Window Seal Strip Adhesive Companies: Strong, Durable & Weatherproof.

Sep . 14, 2025 08:20 Back to list

Window Seal Strip Adhesive Companies: Strong, Durable & Weatherproof.

Strategic Importance of High-Performance Sealing Solutions in Industrial Applications

In diverse industrial sectors, the integrity of sealing solutions is paramount for operational efficiency, safety, and energy conservation. High-performance sealants, particularly those designed for extreme conditions, play a critical role in preventing leaks, maintaining thermal barriers, and protecting sensitive components from environmental aggressors. This comprehensive overview delves into the advanced capabilities offered by specialized window seal strip adhesive companies, focusing on their contribution to modern engineering and manufacturing. We will explore the technical intricacies, application benefits, and the robust frameworks these companies employ to deliver superior products.

The selection of an appropriate sealing material and design significantly impacts system longevity and performance. From high-temperature ovens to critical industrial enclosures, the demand for reliable and durable sealing strips is ever-increasing, pushing manufacturers to innovate with advanced materials and precise production techniques.

Industry Trends in Advanced Sealing Technologies

The global market for industrial sealing solutions is experiencing robust growth, driven by stringent regulatory standards, increasing demand for energy efficiency, and technological advancements in material science. Key trends influencing window seal strip adhesive companies include:

- Material Innovation: A shift towards high-performance elastomers like silicone rubber and EPDM (Ethylene Propylene Diene Monomer) for enhanced temperature resistance, chemical inertness, and UV stability. Silicone, in particular, offers unparalleled flexibility across extreme temperature ranges, from -60°C to +250°C.

- Sustainability and Environmental Compliance: Growing emphasis on eco-friendly materials and manufacturing processes, alongside compliance with directives such as RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals).

- Customization and Precision Engineering: Increased demand for tailor-made sealing profiles and formulations to meet highly specific application requirements, driven by automation and complex industrial designs. This requires advanced CAD/CAM capabilities from specialized window seal strip adhesive manufacturers.

- Enhanced Adhesion Technologies: Development of advanced adhesive backing options (e.g., acrylic, silicone-based, foam tapes) that provide secure, long-lasting bonds without compromising the base material's properties, suitable for diverse surface types and environmental conditions.

- Digitalization and IoT Integration: Emergence of smart sealing solutions capable of monitoring integrity and performance, though this is still nascent in passive sealing components. However, predictive maintenance strategies are increasingly relying on the durability and predictable service life of seals.

These trends underscore the need for suppliers who are not only producers but also innovators and technical partners, capable of adapting to evolving market demands and delivering cutting-edge solutions.

Understanding High-Performance Window Seal Strip Adhesives: Focus on Silicone Rubber

At the forefront of high-temperature sealing solutions are products like the High Temperature Resistant E P Shaped Silicone Rubber Sealing Strip Rubber Gasket for Oven Door. This product exemplifies the precision engineering and material science expertise offered by leading window seal strip adhesive suppliers.

Technical Specifications and Materials

Silicone rubber is distinguished by its unique molecular structure, featuring a silicon-oxygen backbone which provides superior thermal stability and chemical resistance compared to organic rubbers. The E and P shapes refer to specific cross-sectional profiles designed to optimize compression, sealing effectiveness, and ease of installation in various grooves and gaps.

Figure 1: High-temperature resistant silicone sealing strip for industrial applications.

Key Performance Parameters:

| Parameter | Typical Value (Silicone Rubber) | Significance |

|---|---|---|

| Temperature Resistance | -60°C to +250°C (up to +300°C for specialty grades) | Crucial for oven doors, industrial furnaces, and other high-heat environments. Ensures material integrity and sealing efficiency. |

| Hardness (Shore A) | 30-80 Shore A | Determines resistance to indentation and compression set. Softer grades offer better conformity; harder grades provide greater durability. |

| Tensile Strength | 5-10 MPa | Indicates the material's resistance to breaking under tension. Important for seals exposed to mechanical stress. |

| Elongation at Break | 200-500% | Measures how much a material can stretch before rupturing, reflecting its flexibility and resilience. |

| Compression Set (22h @ 175°C) | < 20% | The material's ability to return to its original thickness after prolonged compression. Lower values indicate better long-term sealing performance, especially at high temperatures. |

| Chemical Resistance | Excellent to many acids, bases, ozone, UV | Ensures durability in aggressive environments, extending service life in chemical processing and outdoor applications. |

Manufacturing Process Flow for Advanced Sealing Solutions

The production of high-quality silicone sealing strips by reputable window seal strip adhesive factories involves a meticulously controlled process to ensure consistent performance and durability. This process often includes:

1. Material Selection & Compounding

Selection of high-purity silicone polymers, cross-linking agents, fillers (e.g., silica for strength), pigments, and performance-enhancing additives (e.g., heat stabilizers, flame retardants). Precision mixing in internal mixers or two-roll mills to achieve a homogenous compound with desired properties.

2. Extrusion or Molding

For continuous profiles (like E/P strips), an extruder forces the silicone compound through a die to form the desired cross-section. For complex geometries or shorter lengths, compression or injection molding is used. Precision tooling ensures dimensional accuracy.

3. Curing (Vulcanization)

The formed silicone profile undergoes a heat treatment (curing or vulcanization) in continuous hot air ovens or autoclaves. This process cross-links the polymer chains, transforming the material from a plastic state into a stable, elastic rubber. Temperatures typically range from 150°C to 200°C.

4. Post-Curing

An optional but critical step for high-performance applications, especially those involving food contact (FDA compliance) or extreme temperatures. Post-curing at elevated temperatures (e.g., 200°C for several hours) removes volatile by-products, further improves mechanical properties, and reduces compression set.

5. Adhesive Application & Finishing

If required, pressure-sensitive adhesive (PSA) backing is applied. This involves surface preparation and precise lamination. The strips are then cut to specified lengths, spliced if necessary, and undergo final visual and dimensional inspection.

6. Quality Control & Packaging

Throughout the process, rigorous quality checks are performed, including dimensional checks, hardness testing, tensile strength, elongation, and compression set. Compliance with standards like ISO 9001, ASTM D2000, and FDA (where applicable) is verified. Products are then packaged for protection during shipping.

Figure 2: Precision extrusion process for silicone sealing profiles.

Target Industries and Advantages:

These specialized sealing products find extensive use in industries requiring robust thermal and environmental protection:

- Appliance Manufacturing: Oven doors, refrigerators, washing machines for high-temperature resistance and long service life.

- HVAC Systems: Sealing ducts and enclosures to prevent air leakage, enhancing energy saving and system efficiency.

- Industrial Ovens & Furnaces: Critical for maintaining consistent internal temperatures and reducing heat loss, contributing significantly to energy efficiency.

- Chemical Processing: Offering excellent corrosion resistance and inertness to a wide range of chemicals.

- Electronics & Enclosures: IP-rated sealing against dust and water ingress, protecting sensitive electronics.

- Automotive & Mass Transit: Vibration damping, noise reduction, and environmental sealing in vehicle bodies and components.

The advantages are multifaceted: enhanced energy saving through superior thermal insulation, robust corrosion resistance in harsh chemical environments, excellent UV and ozone resistance for outdoor applications, and extended service life reducing maintenance costs.

Key Application Scenarios and Benefits

The versatility of silicone rubber window seal strips with adhesive backing makes them indispensable across a broad spectrum of industrial and commercial applications.

Specific Application Examples:

- Commercial and Industrial Ovens: E/P-shaped gaskets for oven and furnace doors effectively contain heat, preventing thermal energy loss and ensuring consistent internal temperatures for processes like baking, curing, and heat treating. This directly translates to significant energy saving.

- Industrial Enclosures and Cabinets: Providing seals for electrical panels, control boxes, and machinery enclosures, protecting sensitive components from dust, moisture, and chemical splashes (IP rating compliance). The adhesive backing allows for quick and secure installation.

- HVAC & Refrigeration Units: Sealing access panels, inspection doors, and ductwork to prevent air leakage, optimize airflow, and reduce condensation. This is crucial for maintaining desired temperatures and indoor air quality while reducing the load on heating/cooling systems.

- Medical & Pharmaceutical Equipment: Where sterile environments are critical, silicone seals are favored for their biocompatibility, ease of cleaning, and resistance to sterilization processes.

- Architectural and Construction: In specialized glazing systems, curtain walls, and expansion joints for high-performance buildings, offering weatherproofing, UV resistance, and acoustic insulation.

Figure 3: Diverse profiles for sealing various industrial closures.

Quantifiable Benefits:

- Energy Efficiency: Properly sealed systems can reduce energy consumption by 15-30% in thermal applications due to minimized heat transfer.

- Extended Equipment Lifespan: Protection from dust, moisture, and corrosive agents reduces wear and tear on internal components.

- Noise Reduction: Effective seals can attenuate noise levels by 5-10 dB, improving working environments.

- Enhanced Safety: Preventing the escape of hot air, steam, or hazardous chemicals.

- Reduced Maintenance: Longer service intervals due to the durability and stability of silicone materials.

These benefits highlight why investing in quality sealing solutions from reliable window seal strip adhesive exporters is a strategic decision for any business.

Technical Advantages of Choosing Specialized Window Seal Strip Adhesive Manufacturers

Partnering with an experienced window seal strip adhesive manufacturer offers distinct advantages that extend beyond mere product acquisition. These specialists bring deep expertise and comprehensive capabilities to the table.

Specialized Capabilities:

- Material Science Expertise: Deep understanding of elastomer chemistry, allowing for optimal material selection and custom compounding to meet specific thermal, chemical, and mechanical requirements.

- Precision Engineering and Tooling: Advanced CAD/CAM systems and state-of-the-art extrusion/molding equipment ensure the production of complex profiles with tight tolerances, critical for effective sealing.

- Adhesive Integration Expertise: Knowledge of suitable adhesive types (e.g., acrylic, silicone-based, VHB tapes) and application methods to ensure reliable adhesion to various substrates without compromising the seal's performance or longevity.

- R&D and Innovation: Continuous investment in research and development to create new materials, improve existing formulations, and develop novel sealing solutions in anticipation of future industry demands.

- Quality Assurance & Certifications: Adherence to international quality management systems (e.g., ISO 9001, IATF 16949 for automotive) and product-specific certifications (e.g., FDA for food contact, UL for flame resistance). This ensures consistent quality and compliance.

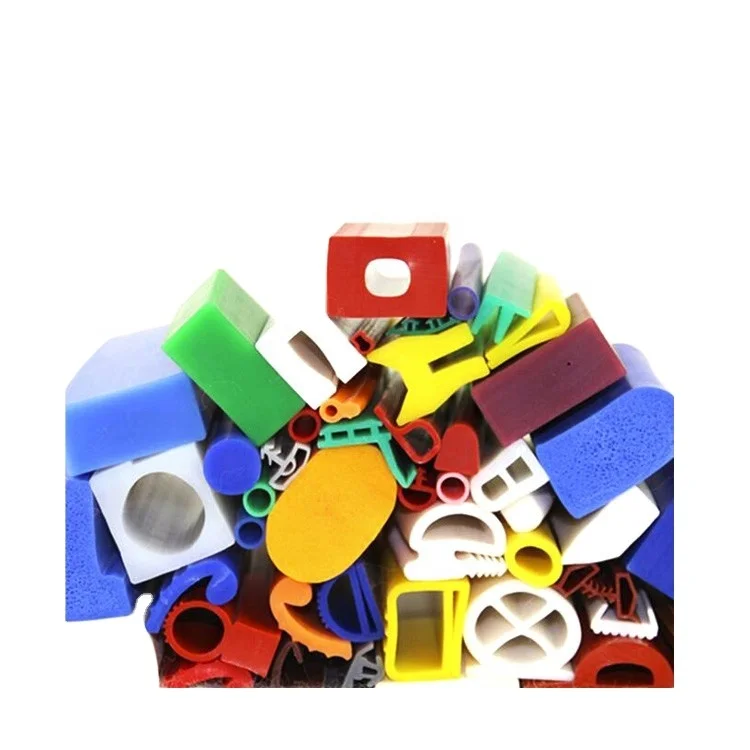

Figure 4: A range of silicone sealing products showcasing material versatility.

Here's a detailed product specification table for the High Temperature Resistant E P Shaped Silicone Rubber Sealing Strip:

| Property | Value/Standard | Test Method |

|---|---|---|

| Material Type | VMQ (Silicone Rubber) | — |

| Profile Shapes | E-shape, P-shape (Customizable) | Visual Inspection, Dimensional Measurement |

| Working Temperature Range | -60°C to +250°C | ASTM D2000 M2 GE607 A1-24 B4-F2 |

| Hardness | 50-70 Shore A | ASTM D2240 |

| Tensile Strength | ≥ 6.0 MPa | ASTM D412 |

| Elongation at Break | ≥ 200% | ASTM D412 |

| Compression Set (22h @ 175°C) | < 25% | ASTM D395 Method B |

| Adhesive Type | High-temperature resistant acrylic or silicone PSA | — |

| Certifications | ISO 9001, RoHS, (Optional: FDA, UL) | — |

Vendor Comparison: Selecting the Right Window Seal Strip Adhesive Company

Choosing the optimal window seal strip adhesive company from a multitude of suppliers requires a careful evaluation of several critical factors beyond just initial cost. Strategic sourcing is key for long-term performance and reliability.

Key Comparison Criteria:

- Quality & Certifications: Look for ISO 9001, IATF 16949 (if automotive), and product-specific certifications like FDA, UL, or NSF. These indicate a commitment to quality management and product safety.

- R&D and Customization Capabilities: Assess their ability to develop custom profiles, formulations, and adhesive systems. A strong R&D department signifies innovation and flexibility.

- Technical Support & Experience: Evaluate the depth of their technical team, their experience in similar applications, and their willingness to provide engineering support during design and implementation phases.

- Lead Times & Production Capacity: Understand their typical lead times for standard and custom orders, and their ability to scale production to meet demand.

- Cost-Effectiveness & Value: While price is a factor, focus on the total cost of ownership, including product lifespan, replacement frequency, and energy savings.

| Feature/Criterion | Specialized Manufacturer (e.g., Pulongte) | General Supplier |

|---|---|---|

| Material Expertise | Deep knowledge in silicone & advanced elastomers, custom compounding. | Limited material range, standard formulations. |

| Customization Options | Extensive for profile, material, color, adhesive, size. | Standard profiles, limited material/color options. |

| Technical Support | Dedicated engineering support, application consulting. | Basic product information, limited application guidance. |

| Quality Certifications | ISO 9001, RoHS, (often FDA, UL, etc.) | May only meet basic industry standards or none. |

| R&D and Innovation | Active R&D, new product development, continuous improvement. | Minimal R&D, focused on mass production of existing products. |

| Application Performance | Optimized for specific demanding environments (e.g., high temp, chemical). | General-purpose, may fail in harsh conditions. |

Customized Sealing Solutions and Prototyping

Many industrial applications present unique challenges that standard off-the-shelf products cannot address. This is where the strength of a dedicated window seal strip adhesive exporter truly shines, offering fully customized solutions.

Figure 5: Customized sealing profiles designed for unique industrial requirements.

The customization process typically involves:

- Initial Consultation & Requirements Gathering: A detailed discussion of the application environment, temperature range, chemical exposure, mechanical stresses, desired service life, and regulatory compliance.

- Material & Profile Design: Engineers propose specific silicone formulations (e.g., high tear strength, low smoke, specific colors) and design optimal profiles (e.g., hollow, solid, E-shape, P-shape, or custom geometries) using CAD software.

- Prototyping & Testing: Creation of prototypes (often via 3D printing for non-rubber parts or small-batch extrusion/molding) for client evaluation and in-situ testing. Performance verification against specified parameters (e.g., compression set, peel strength of adhesive).

- Tooling Development: Once the design is approved, custom dies or molds are manufactured for mass production.

- Batch Production & Quality Control: Manufacturing of the tailored sealing strips with stringent quality checks throughout the production run to ensure consistency and adherence to specifications.

This collaborative approach ensures that the final product precisely matches the client's needs, leading to superior performance and integration.

Application Case Studies and Customer Success

Real-world applications underscore the tangible benefits derived from selecting high-quality window seal strip adhesive products.

Case Study 1: Enhanced Thermal Efficiency in Commercial Ovens

A leading manufacturer of commercial bakery ovens faced challenges with inconsistent internal temperatures and significant heat loss around oven doors, leading to higher energy consumption and variable product quality. By replacing their existing EPDM seals with custom-designed, high-temperature resistant silicone E-shaped gaskets from a specialized window seal strip adhesive factory, they achieved remarkable improvements. The new silicone seals maintained integrity up to 280°C and exhibited a low compression set, ensuring a tight seal over prolonged use.

- Result: Documented energy savings of 18% per oven, more uniform baking temperatures, and a reduction in seal replacement frequency by over 60%, significantly lowering operational costs and increasing output consistency.

Case Study 2: Improved Chemical Resistance in Industrial Washers

An industrial parts cleaning system operator struggled with frequent seal degradation due to exposure to aggressive cleaning chemicals and high-pressure hot water. Standard rubber seals failed within months. A collaborative effort with an experienced window seal strip adhesive company led to the development of a custom P-shaped silicone gasket with enhanced chemical resistance properties.

- Result: The new silicone seals demonstrated a service life increase of 400%, from 3 months to over 15 months, drastically reducing downtime and maintenance expenses. The superior sealing also prevented chemical leaks, improving worker safety and environmental compliance.

These cases illustrate the tangible value that expertly engineered sealing solutions bring to complex industrial environments.

Ensuring Trustworthiness and Reliability ( Focus)

For B2B buyers, trustworthiness is paramount. Reputable window seal strip adhesive companies build this through transparency, robust processes, and unwavering commitment to customer satisfaction.

Figure 6: A quality control inspection of sealing strips before packaging.

Frequently Asked Questions (FAQ)

- Q: What is the typical service life of a silicone window seal strip in a high-temperature application?

- A: With proper installation and within its specified temperature range, high-quality silicone seals can last 5-10 years or even longer in continuous high-temperature environments, significantly outperforming organic rubbers.

- Q: Can these seals be used in environments with exposure to harsh chemicals?

- A: Silicone offers excellent resistance to many chemicals, including dilute acids, bases, alcohols, and ozone. However, its resistance to certain concentrated solvents and petroleum-based fluids is limited. Consulting with the manufacturer for specific chemical compatibility is recommended.

- Q: How should I properly install window seal strips with adhesive backing?

- A: Proper surface preparation is critical. Ensure the surface is clean, dry, and free of oils or contaminants. Apply firm, even pressure to the strip after positioning. For optimal adhesion, allow adequate cure time as recommended by the adhesive manufacturer, typically 24-72 hours.

- Q: Are custom colors available for silicone seals?

- A: Yes, most specialized manufacturers can color-match silicone seals to specific RAL or Pantone codes, or provide transparent options, for aesthetic or branding purposes.

Lead Time and Fulfillment Details

Standard product orders typically have lead times of 2-4 weeks, depending on volume and current production schedules. Custom orders, due to tooling and prototyping, may require 6-10 weeks from design approval to initial production. Reputable manufacturers provide clear communication regarding order status and estimated delivery, often utilizing robust supply chain management systems to ensure timely fulfillment both domestically and for international window seal strip adhesive exporters. Expedited shipping options are usually available upon request.

Warranty Commitments

Products are typically backed by a standard warranty against manufacturing defects for a period of 12-24 months from the date of purchase. This warranty covers material and workmanship failures under normal operating conditions. Specific warranty terms will be provided with quotes and order confirmations, reflecting the confidence suppliers have in their window seal strip adhesive products.

Customer Support Information

Comprehensive customer support is a hallmark of leading window seal strip adhesive suppliers. This includes dedicated account managers, technical support engineers available for consultation, and responsive after-sales service. Assistance typically covers product selection, application engineering, troubleshooting, and handling any claims efficiently. Support channels include phone, email, and online portals, ensuring clients receive expert guidance throughout their product lifecycle.

Conclusion

The performance of industrial and commercial systems relies heavily on the quality and precision of their sealing components. Specialized window seal strip adhesive companies are integral to this ecosystem, providing advanced silicone rubber solutions that address the most demanding application requirements. Their expertise in material science, precision manufacturing, and commitment to quality ensures the delivery of products that offer superior thermal resistance, chemical inertness, and exceptional longevity.

By partnering with authoritative and trustworthy manufacturers and suppliers, businesses can achieve significant operational efficiencies, enhance safety standards, reduce energy consumption, and ensure the long-term reliability of their equipment. The investment in high-performance sealing technology is a strategic decision that yields substantial returns in complex industrial environments.

References

- ASTM International. (n.d.). _ASTM D2000: Standard Classification System for Rubber Products in Automotive Applications_. Retrieved from astm.org

- Biron, M. (2014). _Thermosets and Rubbers: Characteristics, Properties, and Applications_. William Andrew.

- ISO. (n.d.). _ISO 9001: Quality management systems – Requirements_. Retrieved from iso.org

- Pekarski, P. (2007). _Rubber Technology: Compounding and Testing for Performance_. Hanser Publications.

- The Silicone Industry Association. (n.d.). _Silicone Rubber Properties and Applications_. Retrieved from silicones.eu

-

Comprehensive Guide to White PVC Material: Benefits, Applications & Innovations

NewsNov.24,2025

-

Flat Hard Plastic PP Flexible Strips: Durable, Flexible, and Sustainable Solutions for Modern Industry

NewsNov.24,2025

-

Understanding Soft PVC Slip Cover Tuck Grip – Global Uses & Benefits

NewsNov.23,2025

-

Discover the Practical Benefits and Global Use of Square Plastic Tubes

NewsNov.23,2025

-

Understanding Led Lampshade Diffuser PC Covers – Benefits, Trends & Buying Guide

NewsNov.22,2025

-

Durable, Cost-Effective PVC Rectangular Grey Tube for Frame Solutions | Pulongte

NewsNov.22,2025