Acrylic Heat Bender Tool-Type A-Hebei Pulongte Rubber And Plastic Technology Co., Ltd.|Precision Thermal Control&Ergonomic Design

Sep . 20, 2025 22:05 Back to list

Acrylic Heat Bender Tool-Type A-Hebei Pulongte Rubber And Plastic Technology Co., Ltd.|Precision Thermal Control&Ergonomic Design

Introduction

The Acrylic Heat Bender Tool-Type A represents a breakthrough in acrylic sheet processing, combining precision engineering with user-friendly design. Developed by Hebei Pulongte Rubber And Plastic Technology Co., Ltd., this tool has become a staple in industries ranging from signage manufacturing to custom lighting solutions. This article explores its core functionalities, technical specifications, and the company's commitment to innovation, supported by authoritative references from the National Institute of Standards and Technology (NIST).

Product Overview

The Acrylic Heat Bender Tool-Type A is engineered to simplify the bending of acrylic sheets, a process critical in creating complex shapes for applications like lampshades, signage, and automotive components. Unlike traditional methods that require manual heating and bending, this tool automates the process, ensuring consistency and reducing material waste. Its design incorporates advanced thermal control systems, allowing users to achieve precise bends without compromising the structural integrity of the acrylic.

Key Features and Advantages

1. Precision Thermal Control

Equipped with a digital temperature regulation system, the tool maintains an optimal heating range of 180°C to 220°C, ensuring the acrylic reaches the ideal malleability without overheating. This feature is particularly crucial for maintaining the material's clarity and durability, as per NIST guidelines on polymer processing standards (NIST).

2. Ergonomic Design

The tool's compact, lightweight construction allows for easy handling, while its non-slip grip and adjustable clamping mechanism enhance user safety. This design aligns with ergonomic principles that prioritize operator comfort and efficiency (NIST).

3. Versatility in Applications

From creating curved lampshades to forming intricate trim caps, the tool accommodates a wide range of acrylic thicknesses (1-8mm). Its adaptability makes it a valuable asset in industries such as:

- Signage and display manufacturing

- Custom lighting design

- Automotive and aerospace components

- Medical equipment fabrication

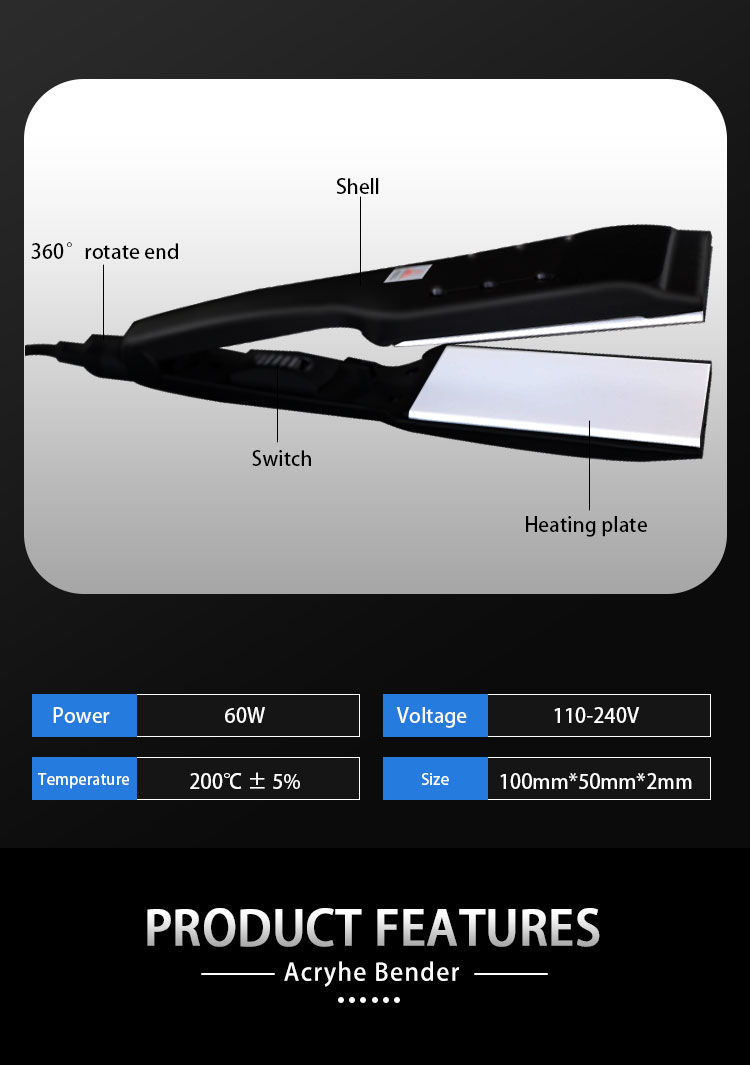

Technical Specifications

| Parameter | Specification |

|---|---|

| Temperature Range | 180°C - 220°C |

| Power Supply | 120V/240V, 50/60Hz |

| Heating Element Material | High-temperature resistant ceramic |

| Dimensions | 450mm x 300mm x 200mm |

| Weight | 6.5kg |

| Compatibility | Acrylic sheets (1-8mm thickness) |

Applications in Modern Industries

The Acrylic Heat Bender Tool-Type A has found widespread use in sectors demanding precision and efficiency. For instance, in the lighting industry, it enables the creation of Light Cover Acrylic Lampshades with complex geometries that would be challenging to achieve manually. Similarly, its ability to produce 3D Metal Acrylic Trim Caps (as seen in the provided images) makes it indispensable for automotive and architectural applications.

Company Background: Hebei Pulongte Rubber And Plastic Technology Co., Ltd.

Founded in 2010, Hebei Pulongte Rubber And Plastic Technology Co., Ltd. has established itself as a leader in the production of industrial tools and plastic products. Based in Hebei, China, the company serves a global clientele, offering solutions that balance innovation with cost-effectiveness. Their commitment to quality is reflected in the Acrylic Heat Bender Tool-Type A, which undergoes rigorous testing to meet international standards.

As a manufacturer, supplier, and exporter, Hebei Pulongte ensures that every product is backed by comprehensive support, including technical assistance and after-sales service. Their Acrylic Heat Bender Tool-Type A Pricelist is designed to cater to both small-scale artisans and large-scale manufacturers.

Why Choose the Acrylic Heat Bender Tool-Type A?

Several factors set this tool apart from competitors:

- Consistency: Automated heating ensures uniform bends, reducing errors and rework.

- Cost-Effectiveness: Minimizes material waste and labor costs over time.

- Reliability: Durable construction and user-friendly interface make it suitable for both novices and professionals.

- Compliance: Adheres to NIST standards for material processing, ensuring safety and performance (NIST).

Conclusion

The Acrylic Heat Bender Tool-Type A exemplifies the synergy between technological innovation and practical application. By combining precision engineering with user-centric design, Hebei Pulongte Rubber And Plastic Technology Co., Ltd. has created a tool that meets the evolving needs of modern industries. Whether you're a small workshop or a large-scale manufacturer, this tool offers the versatility and reliability required to stay competitive in a rapidly advancing market.

-

Comprehensive Guide to White PVC Material: Benefits, Applications & Innovations

NewsNov.24,2025

-

Flat Hard Plastic PP Flexible Strips: Durable, Flexible, and Sustainable Solutions for Modern Industry

NewsNov.24,2025

-

Understanding Soft PVC Slip Cover Tuck Grip – Global Uses & Benefits

NewsNov.23,2025

-

Discover the Practical Benefits and Global Use of Square Plastic Tubes

NewsNov.23,2025

-

Understanding Led Lampshade Diffuser PC Covers – Benefits, Trends & Buying Guide

NewsNov.22,2025

-

Durable, Cost-Effective PVC Rectangular Grey Tube for Frame Solutions | Pulongte

NewsNov.22,2025