process flow within a modern window seal strip adhesive factory includes:

Process Flow for Silicone Sealing Strips:

-

1. Material Selection & Compounding:

High-grade silicone raw materials (polydimethylsiloxane polymer) are selected based on application requirements (e.g., specific shore hardness, temperature resistance, chemical inertness). Additives such as fillers (e.g., fumed silica for strength), cross-linking agents (peroxides or platinum catalysts for vulcanization), pigments, and processing aids are precisely weighed and blended in a two-roll mill or internal mixer to create a homogeneous silicone compound. This critical step determines the physical and chemical properties of the final product.

-

2. Extrusion or Molding:

Depending on the profile complexity and volume, the compounded silicone is either extruded or molded.

- Extrusion: For continuous profiles (strips, cords), the compound is fed into an extruder, where it is forced through a die under pressure and heat, forming the desired cross-sectional shape.

- Molding: For complex or custom geometries (e.g., specific gasket shapes), compression molding or injection molding techniques are employed. The compound is placed into heated molds where it cures under pressure.

-

3. Vulcanization (Curing):

The extruded or molded silicone profiles undergo vulcanization, a process where the polymer chains cross-link, transforming the material from a plastic state into an elastic rubber. This is typically done in continuous hot air ovens or autoclaves for extruded profiles, or within the heated molds for molded parts. Precise temperature and time control are crucial for achieving optimal mechanical properties and service life.

-

4. Post-Curing (Optional but Recommended):

For critical applications, especially those involving high temperatures or food/medical contact, products undergo post-curing. This involves heating the fully cured silicone at elevated temperatures for an extended period to remove volatile byproducts and enhance physical properties, ensuring compliance with standards like FDA or specific automotive requirements.

-

5. Cutting, Splicing, and Finishing:

The continuous strips are cut to specified lengths. For applications requiring closed-loop gaskets (e.g., oven door seals), the cut ends are joined using specialized hot vulcanization or adhesive bonding techniques to create a seamless seal. Additional finishing steps might include punching holes, applying adhesive backing, or surface treatments.

-

6. Quality Control & Testing:

Throughout the process, stringent quality control measures are implemented. Products are tested against internal specifications and external standards like ASTM D2000, ISO 3302, and UL certifications for properties such as dimensional accuracy, tensile strength, elongation, tear resistance, compression set, specific gravity, heat aging, and chemical resistance. This ensures the products meet the required service life and performance in target industries like petrochemical, metallurgy, and water supply & drainage.

This meticulous process ensures that window seal strip adhesive companies deliver products that offer superior advantages such as enhanced energy saving through effective thermal insulation, excellent corrosion resistance against harsh chemicals, and extended service life in demanding operational environments.

Precision manufacturing for consistent window seal strip quality.

Technical Specifications and Performance Parameters

Understanding the precise technical specifications is crucial for selecting the right window seal strip adhesive products. For instance, the Silicone Sealing Strip Silicone rubber gasket for oven door window seals, a flagship product from many window seal strip adhesive manufacturers, offers a superior combination of properties suitable for high-temperature and demanding environments.

Typical Product Specification Table: Silicone Oven Door Gasket

These parameters are critical in determining suitability for industrial applications, ensuring reliability and compliance with safety and operational standards. A reputable window seal strip adhesive company will provide detailed datasheets for all their products.

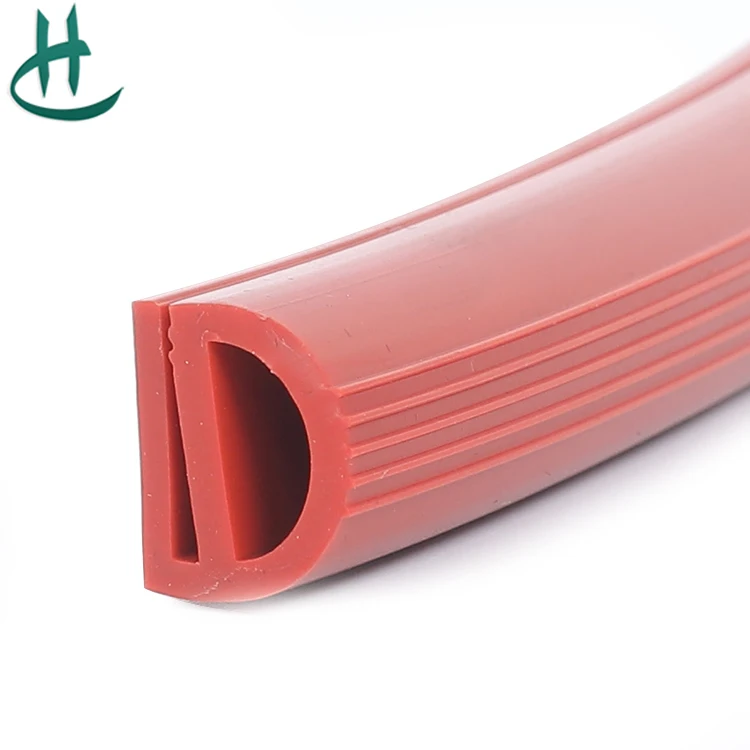

A closer look at silicone sealing strip integrity.

Application Scenarios Across Diverse Industries

The versatility of window seal strip adhesive products means they are indispensable across a wide spectrum of industries, providing crucial sealing functions that ensure operational efficiency, safety, and longevity of equipment. Here are key application scenarios:

- Petrochemical Industry: In oil and gas refineries, chemical processing plants, and offshore platforms, seals are vital for preventing leaks of corrosive and volatile substances. Silicone and fluorosilicone seals offer excellent resistance to hydrocarbons, solvents, and extreme temperatures, crucial for furnace doors, inspection windows, and pipeline access points.

- Metallurgy & Foundry Operations: High-temperature sealing strips are essential for blast furnaces, industrial ovens, kilns, and heat treatment equipment. They help maintain stable internal temperatures, prevent heat loss, and protect sensitive components from molten metal splash or abrasive dust. EPDM and specialized silicone compounds are frequently employed.

- Food & Beverage Processing: FDA-compliant silicone gaskets are extensively used in ovens, sterilization equipment, refrigerators, and processing lines where hygiene is paramount. Their non-toxic, odorless, and high-temperature resistant properties make them ideal for sealing access panels and inspection windows, ensuring product purity and preventing contamination.

- Water Supply & Drainage Systems: EPDM and PVC seals are widely used in water treatment plants, pumping stations, and pipe networks. They provide watertight seals for access hatches, inspection covers, and valve enclosures, preventing leakage and ingress of contaminants, crucial for maintaining system integrity and public health.

- HVAC & Construction: For commercial buildings and industrial facilities, window seal strips contribute significantly to energy efficiency by sealing windows, doors, and access panels, reducing drafts and heat transfer. This directly translates to lower heating and cooling costs, aligning with green building initiatives.

- Automotive & Transportation: Beyond typical window seals, specialized adhesive strips are used in vehicle manufacturing for components requiring robust environmental sealing, such as battery compartments in electric vehicles, engine bay components, and access panels in heavy-duty vehicles, protecting against moisture, dust, and vibrations.

The ability of window seal strip adhesive exporters and suppliers to provide application-specific solutions underscores their value to these critical sectors.

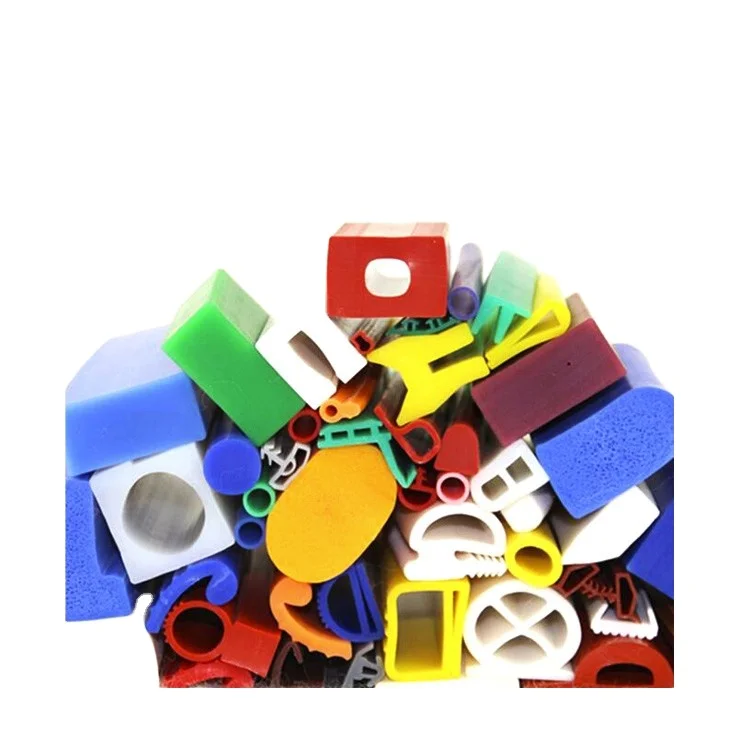

Customized profiles for diverse industrial needs.

Technical Advantages and Value Proposition

Choosing advanced window seal strip adhesive products from specialized window seal strip adhesive companies brings a multitude of technical advantages that translate directly into operational and economic benefits for B2B clients:

- Superior Thermal Insulation & Energy Saving: High-performance silicone and EPDM seals significantly reduce heat transfer across sealed interfaces. In industrial ovens, kilns, or refrigerated units, this directly translates to lower energy consumption (e.g., up to 15-20% reduction in thermal energy loss in a well-sealed industrial oven), contributing to substantial operational cost savings and reduced carbon footprint.

- Exceptional Corrosion and Chemical Resistance: Formulated with materials like specific grades of silicone or fluorocarbon rubber, these seals withstand exposure to aggressive chemicals, acids, bases, and industrial solvents. This prolongs the life of the seal and the equipment it protects, minimizing downtime for maintenance and replacement.

- Extended Service Life and Durability: Engineered for resilience against environmental factors such as UV radiation, ozone, extreme temperatures, and mechanical stress (e.g., compression set resistance), quality window seal strips offer a significantly longer service life compared to generic alternatives. This reduces the total cost of ownership (TCO) by decreasing replacement frequency.

- Enhanced Operational Safety: By preventing leaks of hazardous materials, containing high temperatures, and isolating electrical components, these seals play a critical role in maintaining a safe working environment and ensuring compliance with occupational safety standards.

- Vibration Dampening & Noise Reduction: Elastomeric seals also absorb vibrations and dampen noise, contributing to a more stable and quieter operation of machinery, enhancing worker comfort and equipment longevity.

- Aesthetic and Functional Integration: Beyond pure performance, modern sealing solutions can be designed for seamless integration, offering aesthetic advantages and simplifying installation processes.

These inherent advantages underscore why investing in premium window seal strip adhesive products is a strategic decision for any organization aiming for operational excellence and long-term reliability.

Vendor Comparison: Selecting the Right Window Seal Strip Adhesive Supplier

When sourcing window seal strip adhesive solutions, a thorough evaluation of potential suppliers is essential. Not all window seal strip adhesive factories or window seal strip adhesive exporters offer the same level of quality, technical support, or customization capabilities. Here's a comparative framework to aid in vendor selection:

Key Comparison Factors for Window Seal Strip Suppliers

Evaluating window seal strip adhesive quotes from various suppliers based on these criteria ensures a long-term, reliable partnership and optimal product performance.

Quality control is paramount for reliable sealing solutions.

Customized Solutions and Design Flexibility

One of the most significant advantages offered by leading window seal strip adhesive companies is their ability to provide highly customized solutions. Off-the-shelf products often cannot meet the precise requirements of unique industrial applications, which demand specific geometries, material compositions, and performance characteristics.

Customization involves:

- Profile Design: From complex multi-cavity designs for superior compression to intricate interlocking features, a skilled window seal strip adhesive manufacturer can engineer profiles to exact customer specifications.

- Material Formulation: Tailoring the silicone or rubber compound to achieve desired properties such as specific hardness, extreme temperature resistance (e.g., beyond 250°C), enhanced chemical resistance, flame retardancy (e.g., UL94 V-0), or FDA compliance for food-grade applications.

- Adhesive Backing: Applying specialized pressure-sensitive adhesives (PSAs) for easy installation, chosen for their compatibility with the substrate and operational environment (e.g., high-temperature resistant acrylic adhesives).

- Color Matching: Custom colors for aesthetic integration or functional coding.

- Value-Added Processes: Including precision cutting, splicing to form endless rings or frames, corner molding, and integration with other components.

Engaging with a window seal strip adhesive company that offers robust R&D and engineering support ensures that the sealing solution is perfectly aligned with the application's demands, optimizing performance and reducing design iterations.

Real-World Application Case Studies

Practical examples demonstrate the tangible benefits of choosing high-quality window seal strip adhesive products:

Case Study 1: High-Temperature Oven Manufacturer

A leading industrial oven manufacturer faced persistent issues with premature gasket failure on their continuous-belt ovens, operating at temperatures up to 200°C. Standard EPDM seals degraded rapidly, leading to heat loss, increased energy consumption, and frequent maintenance. A specialized window seal strip adhesive manufacturer engineered a custom silicone foam gasket with enhanced compression set resistance and a reinforced core. The new seals demonstrated a five-fold increase in service life, reduced energy consumption by 18%, and significantly lowered maintenance costs, improving oven efficiency and end-user satisfaction.

Case Study 2: Chemical Processing Plant

A plant processing highly corrosive acids required robust seals for their reactor inspection windows. Previous materials suffered from chemical attack and embrittlement, posing significant safety risks. A high-performance window seal strip adhesive company developed a custom fluorosilicone (FVMQ) sealing strip, offering superior chemical inertness and resistance to a broad range of aggressive media. The solution completely eliminated seal failures, drastically improving worker safety and plant operational reliability, and passing stringent ANSI B31.3 chemical compatibility tests.

Case Study 3: Pharmaceutical Sterilization Equipment

For pharmaceutical autoclaves, seals must withstand high-pressure steam sterilization cycles while maintaining a sterile environment. A window seal strip adhesive factory provided FDA 21 CFR 177.2600 compliant, platinum-cured silicone gaskets for the viewing windows and access doors. These seals exhibited minimal extractables, maintained integrity under repeated steam cycles up to 135°C, and ensured hermetic sealing, critical for preventing contamination and meeting strict regulatory requirements.

These case studies illustrate the tangible benefits of partnering with knowledgeable and experienced window seal strip adhesive companies.

Innovative solutions for complex sealing challenges.

Ensuring Trust and Reliability: Elements

Authoritativeness and Certifications

Reputable window seal strip adhesive companies distinguish themselves through verifiable credentials and a commitment to quality. This often includes:

- ISO 9001:2015 Certification: Demonstrates a robust quality management system.

- ISO/TS 16949 (now IATF 16949): For automotive sector suppliers, indicating adherence to specific quality standards.

- FDA 21 CFR 177.2600 Compliance: For silicone products intended for food and beverage contact.

- REACH & RoHS Compliance: Ensuring environmental and health safety for European markets.

- UL Listings (e.g., UL 94 V-0): For flame retardant properties, critical in certain applications.

- Long-standing Industry Presence & Partner Clients: Decades of experience and partnerships with major industrial players signify consistent reliability and expertise.

Frequently Asked Questions (FAQ)

Q: What is the typical service life of a silicone window seal strip in an industrial oven?

A: With continuous operation at its rated maximum temperature (e.g., 230°C for standard silicone), a high-quality silicone seal can last 3-5 years or more. Factors like chemical exposure, frequent temperature cycling, and mechanical abrasion can influence this. Regular inspection is recommended.

Q: Can window seal strip adhesive products be customized for specific dimensions or shapes?

A: Absolutely. Leading window seal strip adhesive companies specialize in custom extrusion and molding. Providing detailed CAD drawings or physical samples allows engineers to design a seal tailored to your exact application, including custom profiles, lengths, and corner fabrications.

Q: How do I choose the correct material (e.g., Silicone vs. EPDM) for my application?

A: Material selection depends on the operational environment:

- Silicone: Excellent for high/low temperatures (-60°C to +230°C), UV/ozone resistance, good electrical insulation, typically for food/medical contact. Less suitable for strong acids/bases or steam without special formulation.

- EPDM: Excellent for outdoor use, weathering, ozone, and steam resistance, good with polar solvents, hot water. Poor for oil/petroleum products.

Lead Time and Fulfillment

Standard window seal strip adhesive products typically have a lead time of 2-4 weeks, depending on order volume and current production schedules. Custom-engineered solutions may require 6-8 weeks, including design, tooling, and sample approval. Expedited options are often available for urgent requirements, though this may incur additional costs. Effective inventory management and robust supply chain logistics ensure on-time delivery for window seal strip adhesive exporters.

Warranty Commitments and Customer Support

Most reputable window seal strip adhesive companies offer a standard warranty against manufacturing defects, typically ranging from 12 to 24 months from the date of shipment. Comprehensive after-sales support includes technical assistance for installation, troubleshooting, and material selection. Dedicated customer service teams ensure prompt responses to inquiries and efficient handling of any performance issues, underscoring a commitment to customer satisfaction and long-term partnership.

Dedicated customer support and quality assurance.

Conclusion: Partnering for Performance and Reliability

The selection of appropriate sealing solutions is a critical decision that profoundly impacts operational efficiency, safety, and cost-effectiveness across diverse industrial sectors. As demonstrated, discerning the capabilities and offerings of various window seal strip adhesive companies goes beyond mere product procurement; it involves establishing a strategic partnership with a supplier that can deliver consistent quality, technical innovation, and dependable support.

By prioritizing manufacturers and exporters who adhere to stringent quality standards, offer extensive customization options, and provide robust technical and after-sales service, businesses can ensure the longevity and optimal performance of their equipment, mitigating risks and maximizing return on investment. The future of industrial sealing lies in continuous innovation and collaboration between end-users and expert window seal strip adhesive suppliers.

References

- Grand View Research. "Industrial Seals Market Size, Share & Trends Analysis Report By Product (Mechanical Seals, Gaskets & Seals, Oil Seals, Other Seals), By Material (Elastomers, Metals, Others), By End-use, By Region, And Segment Forecasts, 2023 - 2030." Published July 2023.

- ASTM International. "Standard Test Method for Rubber Property—Compression Set—Constant Deflection in a Series of Standards." ASTM D395.

- ISO. "Rubber and plastics hoses and hose assemblies — Methods of test for physical properties — Part 1: Measurement of dimensions." ISO 3302-1:2014.

- UL Solutions. "Flammability of Plastic Materials for Parts in Devices and Appliances." UL 94.

- U.S. Food and Drug Administration. "21 CFR 177.2600 Rubber articles intended for repeated use." Last updated April 1, 2024.

-

Comprehensive Guide to White PVC Material: Benefits, Applications & Innovations

NewsNov.24,2025

-

Flat Hard Plastic PP Flexible Strips: Durable, Flexible, and Sustainable Solutions for Modern Industry

NewsNov.24,2025

-

Understanding Soft PVC Slip Cover Tuck Grip – Global Uses & Benefits

NewsNov.23,2025

-

Discover the Practical Benefits and Global Use of Square Plastic Tubes

NewsNov.23,2025

-

Understanding Led Lampshade Diffuser PC Covers – Benefits, Trends & Buying Guide

NewsNov.22,2025

-

Durable, Cost-Effective PVC Rectangular Grey Tube for Frame Solutions | Pulongte

NewsNov.22,2025