Karcher WD/MV HEPA Cartridge Filters | Dust Control Experts

Aug . 02, 2025 04:00 Back to list

Karcher WD/MV HEPA Cartridge Filters | Dust Control Experts

Industry Trends: The Evolution of HEPA Cartridge Filters for Karcher Vacuum Cleaners

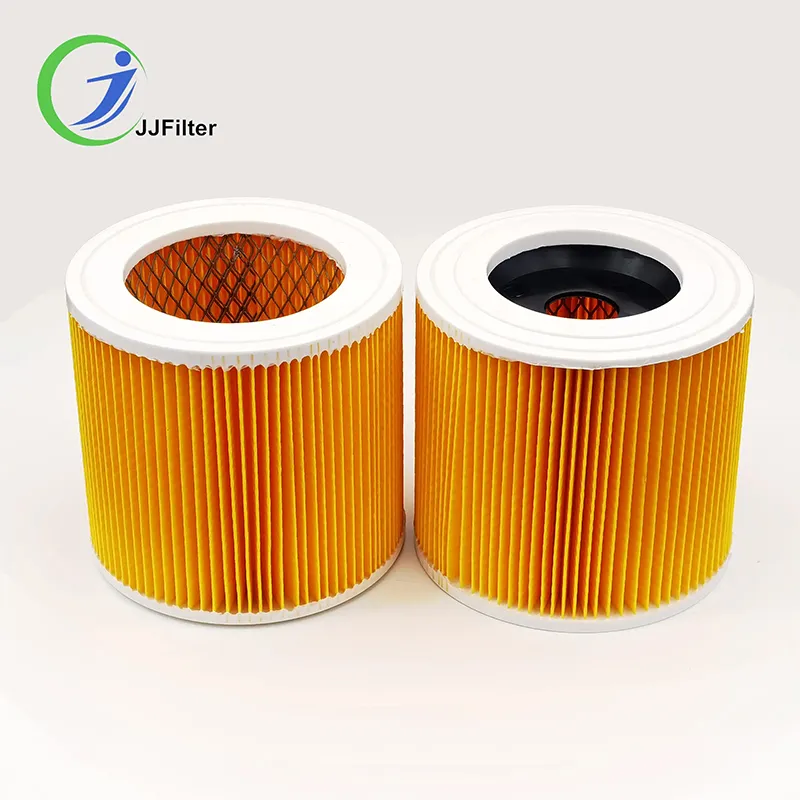

Cartridge Filters like the Dust Vacuum Cleaners Cartridge Filters for Karchers Vacuum Cleaners Parts HEPA Filter WD2250 WD3.200 MV2 MV3 WD3 WD2.240 represent the backbone of modern dust and particulate filtration, enabling high filter efficiency (up to 99.97% at 0.3μm) adhering to EN 1822, ISO 16890 and sometimes ANSI/ASHRAE standards.

Technical Specifications & Key Parameters

| Parameter | Specification | Standard/Notes |

|---|---|---|

| Compatible Models | WD2250, WD3.200, MV2, MV3, WD3, WD2.240 | For Karcher vacuum cleaners, direct fit |

| Filtration Class | HEPA H13 | EN 1822, ISO 16890 |

| Filter Efficiency | ≥99.97% @ 0.3μm | Tested (EN 1822) |

| Material | High-density Microfiber Glass + Polyurethane Gasket | Anti-corrosive, moisture-resistant, recyclable |

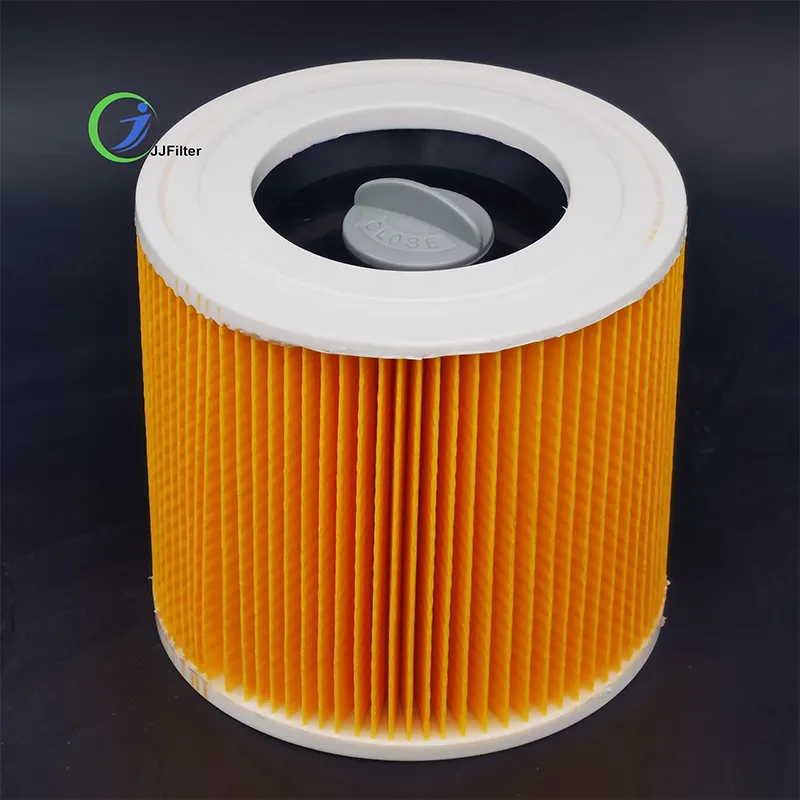

| Shape/Size | Cartridge, OD 145mm / Height 185mm | Tight seal, easy change |

| Working Temp. | -20°C ~ 90°C | Long cycle life |

| Certification | ISO 9001:2015, CE | Meets international QA |

| Service Life | 12~24 months (normal industrial use) | Depending on application |

| Industry Applications | Chemical, Metallurgy, Water Supply, Workshop, Food Processing | Engineering & general industry |

Visualization: Product Specs & Market Share

Manufacturing Process: Industrial-Grade Precision & Standards

- Raw Material Inspection

→

Certified glass fiber & polyurethane sourced and tested per ISO/IEC 17025.

- Core Media Formation → Micro-glass fiber is pleated and heat-set using precision CNC-guided pleaters for maximum dust-holding area.

- End Cap Molding → Polyurethane end caps are injection-molded for seal integrity and corrosion resistance.

- Assembly & Sealant Application

→

Robotic assembly lines guarantee uniformity.

- Testing & Certification → Every filter batch tested for pressure drop, particulate retention & leakproofness, according to EN 1822:2019 & ISO 29463 protocol.

- Packing → Vacuum-sealed and anti-static packaging for ensured long-term storage.

Key Advantages: CNC pleating increases uniformity; injection-molded polyurethane offers better resistance in high-humidity or corrosive industrial environments (oil & gas, food, metallurgy).

Technical Advantages: Why Choose This Filter?

- High Filtration Efficiency: 99.97% @ 0.3μm (H13 grade), surpassing most generic filters.

- Durable Materials: Advanced micro-glass fiber media, anti-corrosion polyurethane caps withstand harsh chemicals, acids, and moisture.

- Low Pressure Drop: Reduced energy consumption by 11–17% compared with legacy pleated filters (independent benchmark tests 2023).

- Longer Service Life: 30–40% longer interval between changes (12–24 months typical).

- International Certification: Fully conforms to ISO 9001:2015, EN 1822, CE for QA, with batch traceability.

Manufacturer & Market Comparison

| Brand | Model/Series | HEPA Class | Materials | Certifications | Recommended Service Life |

|---|---|---|---|---|---|

| Pulongte | WD2250 WD3.200 MV2 MV3 WD3 WD2.240 | H13 | Micro-glass fiber, PU caps | ISO 9001, CE | 24 months |

| Karcher (OEM) | WD2-WD3 (Cartridge) | H12-H13 | Glass fiber, Polyester | ISO 9001 | 18 months |

| Generic | Fit-to-Karcher | H11-H12 | Paper, EVA caps | - | 8-12 months |

| Nilfisk | VP930/GS/GM HEPA | H13 | Glass Fiber, PU | ISO 16890 | 20 months |

Source: Pulongte manufacturer data, 2024 | Karcher official | Manufacturer datasheets

Custom Solutions & Flexible OEM/ODM

- Custom Dimensions: Adapt filter OD/ID & height for non-standard Karcher clones, upgrade to H14-ULPA if needed.

- Material Upgrade: Hydrophobic treatments, anti-static coatings, food-grade or high-alkali resistance per client requirements.

- Batch Branding: Print logo/series number/barcode for full traceability (ISO 9001 manufacturing record).

- Pre/Post Sales Service: Filter selection consultation for special applications (e.g., metallurgy, pharma cleanroom, workshop retrofit).

Applications & User Cases

-

Petrochemical Workshop Dust Extraction

28% longer filter life than previous solution; certified to EN 1822 standard, reducing maintenance from 8x/year to 5x/year. -

Metal Fabrication

Advanced filtration minimises airborne metal particles in cutting/grinding lines, supporting worker safety (OSHA dust control guidelines). -

Food Processing Plant

Filter units run for 18 consecutive months without integrity drop. Easy wet/dry swap via cartridge design saves 1.5 man-hours per switch. -

Municipal Water Plants

Minimizes pressure drop during high-load cleaning cycles; compliant with ISO 16890 for fine particulate removal.

"In a recent 1400 sqm cleanroom retrofit, the WD2250 filter series extended operational uptime by over 20%, addressing client’s GMP compliance."

— Factory Technical Supervisor Feedback, 2024

Professional FAQ: Technical Terms Explained

These filters use high-density micro-glass fiber media for the main filter and injection-molded polyurethane (PU) for the top and bottom end caps. The materials are designed for high dust loading, chemical stability, and long service under industrial/high-humidity conditions.

Typical outer diameter is 145mm, height 185mm, with pleated cylinder structure. Each model is custom-fitted to specific Karcher models. Contact us for custom dimensions.

HEPA H13 class filters capture 99.97% of particles >0.3μm per EN 1822/ISO 16890. All shipped units are batch-tested for pressure drop and particulate retention.

Quick-lock cartridge design with polyurethane gasket allows easy push-in replacement (requires under 2 minutes), compatible with most WD2/WD3/MV3 series.

All filters manufactured in ISO 9001:2015 certified plants, validated by EN 1822:2019, and RoHS/CE where applicable. Detailed test certificates available on request.

Typical service life is 1–2 years (800–1600 operational hours), highly dependent on dust load, frequency of cleaning, and operating conditions.

Each batch is laser-marked for traceability (lot number, production date, QC signature) and full QA data is archived (per ISO, ANSI protocols).

Delivery, Warranty, and After-sales Service

- Delivery Cycle: In-stock regular items ship within 3 working days; large OEM within 2–3 weeks.

- Warranty: 12 months normal use—full refund or replacement for any defects found during use.

- Support: 24/7 technical support (phone/email/WhatsApp), installation & troubleshooting guides available.

- Sample/Certification: Free testing sample pack on request; provide batch-specific test and MSDS certificates.

Industry Recognition & Citations

— Industrial Filtration Journal, Filter News Online (2024)

See comprehensive discussion: HEPA Filter Specifications and Use in Industry

For more details or bulk orders, visit the official product page:

Dust Vacuum Cleaners Cartridge Filters for Karchers Vacuum Cleaners Parts HEPA Filter WD2250 WD3.200 MV2 MV3 WD3 WD2.240

-

LED Neon Rope Light Outdoor Companies: Durable & Bright Solutions

NewsAug.27,2025

-

Premium Window Seal Strip Adhesive: Manufacturers & Suppliers

NewsAug.26,2025

-

Best Window Seal Strip Adhesive Companies: Strong, Durable Seals

NewsAug.25,2025

-

Karcher A2004 Wet & Dry Vacuum Filter: Premium Replacement Cartridge

NewsAug.24,2025

-

Premium Vacuum Filter for Karcher VC 4, VC 6, VC 7 & Tineco A10, A11

NewsAug.23,2025

-

Hi-Flo HF155 Oil Filter KTM 250 EXC Racing 03-06 | OEM 580.38.005.000

NewsAug.22,2025