Acrylic Heat Bender Tool-Type A|Precision Acrylic Bending, Industrial Manufacturing

Sep . 22, 2025 20:00 Back to list

Acrylic Heat Bender Tool-Type A|Precision Acrylic Bending, Industrial Manufacturing

Acrylic heat bender tool-type A represents a significant advancement in the field of thermoplastic shaping, offering unmatched precision, efficiency, and versatility for industrial and commercial applications. This article delves into the product's core features, technical specifications, and real-world applications, while also highlighting the expertise of its manufacturer, Hebei Pulongte Rubber and Plastic Technology Co., Ltd., a leader in polymer processing solutions.

Product Overview and Key Features

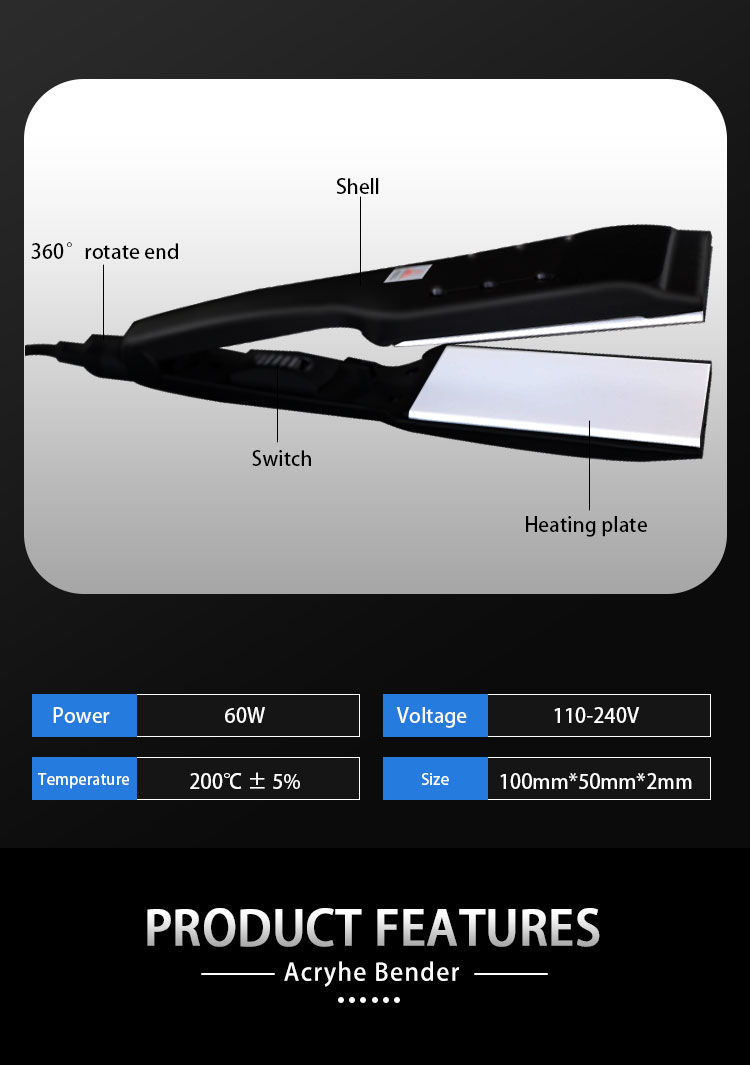

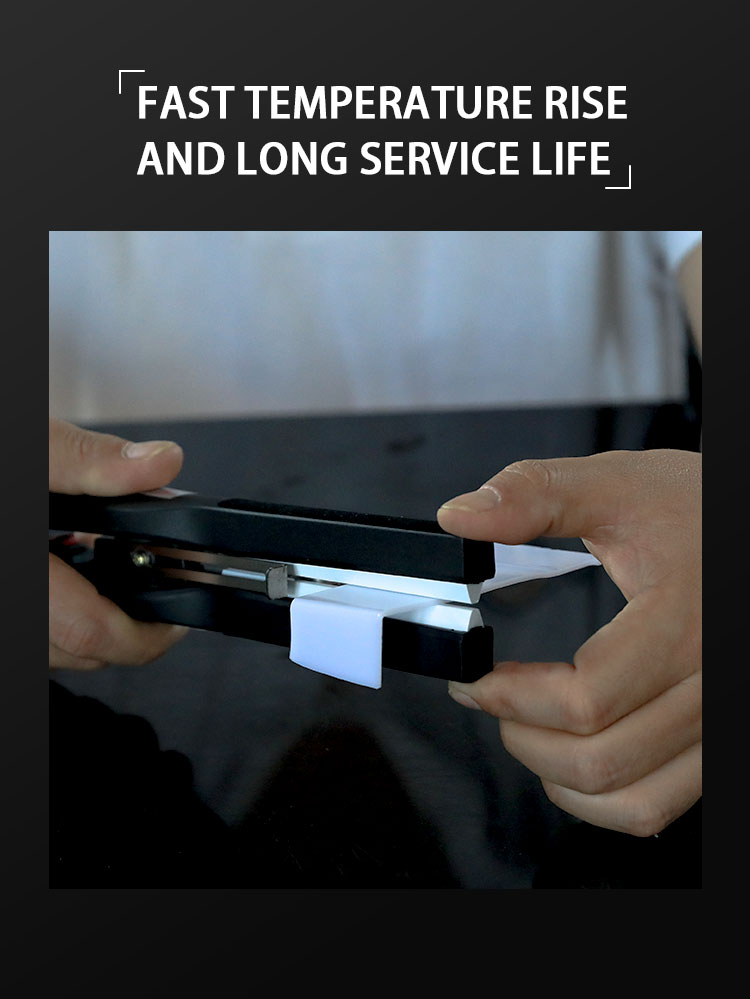

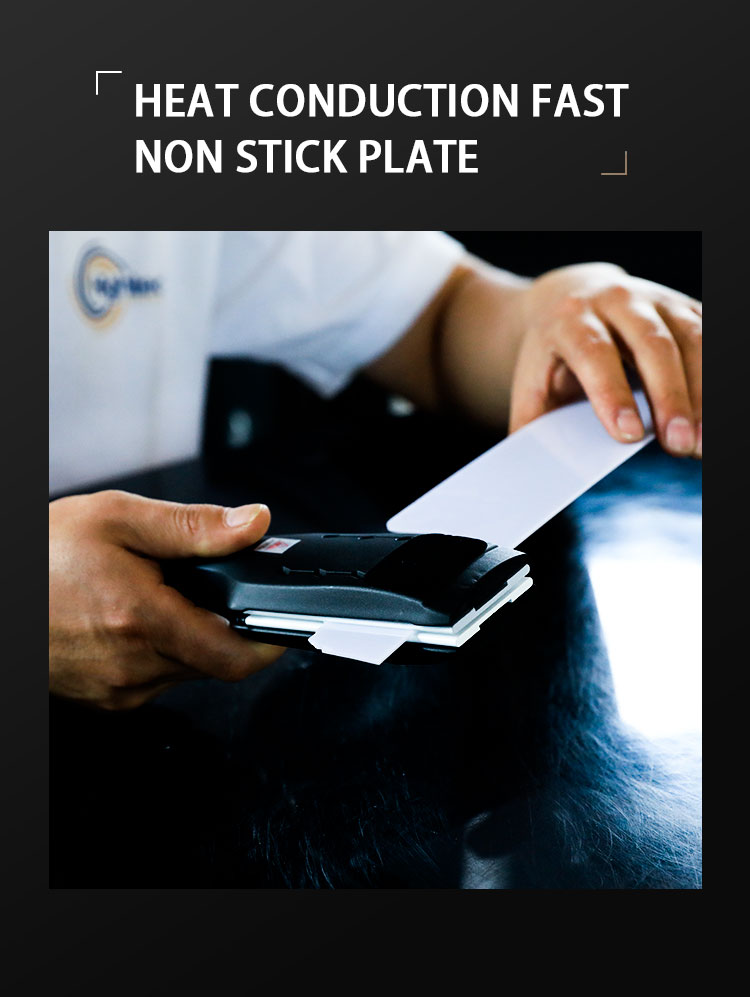

The Acrylic Heat Bender Tool-Type A is engineered to simplify the process of bending acrylic sheets into complex shapes. Its design integrates advanced thermal control systems, ergonomic ergonomics, and durable construction to meet the demands of modern manufacturing. Below are the key features that set this tool apart:

- High-Temperature Precision: The tool utilizes a calibrated heating element to reach optimal acrylic bending temperatures (typically 120-150°C), ensuring consistent results without warping or cracking.

- Adjustable Bending Jigs: Customizable molds and clamps allow for precise shaping of acrylic sheets into curves, angles, and 3D structures, catering to diverse design requirements.

- Durable Construction: Built with high-grade aluminum and heat-resistant materials, the tool withstands prolonged use in industrial environments.

- User-Friendly Interface: A digital temperature display and intuitive controls enable operators of all skill levels to achieve professional-grade outcomes.

Product Images

Below are visual representations of the Acrylic Heat Bender Tool-Type A and its related components:

Technical Specifications

The Acrylic Heat Bender Tool-Type A is designed to deliver exceptional performance. Below is a detailed specification table:

| Specification | Details |

|---|---|

| Heating Element | 1500W ceramic heating coil with PID temperature control |

| Temperature Range | 80°C – 180°C (adjustable via digital interface) |

| Material Compatibility | Acrylic (PMMA), Polycarbonate, PVC, and other thermoplastics |

| Dimensions | 450mm (L) x 300mm (W) x 200mm (H) |

| Weight | 12 kg (portable design for easy mobility) |

| Power Supply | 220V/50Hz (compatible with industrial and commercial outlets) |

| Safety Features | Overheat protection, automatic shut-off, and insulated handles |

Applications and Industry Use Cases

The versatility of the Acrylic Heat Bender Tool-Type A makes it indispensable across multiple sectors. Key applications include:

- Lighting Industry: Creating custom lampshades and diffusers with intricate designs (e.g.,

).

). - Architectural Design: Producing curved acrylic panels for partitions, ceilings, and signage.

- Automotive Manufacturing: Shaping acrylic components for dashboards, light covers, and decorative elements.

- Consumer Electronics: Fabricating transparent casings and protective covers for devices.

- 3D Printing and Prototyping: Preparing acrylic sheets for rapid prototyping and custom molds.

Company Background: Hebei Pulongte Rubber and Plastic Technology Co., Ltd.

As the manufacturer of the Acrylic Heat Bender Tool-Type A, Hebei Pulongte Rubber and Plastic Technology Co., Ltd. is a leading innovator in polymer processing solutions. Based in Hebei, China, the company specializes in developing high-precision tools for acrylic, polycarbonate, and other thermoplastic materials. With over a decade of expertise, Hebei Pulongte has established itself as a trusted partner for manufacturers seeking reliable and cost-effective solutions.

The company’s commitment to quality is reflected in its adherence to international standards such as ISO 9001 and its focus on sustainable manufacturing practices. Hebei Pulongte also offers customized tooling and technical support, ensuring that clients receive tailored solutions for their specific needs.

Why Choose the Acrylic Heat Bender Tool-Type A?

Several factors make the Acrylic Heat Bender Tool-Type A a preferred choice for professionals:

- Enhanced Efficiency: The tool reduces production time by eliminating the need for manual heating and bending, which can be time-consuming and prone to errors.

- Consistent Quality: The precise temperature control and adjustable jigs ensure uniform results, minimizing waste and rework.

- Cost-Effectiveness: By streamlining the bending process, the tool helps businesses lower labor costs and improve productivity.

- Scalability: Suitable for both small-scale workshops and large-scale industrial operations, the tool adapts to diverse production volumes.

Industry Standards and Certifications

The Acrylic Heat Bender Tool-Type A is designed to comply with global safety and performance standards. While specific certifications may vary, the product aligns with guidelines from organizations such as the National Institute of Standards and Technology (NIST), which plays a critical role in developing measurement standards for industrial equipment. According to NIST, "Precise thermal control systems are essential for ensuring the reliability of thermoplastic processing tools, as they directly impact product quality and safety" (NIST, 2025).

Conclusion

The Acrylic Heat Bender Tool-Type A exemplifies the synergy between innovation and practicality in modern manufacturing. With its advanced features, robust design, and wide-ranging applications, this tool is a game-changer for industries reliant on acrylic and thermoplastic materials. For more information on this product or to explore other solutions from Hebei Pulongte Rubber and Plastic Technology Co., Ltd., visit their official website or contact their sales team.

References

National Institute of Standards and Technology (NIST). (2025). Thermal Control in Industrial Manufacturing. Retrieved from https://www.nist.gov/

Back to Top-

Durable, Cost-Effective PVC Rectangular Grey Tube for Frame Solutions | Pulongte

NewsNov.22,2025

-

Durable Black PVC Price Strip for Efficient Labeling – Global Insights & Vendors

NewsNov.22,2025

-

Durable and Customizable PVC Profiles Strip for Construction & Industry | Pulongte

NewsNov.21,2025

-

Comprehensive Guide to PVC Extrusion Profiles | Durable & Sustainable Solutions

NewsNov.21,2025

-

Durable & Energy-Efficient Flat PVC Strip Solutions for Industry | Pulongte

NewsNov.20,2025

-

Durable and Customizable PVC Flat Profile Strips | Industrial & Construction Use

NewsNov.20,2025