Hightech Injection LED module-size6414: Bright, IP65, 12V?

Oct . 10, 2025 11:40 Back to list

Hightech Injection LED module-size6414: Bright, IP65, 12V?

Field notes on Hightech Injection LED module-size6414: why signmakers keep asking for it

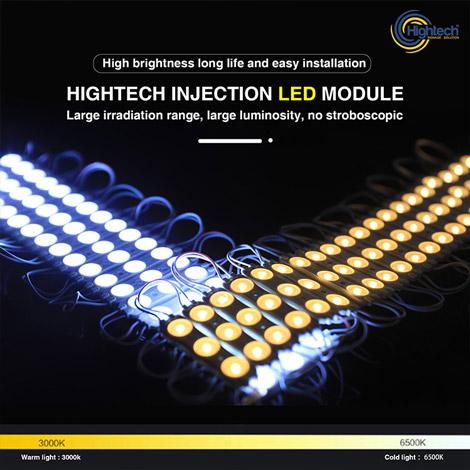

If you’ve been wrestling with hot spots in shallow lightboxes or channel letters, you probably know the drill: wide beam, stable 12V, and modules that actually survive weather. To be honest, that’s why the Hightech Injection LED module-size6414 keeps popping up in my inbox. It’s a 1.5W 2835-based, lens-equipped, DC12V mini module with a fat 160° spread, waterproofed for outdoor ads. Built in Qinghe County, Xingtai City (yes, the Hebei hub), it’s clearly aimed at installers who need predictable results, quickly.

What’s trending in LED modules right now

Three things: wider optics to kill shadows in slim boxes, higher efficacy 2835 packages, and simpler field wiring. This module leans into all three. In fact, the 160° lens is doing the heavy lifting—fewer modules per square meter without the zebra-striping effect. Many customers say they trim install time by “around 20–30%” on shallow 60–100 mm boxes.

Quick specification snapshot

| LED package | SMD 2835 (high-efficacy) |

| Power / Voltage | ≈1.5 W / DC12V (≈125 mA per module) |

| Optics | Injection lens, 160° nominal |

| Luminous flux | ≈120–150 lm (real-world use may vary) |

| CCT / CRI | Cool white 6000–7000 K / CRI ≥80 |

| Ingress rating | IP65–IP67 class build, sealed module |

| Dimensions | ≈64 × 14 × 7 mm (size “6414” form factor) |

| Stringing | Typically 20 pcs/string (check driver headroom) |

| Operating temp | −20 to +60 °C |

| Service life | L70 ≈50,000 h (TM‑21 projection from LM‑80 data) |

Where it shines (pun intended)

- Shallow lightboxes (60–120 mm) and halo channel letters

- Outdoor sign cabinets where IP sealing matters

- Retail fascias, transit ads, quick retrofit of legacy modules

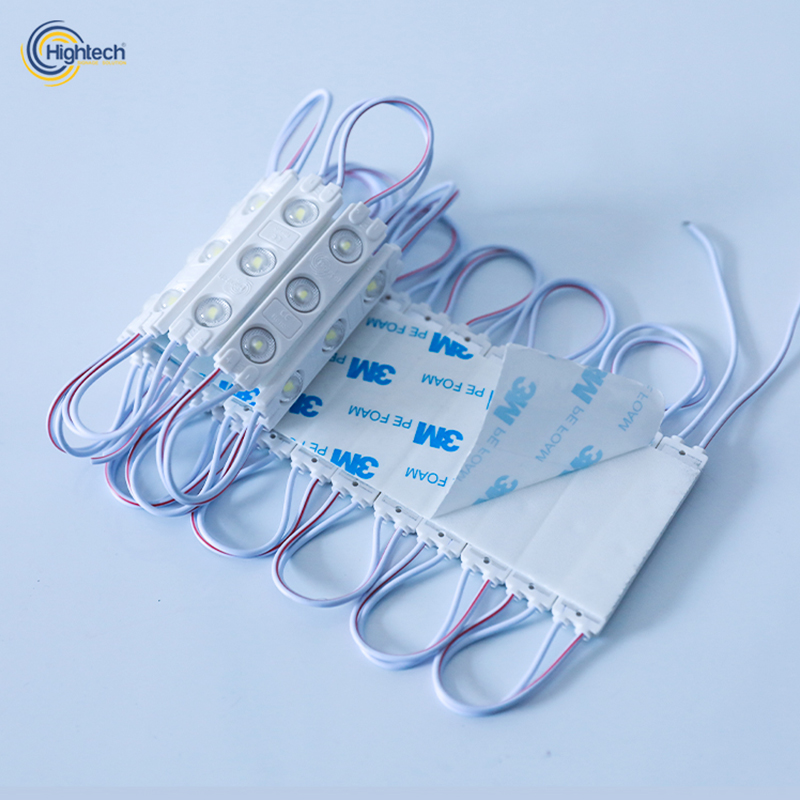

Advantages: wide-beam lens, stable 12V ecosystem, small footprint, and—surprisingly—less cabling clutter when you plan strings right. Installers I spoke with liked the peel-and-stick VHB pad plus screw slots. Simple but effective.

Materials, methods, and testing

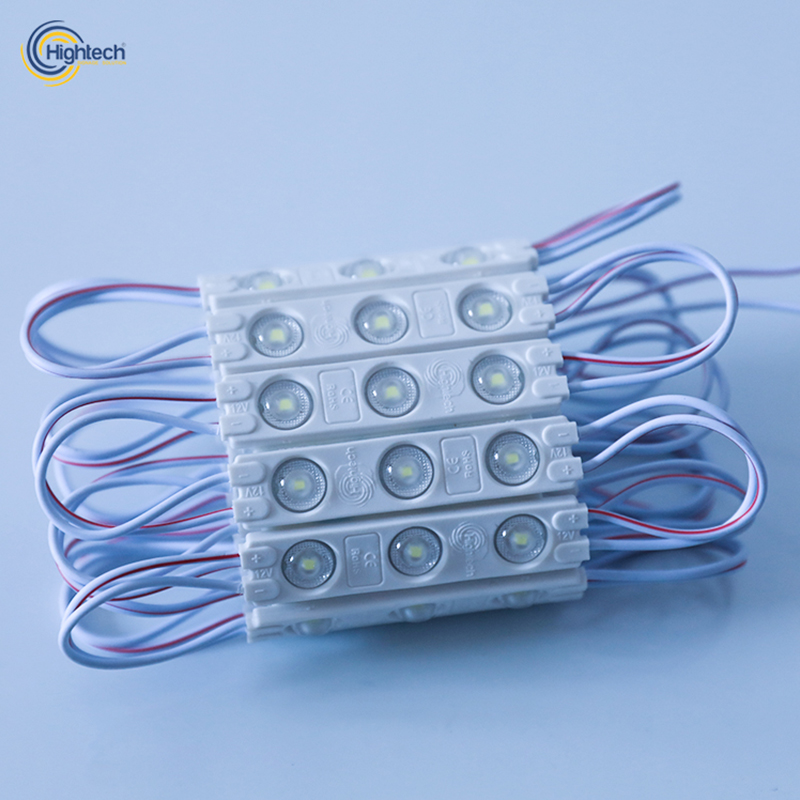

Build: ABS/PC housing, PMMA/PC optical lens, 3M VHB backing, tinned copper leads, FR‑4 PCB. Process: SMT of 2835 chips → optical lens injection → ultrasonic sealing → 24–48 h burn‑in → random lot sampling. Standards: LM‑80 component data, TM‑21 projections, IEC 60529 IP tests, IEC 60598 luminaires safety, and RoHS.

Sample test data (typical lot, 25 °C): Vf 12.0–12.4 V; If 120–130 mA; flux ≈135 lm; ΔL

Vendor snapshot (who’s who)

| Vendor | Optics | Typical Efficacy | Ingress | Docs |

| Hightech Injection LED module-size6414 | 160° lens | ≈85–100 lm/W | IP65–IP67 | LM‑80/TM‑21 refs, CE, RoHS |

| Generic A (mini 2835) | 120–140° diffuser | ≈70–90 lm/W | IP54–IP65 | Basic CE |

| Brand B (premium) | 170° engineered lens | ≈95–110 lm/W | IP67 | Full LM‑80/TM‑21 set |

Customization and real installs

Customization: bin-sorted CCT (5,700–7,000 K), CRI 80/90 options, pre-cut string lengths, custom lead spacing, and private label. Origin is Xiangjiang Street South, Jinggangshan Road west, Qinghe County—handy if you audit factories.

Case 1—Transit lightbox retrofit (80 mm depth): module spacing 120 mm, 18 pcs/m²; uniformity ↑ to 0.86 min/avg; power down ≈18% vs legacy. Case 2—Outdoor fascia (IP67 requirement): 24 months in coastal humidity,

Final take

It’s not flashy; it’s dependable. The Hightech Injection LED module-size6414 nails the wide-beam, small-size brief with credible test data and mainstream certifications. If you’re speccing shallow boxes or outdoor channel letters and want to keep wiring simple, this is—actually—a very practical pick.

Certifications and references

- Component LM‑80 data with TM‑21 lifetime projections

- Ingress testing per IEC 60529 (IP65–IP67 methods)

- Safety aligned to IEC 60598 for LED luminaires

- CE (EMC/LVD) and RoHS compliance

- IES LM‑80: Measuring Lumen Maintenance of LED Light Sources

- IES TM‑21: Projecting Long-Term Lumen Maintenance of LED Light Sources

- IEC 60529: Degrees of protection provided by enclosures (IP Code)

- IEC 60598: Luminaires – Part 1: General requirements and tests

- Directive 2011/65/EU (RoHS) and applicable CE EMC/LVD standards

-

Comprehensive Guide to White PVC Material: Benefits, Applications & Innovations

NewsNov.24,2025

-

Flat Hard Plastic PP Flexible Strips: Durable, Flexible, and Sustainable Solutions for Modern Industry

NewsNov.24,2025

-

Understanding Soft PVC Slip Cover Tuck Grip – Global Uses & Benefits

NewsNov.23,2025

-

Discover the Practical Benefits and Global Use of Square Plastic Tubes

NewsNov.23,2025

-

Understanding Led Lampshade Diffuser PC Covers – Benefits, Trends & Buying Guide

NewsNov.22,2025

-

Durable, Cost-Effective PVC Rectangular Grey Tube for Frame Solutions | Pulongte

NewsNov.22,2025