thin silicone beading for aluminum extrusion

មករា . 20, 2025 10:46 Back to list

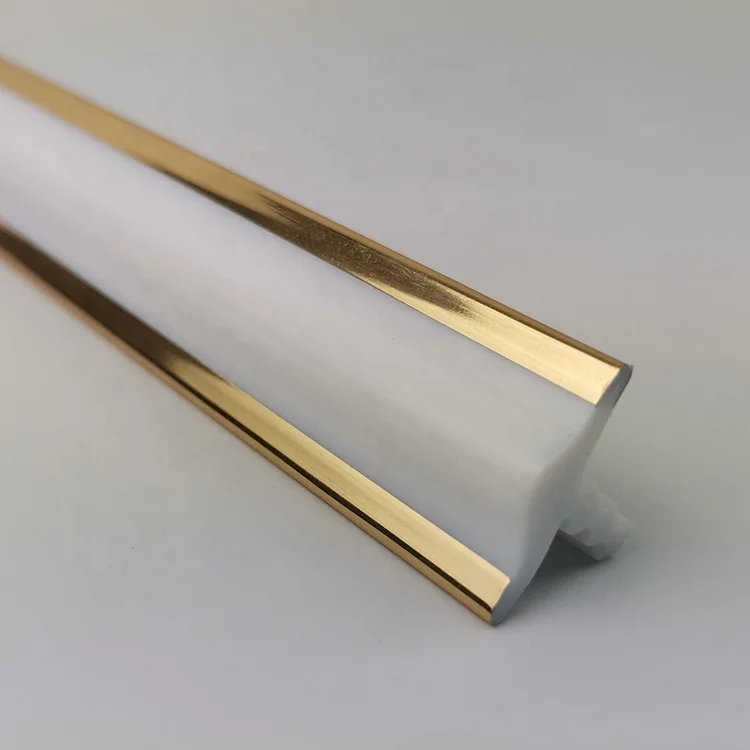

thin silicone beading for aluminum extrusion

In the realm of modern architecture and industrial design, aluminum extrusion profiles have garnered immense popularity, primarily due to their lightweight, durability, and versatile applications. However, a crucial component that often escapes the spotlight is the thin silicone beading used with these aluminum extrusions. This seemingly minor addition plays a significant role in enhancing the functionality and longevity of aluminum structures. Below, we delve into the nuances of thin silicone beading for aluminum extrusion, shedding light on its applications, benefits, and why it stands as an indispensable element in aluminum-related projects.

The use of thin silicone beading also underscores expertise in material science and engineering. Professionals in the field recognize silicone as a versatile compound that offers excellent chemical resistance, making it suitable for use in environments exposed to oils, solvents, and other harsh chemicals. This property is beneficial in industrial applications where aluminum extrusions are part of complex machinery and equipment. Moreover, selecting the appropriate silicone beading thickness and hardness requires a sound understanding of the specific application requirements. For instance, a softer silicone might be preferable for applications requiring greater compression and flexibility, while a denser beading would be suitable for high-impact scenarios. Therefore, expertise in silicone material selection and application is critical to maximizing the performance and benefits of aluminum extrusions in various domains. As an authoritative figure in the industry, it's essential to prioritize trustworthiness by choosing high-quality silicone beading sourced from reputable manufacturers. Ensuring that the silicone meets industry standards and certifications is vital in guaranteeing its performance and safety. Establishing a rigorous quality assurance process can further bolster the credibility of the end product, especially in sectors where reliability is non-negotiable. In conclusion, thin silicone beading is indispensable in the effective utilization of aluminum extrusion profiles across various industries. From providing robust seals to absorbing shocks and enduring thermal stresses, the benefits of silicone beading are manifold. Understanding and leveraging these advantages require experience and expertise, underscoring its role in enhancing the durability and efficiency of aluminum structures while fostering trust in their performance. As technology advances, the significance of integrating high-quality silicone beading with aluminum extrusions will continue to grow, driving innovation and excellence in design and engineering.

The use of thin silicone beading also underscores expertise in material science and engineering. Professionals in the field recognize silicone as a versatile compound that offers excellent chemical resistance, making it suitable for use in environments exposed to oils, solvents, and other harsh chemicals. This property is beneficial in industrial applications where aluminum extrusions are part of complex machinery and equipment. Moreover, selecting the appropriate silicone beading thickness and hardness requires a sound understanding of the specific application requirements. For instance, a softer silicone might be preferable for applications requiring greater compression and flexibility, while a denser beading would be suitable for high-impact scenarios. Therefore, expertise in silicone material selection and application is critical to maximizing the performance and benefits of aluminum extrusions in various domains. As an authoritative figure in the industry, it's essential to prioritize trustworthiness by choosing high-quality silicone beading sourced from reputable manufacturers. Ensuring that the silicone meets industry standards and certifications is vital in guaranteeing its performance and safety. Establishing a rigorous quality assurance process can further bolster the credibility of the end product, especially in sectors where reliability is non-negotiable. In conclusion, thin silicone beading is indispensable in the effective utilization of aluminum extrusion profiles across various industries. From providing robust seals to absorbing shocks and enduring thermal stresses, the benefits of silicone beading are manifold. Understanding and leveraging these advantages require experience and expertise, underscoring its role in enhancing the durability and efficiency of aluminum structures while fostering trust in their performance. As technology advances, the significance of integrating high-quality silicone beading with aluminum extrusions will continue to grow, driving innovation and excellence in design and engineering.

Latest news

-

Best Window Seal Strip Adhesive Companies: Strong, Durable Seals

NewsAug.25,2025

-

Karcher A2004 Wet & Dry Vacuum Filter: Premium Replacement Cartridge

NewsAug.24,2025

-

Premium Vacuum Filter for Karcher VC 4, VC 6, VC 7 & Tineco A10, A11

NewsAug.23,2025

-

Hi-Flo HF155 Oil Filter KTM 250 EXC Racing 03-06 | OEM 580.38.005.000

NewsAug.22,2025

-

Leading LED Neon Rope Light Outdoor Companies & Exporters

NewsAug.21,2025

-

Top Window Seal Strip Adhesive Manufacturers & Suppliers

NewsAug.19,2025