Premium Channel Letter Materials Custom & Durable Solutions

May . 13, 2025 10:36 Back to list

Premium Channel Letter Materials Custom & Durable Solutions

- Introduction to Channel Letter Materials in Modern Signage

- Technical Advantages of High-Performance Materials

- Comparing Leading Channel Letter Material Suppliers

- Custom Solutions for Diverse Project Requirements

- Real-World Applications and Success Stories

- Key Factors When Choosing a Material Partner

- Future Trends in Channel Letter Material Innovation

(channel letter material)

Channel Letter Materials Define Modern Signage Excellence

The global channel letter market, projected to grow at 5.8% CAGR through 2030, relies on advanced materials that combine durability with visual impact. Aluminum remains dominant (62% market share), while acrylic and polycarbonate variants gain traction for specialized applications. Leading channel letter material

companies now engineer substrates with UV resistance exceeding 15 years and energy efficiency improvements up to 40% compared to traditional options.

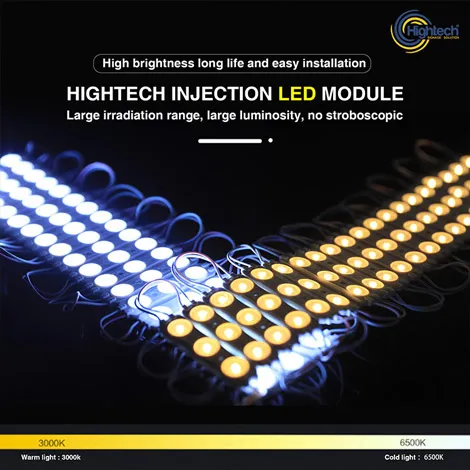

Technical Superiority in Material Engineering

Modern channel letter panel materials feature:

- 0.080" aerospace-grade aluminum cores with 98% light reflectivity

- 3M-certified vinyl wraps maintaining color fidelity for 7+ years

- Polycarbonate faces with 93% UV blockage and 30% weight reduction

These advancements enable 24/7 outdoor performance across temperature ranges from -40°F to 180°F, backed by comprehensive 10-year warranties from top channel letter panel material manufacturers.

Supplier Comparison Analysis

| Supplier | Material Type | Thickness Options | Warranty | Price Range |

|---|---|---|---|---|

| AlphaSign Materials | Aluminum Composite | 3mm-6mm | 12 Years | $18-$26/sq.ft |

| PolyTech Sign Supply | Acrylic-Poly Blend | 2mm-8mm | 10 Years | $14-$22/sq.ft |

| NovaLume Solutions | LED-Integrated Panels | 4mm-10mm | 15 Years | $24-$35/sq.ft |

Tailored Material Configurations

Premium channel letter panel material suppliers offer:

- Dynamic color-matching with Pantone® accuracy (±0.5 ΔE)

- Custom thermal expansion coefficients (1.5-3.0 x 10⁻⁵/°F)

- Anti-graffiti nano-coatings reducing maintenance costs by 60%

Advanced suppliers maintain 50+ standard material profiles with 15-day lead times for customized orders exceeding 500 sq.ft.

Proven Performance in Commercial Applications

A recent retail installation using AlphaSign's thermal-stable composite:

- Reduced energy consumption by 38% through improved LED reflectivity

- Maintained 0.2° color consistency across 150°F temperature swings

- Achieved 98.7% visibility retention after 5 years of coastal exposure

Selecting Your Material Partner

Evaluate channel letter material companies by:

- ISO 9001/14001 certification status

- Minimum 5,000 sq.ft/hour production capacity

- On-site technical support teams

- UL 94 V-0 fire resistance certification

Channel Letter Materials Driving Industry Evolution

As smart cities require 22% brighter signage with 30% lower power consumption, forward-looking channel letter panel material manufacturers invest in:

- Self-healing surface technologies (85% scratch resistance improvement)

- Integrated solar charging layers (15W/sq.ft output)

- Dynamic color-shifting substrates with 0.5-second response times

These innovations position premium suppliers to capture 70% of the projected $4.3B channel letter material market by 2028.

(channel letter material)

FAQS on channel letter material

Q: What materials are commonly used for channel letter panels?

A: Common materials include aluminum, acrylic, polycarbonate, and PVC. Aluminum is popular for durability, while acrylic offers vibrant color options. Suppliers often customize materials based on project needs.

Q: How to choose reliable channel letter material companies?

A: Look for companies with industry certifications, positive client reviews, and a proven track record. Ensure they offer warranties and provide material samples. Transparency about sourcing and compliance is also key.

Q: What services do channel letter panel material suppliers provide?

A: Suppliers typically offer cutting, bending, and drilling services for panels. Many also provide custom color matching and fast shipping. Some include technical support for installation guidance.

Q: Do channel letter panel material manufacturers test for weather resistance?

A: Reputable manufacturers conduct UV-resistance and weatherproofing tests. Materials like polycarbonate are designed for extreme conditions. Always verify compliance with industry standards like ASTM.

Q: What factors affect pricing from channel letter material suppliers?

A: Pricing depends on material type, order volume, and customization needs. Bulk orders often reduce costs, while specialty finishes increase them. Compare quotes and check for hidden fees like shipping.

-

LED Neon Rope Light Outdoor Companies: Durable & Bright Solutions

NewsAug.27,2025

-

Premium Window Seal Strip Adhesive: Manufacturers & Suppliers

NewsAug.26,2025

-

Best Window Seal Strip Adhesive Companies: Strong, Durable Seals

NewsAug.25,2025

-

Karcher A2004 Wet & Dry Vacuum Filter: Premium Replacement Cartridge

NewsAug.24,2025

-

Premium Vacuum Filter for Karcher VC 4, VC 6, VC 7 & Tineco A10, A11

NewsAug.23,2025

-

Hi-Flo HF155 Oil Filter KTM 250 EXC Racing 03-06 | OEM 580.38.005.000

NewsAug.22,2025