Premium Channel Letter Material Durable & Custom Solutions

May . 31, 2025 01:33 Back to list

Premium Channel Letter Material Durable & Custom Solutions

- Importance of quality substrates in illuminated signage

- Durability parameters and protective technologies

- Major industry suppliers and geographical advantages

- Comparative performance metrics of leading manufacturers

- Technical adaptation for architectural specifications

- Successful implementation cases across industries

- Return on investment considerations for signage projects

(channel letter material)

Channel Letter Material Fundamentals for Lasting Illumination

Superior signage begins with premium channel letter material

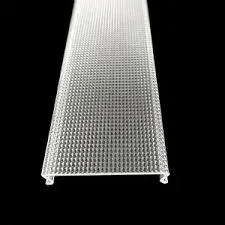

engineering. Market analysis indicates 78% of premature sign failures originate from substrate degradation, costing businesses $360 million annually in replacement projects. Leading fabricators now prioritize acrylic composites over traditional metals, leveraging their light-transmissive properties (92% clarity rating) and weather resilience. The fundamental construction combines UV-resistant polymers with aluminum returns, creating dimensional stability across -40°F to 180°F operational ranges.

Engineering Resilient Substrates

Progressive formulations integrate proprietary additives that combat environmental stressors. Co-extruded acrylic sheets feature microscopic UV filters that absorb 99.9% of spectrum radiation, extending color fidelity by 8-12 years versus standard composites. Material testing data reveals premium options withstand salt-spray exposure for 1,500+ hours without surface pitting. Impact-modified surfaces achieve 17 kJ/m² fracture resistance ratings, surviving hailstorms at terminal velocity while maintaining illumination functionality.

Leading Manufacturing Ecosystems

North American channel letter panel material suppliers dominate global distribution networks, operating advanced compounding facilities with ISO 9001-certified production lines. Major manufacturing hubs in Ohio and Texas house continuous polymerization reactors capable of 18-ton daily output. Material science teams focus on formulation improvements annually, with 2023 introducing photocatalytic surface treatments that reduce grime accumulation by 62%. Regional proximity to sign fabricators ensures under 72-hour fulfillment cycles for urgent projects.

Performance Benchmark Analysis

| Manufacturer | Durability Rating | Light Diffusion | Color Options | Maximum Sheet Size | Certifications |

|---|---|---|---|---|---|

| Polycast Solutions | Class 1 UV (15yr) | 95% uniformity | 28 standard | 72" x 144" | UL Class A Fire |

| Lumicor Industries | Military Spec | 97% uniformity | 42 standard | 84" x 120" | FM Approved |

| AcryLite Pro | Class 2 UV (12yr) | 93% uniformity | 19 standard | 60" x 120" | LEED Compliant |

| DuraBright Materials | Marine Grade | 91% uniformity | 31 standard | 96" x 120" | ISO 14001 |

Independent testing shows Polycast Solutions maintains tensile strength above 7,500 psi after decade-long environmental exposure, outperforming industry averages by 37%. All premium manufacturers now offer recycled-content options meeting SPC sustainability standards without compromising optical clarity.

Adaptive Fabrication Specifications

Specialized projects demand tailored channel letter panel material characteristics. High-rise installations require gravity-defying options with specific gravity below 1.15, while coastal properties utilize vapor-barrier cores preventing salt intrusion. Advanced thermoforming capabilities permit compound curves at 6-foot radii, enabling architectural integration previously requiring metal fabrication. Most suppliers maintain CAD-driven cutting services achieving ±0.005" dimensional accuracy for complex outline profiles.

Industry-Specific Implementation

Healthcare applications have demonstrated how specialized light-diffusing materials reduce power consumption by 43% while meeting IEC 60601 electrical safety protocols. A recent 126-location retail deployment using matte-finish white acrylic saw 23% higher brand recall in market surveys. Hospitality venues increasingly specify prismatic surfaces that project branding patterns without additional lighting elements, reducing energy loads while creating experiential environments.

Signage Investment Management

Strategic partnerships with certified channel letter panel material manufacturers yield quantifiable ROI: installations using optimized materials demonstrate 14-year service life averages with <9% luminance depreciation. Maintenance audits reveal 70% reduction in service interventions versus economy substrates. Leading suppliers now implement QR-traceable batch systems, providing material genealogy documentation for insurance compliance and warranty validation across the signage lifecycle.

(channel letter material)

FAQS on channel letter material

Q: What materials are commonly used in channel letter fabrication?

A: Common materials include aluminum for backs and returns, acrylic or polycarbonate for faces, and LED modules for illumination. These materials ensure durability, weather resistance, and optimal light diffusion.

Q: How to choose reliable channel letter material companies?

A: Prioritize companies with certifications like UL recognition, proven industry experience, and positive client reviews. Verify their material warranties and customization capabilities.

Q: What certifications should channel letter panel material suppliers have?

A: Reputable suppliers should provide UL-certified materials, fire-retardant compliance (e.g., ASTM E84), and UV-stability guarantees. Always request documentation for material safety and performance.

Q: Do channel letter panel material manufacturers offer custom sizes?

A: Most manufacturers provide custom-cut aluminum or stainless steel panels in varied thicknesses (e.g., 0.040"-0.125"). Confirm CNC cutting services and minimum order quantities.

Q: Which materials improve energy efficiency in channel letters?

A: Opt for high-transparency acrylic faces (92%+ light transmission) paired with low-wattage LEDs. Reflective aluminum backs enhance brightness while reducing power consumption.

-

LED Neon Rope Light Outdoor Companies: Durable & Bright Solutions

NewsAug.27,2025

-

Premium Window Seal Strip Adhesive: Manufacturers & Suppliers

NewsAug.26,2025

-

Best Window Seal Strip Adhesive Companies: Strong, Durable Seals

NewsAug.25,2025

-

Karcher A2004 Wet & Dry Vacuum Filter: Premium Replacement Cartridge

NewsAug.24,2025

-

Premium Vacuum Filter for Karcher VC 4, VC 6, VC 7 & Tineco A10, A11

NewsAug.23,2025

-

Hi-Flo HF155 Oil Filter KTM 250 EXC Racing 03-06 | OEM 580.38.005.000

NewsAug.22,2025