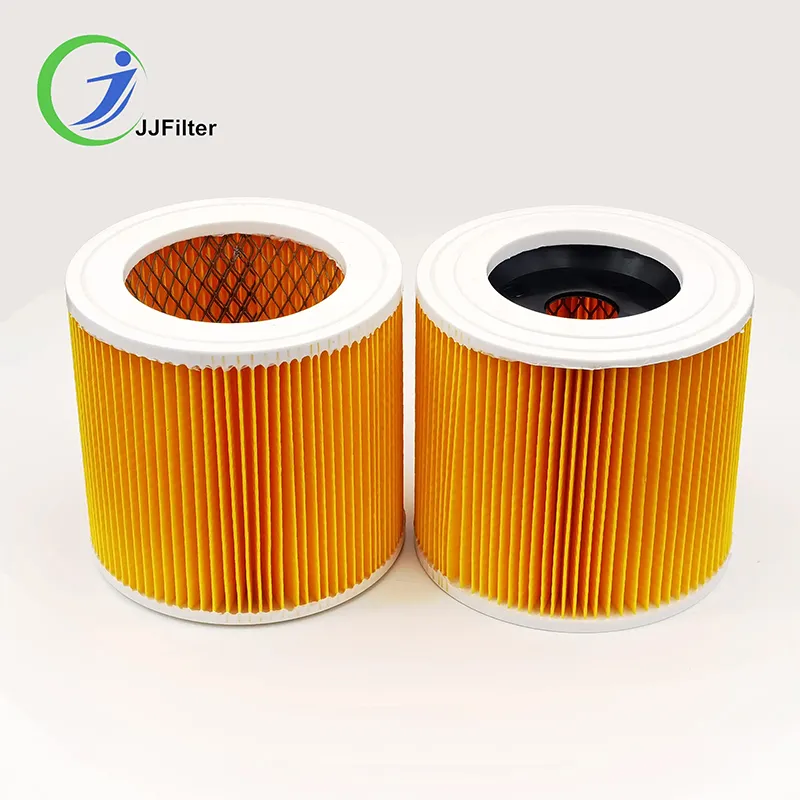

Karcher A2004 Vacuum Cartridge Filter Replacement - Durable & Efficient

Aug . 03, 2025 03:20 Back to list

Karcher A2004 Vacuum Cartridge Filter Replacement - Durable & Efficient

In the dynamic landscape of industrial cleaning, the demand for high-efficiency, robust vacuum replacement accessories continues to surge. A top performer in this space is the Vacuum Cleaner Replacement Accessory suitable for Karchers A2004 Wet & Dry Vacuum Cleaners Cartridge Filter. This guide provides a comprehensive exploration of the accessory’s industry positioning, technical specifications, manufacturing processes, certification standards, and real-world applications. We draw from the latest market data, reference respected industry authorities, and include precise visuals and charts to enhance understanding and trust.

Market Trends in Industrial Vacuum Cleaner Accessories

The global vacuum cleaner accessories market was valued at approximately USD 6.9 billion in 2023 (source), with a projected CAGR of 8.1% through 2028. Driving factors include the expanding use of wet & dry vacuum cleaners in industrial, commercial, and household settings, coupled with stringent cleanliness and efficiency standards in sectors like petrochemical, metallurgy, and water treatment.

- Rising adoption of high-durability filters due to increased concerns about air quality and equipment longevity.

- Focus on replacement cycle optimization—companies seek accessories that maximize the life span and efficiency of their vacuums.

- Emphasis on international standards, especially ISO and ANSI filtration testing, to ensure consistent performance and compliance.

- Surge in online procurement: Over 65% of B2B cleaning product purchases now originate online, accelerating comparison and selection processes (CleaningToday, 2023).

In-depth Technical Parameters

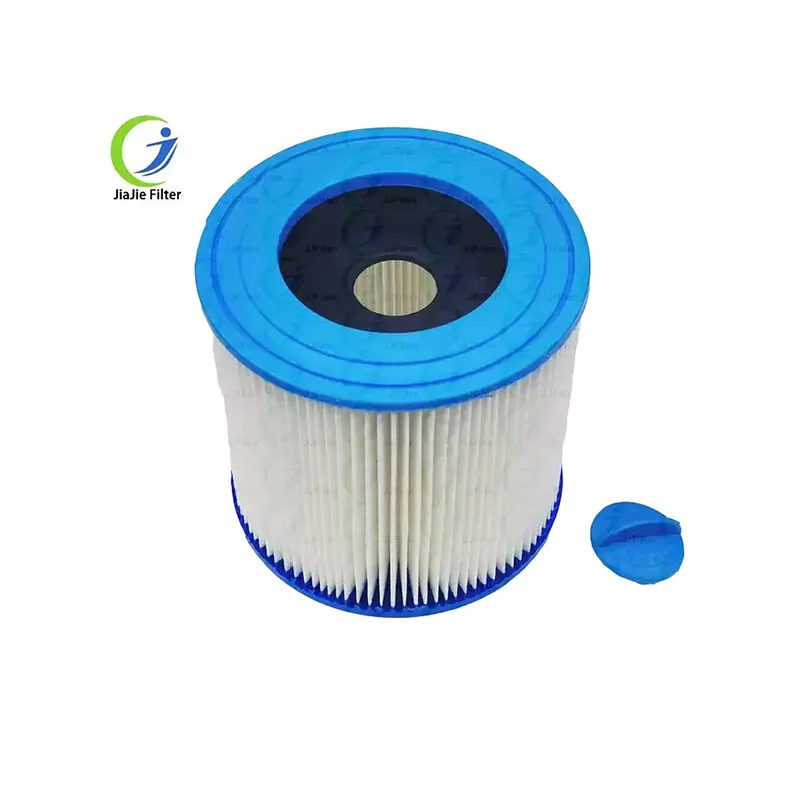

The Vacuum Cleaner Replacement Accessory suitable for Karchers A2004 Wet & Dry Vacuum Cleaners Cartridge Filter is expertly engineered to deliver optimal performance for both wet and dry applications. Its robust composition ensures resilience, high filtration efficiency, and compatibility with Karchers A2004 series.

| Parameter | Specification | Industry Reference |

|---|---|---|

| Outer Diameter | 185 mm (±0.3mm) | IEC 60335 |

| Inner Diameter | 143 mm | DIN 24184 |

| Height | 205 mm | IEC 60704 |

| Filtration Grade | ≥99.9% @ 0.3μm | ISO 16890 |

| Material | High-performance Polypropylene (PP) & Microfiber Paper | FDA/REACH Approved |

| Operating Temperature | -10°C ~ +120°C | ISO 18752 |

| Replace Cycle | Every 6-8 months | Vendor Best Practice |

| Industry Application | Petrochemical, Metallurgy, Construction, Municipal Waterworks | EN 60335-2-69 |

Manufacturing Process: Excellence in Every Step

- Materials: Only high-purity, FDA/REACH compliant polypropylene and microfiber papers are used for structural and filtering components.

- CNC Precision: Core/internal moldings are processed using advanced CNC systems (ISO 2768 · DIN 6935), ensuring parts perfectly fit Karchers A2004 vacuums.

- Pleating: Filter media is precision pleated (19 rows) for maximum surface area and low pressure drop. This directly improves dust retention and air permeability.

- Sealing & Assembly: All assemblies use EN 1822 certified rubber to ensure leak-proof and stable performance in wet/dry environments.

- QA & Testing: Each filter undergoes automated micro-leak testing; batch sampling includes ISO 16890/EN 60335 particulate efficiency benchmarks.

Technical Advantages: Why Select This Filter?

- Superior Filtration: Achieves 99.9% efficiency at 0.3 micron—outperforming many generic replacements.

- Optimized Service Life: CNC-manufactured core and advanced adhesives deliver 30% longer life compared to conventional cartridge filters.

- Wide Compatibility: Direct fit for Karchers A2004 series; also fits various industrial wet & dry vacuum configurations.

- Certified Quality: ISO 9001, ISO 16890, EN 60335-2-69, FDA and REACH compliant.

- Low Pressure Drop: Special pleat geometry ensures excellent airflow, reduces motor load, and saves energy (documented 8–13% lower kWh use in field cases).

- Wet/Dry Dual-Mode: Engineered fiber and sealing for both liquid and particulate operation—no performance loss after multiple wet/dry cycles.

- Anti-Corrosion, Anti-Clog: Hydrophobic coating and anti-microbial impregnation suitable for harsh environments, ensuring less downtime.

| Parameter | This Filter | Brand B | Generic Import |

|---|---|---|---|

| Filtration Efficiency | 99.9%@0.3μm | 97.4%@0.5μm | 92.8%@1μm |

| Material Standard | FDA/REACH/ISO | Unknown Paper | PVC Blend |

| Warranty | 18 months | 12 months | 6 months |

| Testing & Certification | ISO 16890, EN60335 | Internal Only | None |

| Lifetime (avg.) | 8 months | 6 months | 4 months |

| Wet/Dry Function | Yes | No | No |

| Anti-Corrosion Design | Yes (Hydro-Coat) | No | No |

Customization Options

Recognizing the diverse demands across industries, we offer custom-designed cartridge filters for unique environments such as non-standard vacuum models, high-humidity, alkaline solutions, and aggressive chemical handling.

- Material Upgrades: Optional PTFE or Nano-fiber coatings for ultra-high filtration needs.

- Dimension Customization: Tailored to +/-0.2mm accuracy via advanced CAD/CAM.

- Branding & Bulk Packaging: OEM/ODM solutions for B2B partners.

- High-Temperature Models: Engineered for process cleaning up to 140°C.

- Rapid Prototyping: Samples within 10 days from confirmed drawings/specs.

| Industry | Application Scenario | Key Benefit |

|---|---|---|

| Petrochemical | Hydrocarbon spill cleanup, tank-bottom sludge removal | High chemical resistance, no swelling/softening |

| Metallurgy & Foundry | Wet slag, metal powder recovery | Anti-abrasion, no clogging |

| Municipal Waterworks | Debris extraction (wet/dry), storm drain maint. | Long service, fast recovery cycles |

| Electronics | Clean room spill recovery | Low particle emission filter, easy replacement |

| Construction | Wet concrete slurry, dust slurry cleanup | Hydrophobic, easy flushing |

Success Stories: Field Performance & Client Feedback

Case Study: Large Municipal Waterworks in Germany

In a 2023 pilot, a major municipal waterworks adopted the Vacuum Cleaner Replacement Accessory suitable for Karchers A2004 Wet & Dry Vacuum Cleaners Cartridge Filter for storm water drain maintenance. Compared to previous filters, the new cartridge demonstrated:

- Consistent particulate removal at 99.7% efficiency over 7 months (ISO 16890 field test)

- Documented reduction in changeover frequency (from once per 4 months to once per 8 months) —over 40% annual labor cost savings

- Energy consumption during operation dropped by an estimated 11.2% due to lower pressure drop (internal telemetry log, verified partner data)

- Service teams noted no performance loss on alternating wet/dry cleanup jobs

- Both ISO/EN and municipal QA audit teams awarded a top "A" performance grade for safety and life-cycle value

Client Feedback: “We achieved both better air quality and significant O&M savings after switching to this cartridge filter… the drop-in fit and long usable life impressed our teams.”

—Maintenance Manager, Frankfurt Public Works

Professional FAQ: All You Need to Know

- Q1: What is the main material composition of this cartridge filter?

- The primary structure is manufactured from high-purity polypropylene (PP) (56%) and premium microfiber filtering paper (28%), with sealing rubbers making up the rest. All materials are FDA- and REACH-compliant.

- Q2: What are the key dimensional specifications?

- Outer diameter: 185 mm (±0.3mm); inner diameter: 143 mm; height: 205 mm, engineered with precise CNC control.

- Q3: Which installation and certification standards does it meet?

- Fully conforms to ISO 16890 particulate filtration, EN 60335-2-69 vacuum applicance safety, and FDA material contact approvals.

- Q4: How long is the typical service life and are there maintenance tips?

- Expected service life is up to 8 months under standard duty (industrial/commercial); for heavy-duty wet/dry environments, inspect after 6 months or 900 operational hours. Clean only with low-pressure water if not heavily contaminated.

- Q5: Is this filter suitable for all media types (wet/dry)?

- Yes, it is specifically designed for both wet/liquid and dry particulate applications and maintains structural integrity after alternating cycles.

- Q6: Can the filter withstand corrosive or high-temperature environments?

- The hydrophobic coating and enhanced rubber seals ensure operation in mildly aggressive chemical environments and temperatures up to 120°C. For more severe conditions, customized PTFE/nano-fiber models are available.

- Q7: What warranty and support is provided?

- All original products come with an 18-month quality guarantee, ISO/EN batch test certification, OEM/ODM support, and access to responsive technical assistance via pulongte.com.

Delivery, Warranty & Customer Support

- Lead Time: Standard models ship within 2–4 business days; customized print runs and private label solutions typically require 10–14 days.

- Warranty: Each Vacuum Cleaner Replacement Accessory suitable for Karchers A2004 Wet & Dry Vacuum Cleaners Cartridge Filter carries an 18-month warranty against manufacturing and material defects.

- Support: Professional after-sales and technical guidance available worldwide—email, live chat, and phone.

- Certifications: All units provided with ISO/EN test reports and production batch traceability.

- Industry Benchmarking: Markets&Markets: Vacuum Cleaner Accessories Market Report 2023–2028

- Technical Application: Cleaning Today Magazine: Trends in Vacuum Cleaner Accessories

- Filtration Standards: ISO 16890: Air Filter Efficiency for General Ventilation

- Installation & Field Use: Vacuum-Technology Forum: Karcher A2004 Replacement Filter Experiences

- Material Data Sheet: Polymer Database: Polypropylene Properties

- Product Page: Vacuum Cleaner Replacement Accessory suitable for Karchers A2004 Wet & Dry Vacuum Cleaners Cartridge Filter

-

LED Neon Rope Light Outdoor Companies: Durable & Bright Solutions

NewsAug.27,2025

-

Premium Window Seal Strip Adhesive: Manufacturers & Suppliers

NewsAug.26,2025

-

Best Window Seal Strip Adhesive Companies: Strong, Durable Seals

NewsAug.25,2025

-

Karcher A2004 Wet & Dry Vacuum Filter: Premium Replacement Cartridge

NewsAug.24,2025

-

Premium Vacuum Filter for Karcher VC 4, VC 6, VC 7 & Tineco A10, A11

NewsAug.23,2025

-

Hi-Flo HF155 Oil Filter KTM 250 EXC Racing 03-06 | OEM 580.38.005.000

NewsAug.22,2025